Introduction

This is the most comprehensive online guide about check valves. You will learn:

- The definition of Spring Check Valves

- The definition of Swing Check Valves

- How Spring Check Valves differ from Swing Check Valves

- Different types of Spring Check Valves

- Various Swing Check Valve types

- Connection methods for both valve types in pipelines

- And much more...

Chapter One – What is a Spring Check Valve?

A spring check valve permits unidirectional flow while blocking reverse flow. It contains a single inlet and outlet, with proper spring selection being crucial for operation. Like all check valves, it features a directional arrow indicating flow orientation. Commonly called non-return or one-way valves, these devices use spring pressure on a disc to seal against backflow.

Spring Check Valve from Check-All Valve Mfg. Co

Spring Check Valve from Check-All Valve Mfg. CoProper valve operation requires differential pressure with flow moving from high to low pressure. The inlet-side cracking pressure must overcome the internal spring force to allow flow.

All check valves restrict media to single-direction flow, using various mechanisms like balls, discs, pistons, or poppets. Spring check valves specifically prevent reverse flow during pressure drops or reversals, protecting system components.

Chapter Two – What is a Swing Check Valve?

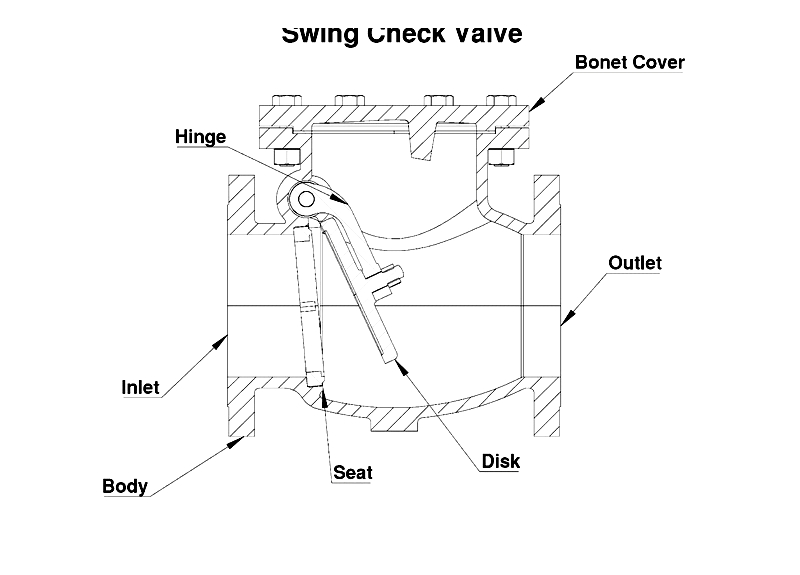

Swing check valves permit one-directional flow and automatically shut when cracking pressure drops. These butterfly-style valves feature a hinged disc that covers the opening. The disc swings open when struck by media flow, with a body arrow indicating proper flow direction.

Flow pressure opens the disc for media passage, while reverse flow forces it closed. These self-actuating valves require no external power and allow unobstructed media flow. While typically installed horizontally, they can function vertically with upward flow.