Introduction

This article provides comprehensive information about shell and tube heat exchangers.

You'll explore various topics including:

- What are shell and tube heat exchangers?

- Design principles of shell and tube heat exchangers

- Working mechanism of shell and tube heat exchangers

- Different types of shell and tube heat exchangers

- And more...

Chapter One: What is a Shell and Tube Heat Exchanger?

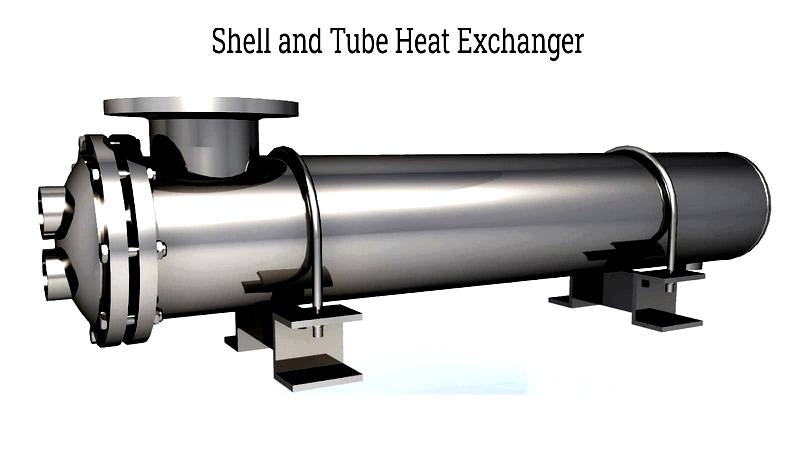

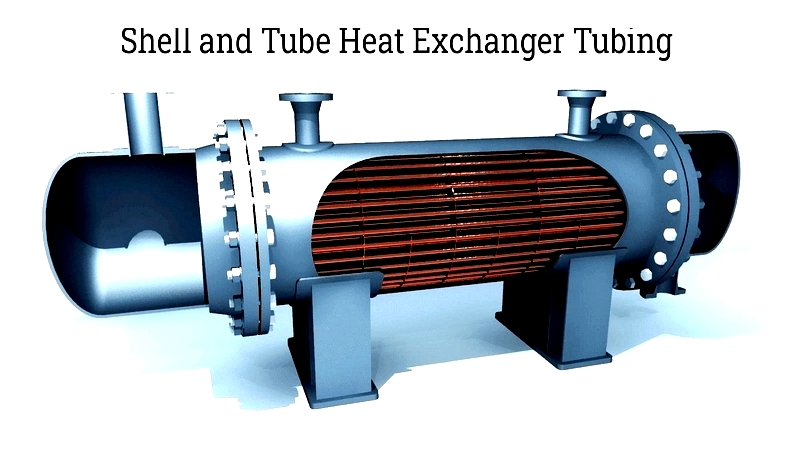

A shell and tube heat exchanger (STHE) is a widely used device designed for thermal energy transfer. It consists of a large cylindrical shell containing multiple parallel tubes. These tubes are arranged to facilitate heat transfer between two separate fluids. Known for their efficiency and versatility, shell and tube heat exchangers come in various designs to suit specific applications, tube configurations, and different characteristics.

These heat exchangers are popular for their simple yet effective heat transfer design. They function by circulating fluid or steam through the shell, which then heats the internal tubes. Optimal performance is often achieved by passing the fluid through the tubes four times, a method that enhances heat transfer efficiency.

Chapter Two: Key Considerations in Shell and Tube Heat Exchanger Design

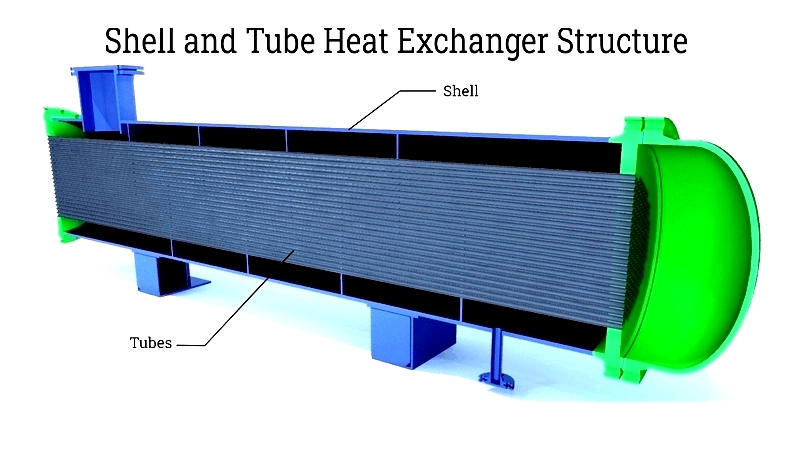

Shell and tube heat exchangers are extensively used in industrial processes due to their reliability, versatility, and adaptability to various heat transfer applications. Designing these exchangers requires advanced computational methods and precise engineering parameters to maximize thermal efficiency, mechanical integrity, and operational safety. Key components include the shell, shell cover, tubes, channel, channel cover, tube sheet, baffles, and nozzles. Design and manufacturing standards are regulated by the Tubular Exchanger Manufacturers Association (TEMA) and often comply with ASME codes.

Before manufacturing, critical data must be collected, including flow rates, temperature ranges, pressure ratings, and fluid properties. Fabrication details like tube count, dimensions, and shell diameter significantly impact performance. Thermal calculations and mechanical specifications ensure the exchanger meets specific operational requirements, optimizing heat transfer while minimizing energy loss and maintaining safety.

Shell

The shell is typically made from high-grade pipes or welded metal plates, chosen for their ability to withstand high pressures, extreme temperatures, and corrosive fluids. Common materials include carbon steel, stainless steel, and special alloys. The internal diameter is carefully designed to minimize bypass and maximize thermal efficiency while preventing performance-reducing dead zones.

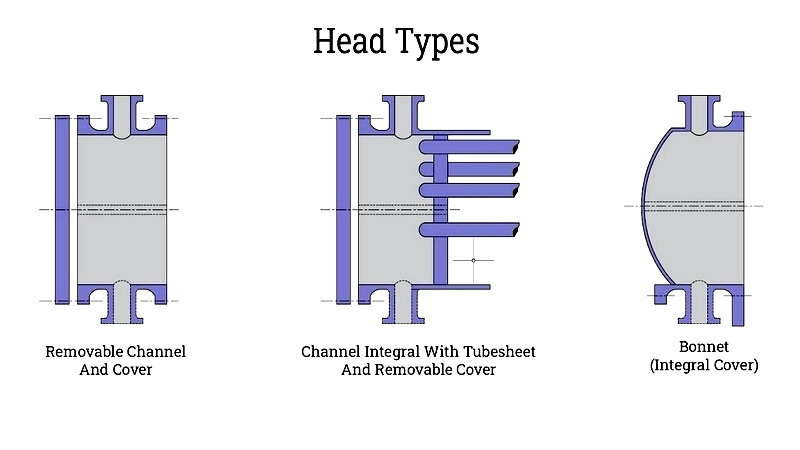

Channels or Heads

Channel or head selection depends on maintenance needs and cleaning requirements. Bonnet-type heads are used when minimal maintenance is needed, while removable covers are chosen for applications requiring frequent inspection or cleaning. These considerations are particularly important in industries like food processing and petrochemicals where sanitation and uptime are crucial.

Tubes

Tubes serve as the primary heat transfer surface, typically made from materials like carbon steel, stainless steel, or specialized alloys. Standard diameters range from 0.625 to 1 inch, with lengths varying from 6 to 24 feet. Tube arrangement affects heat transfer efficiency, cleaning ease, and fouling rates. Specialized tube designs can enhance performance in demanding applications.

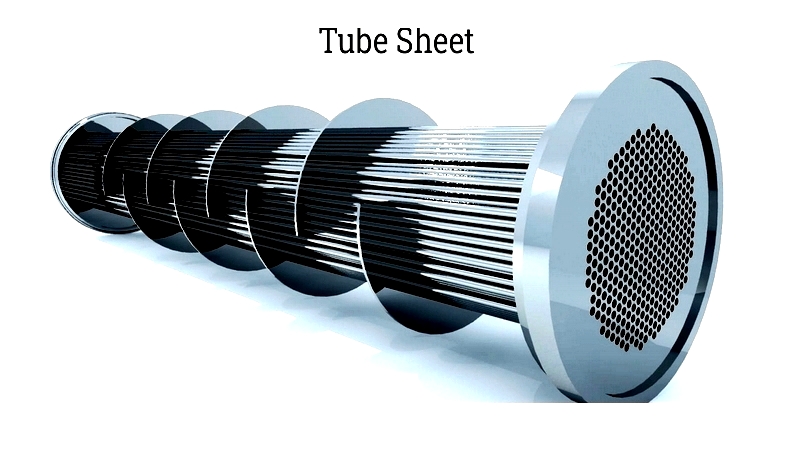

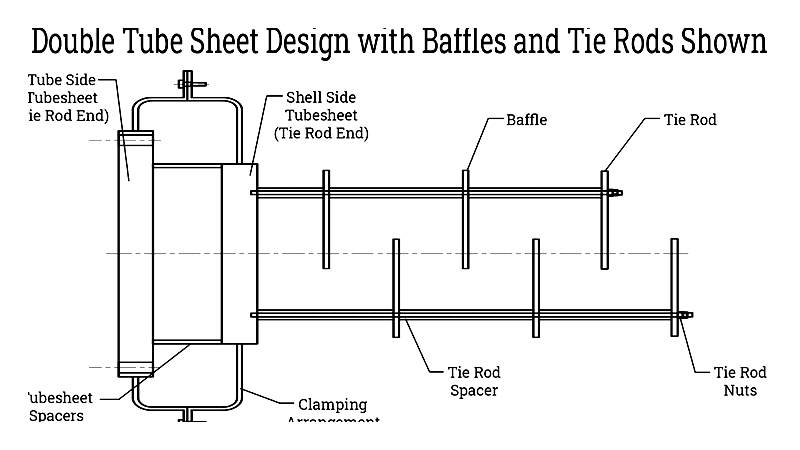

Tube Sheet

The tube sheet is a precision-machined plate that anchors the tube bundle. Made from corrosion-resistant materials, it ensures mechanical integrity under high-pressure or temperature cycling conditions. Proper design prevents leakage and maintains system safety.

Expansion Joint

Heat exchangers experience thermal expansion from temperature differentials. Without proper accommodation, this can lead to mechanical failures. Expansion joints absorb these stresses, protecting critical components and ensuring long-term durability, especially in high-temperature applications.

Shell and Tube Heat Exchanger, with expansion joint, from Enerquip, LLC

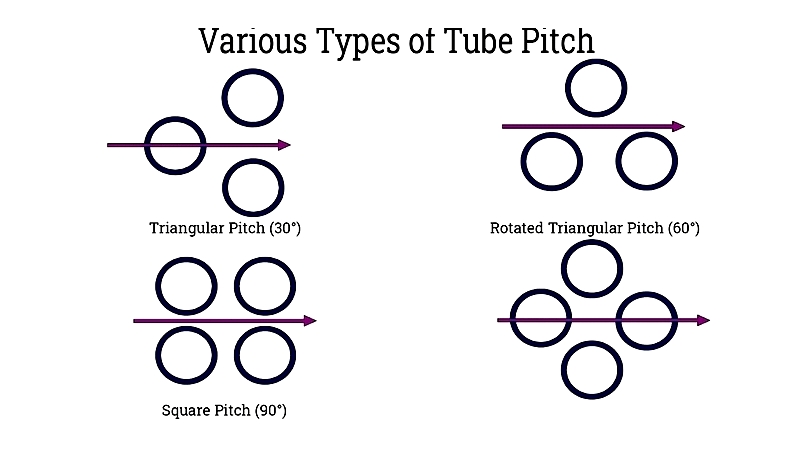

Shell and Tube Heat Exchanger, with expansion joint, from Enerquip, LLCTube Pitch

Tube pitch, the distance between adjacent tubes, affects flow patterns and heat transfer efficiency. Square pitch facilitates cleaning, while triangular layouts enhance turbulence and heat transfer. Proper pitch selection optimizes performance and energy consumption.

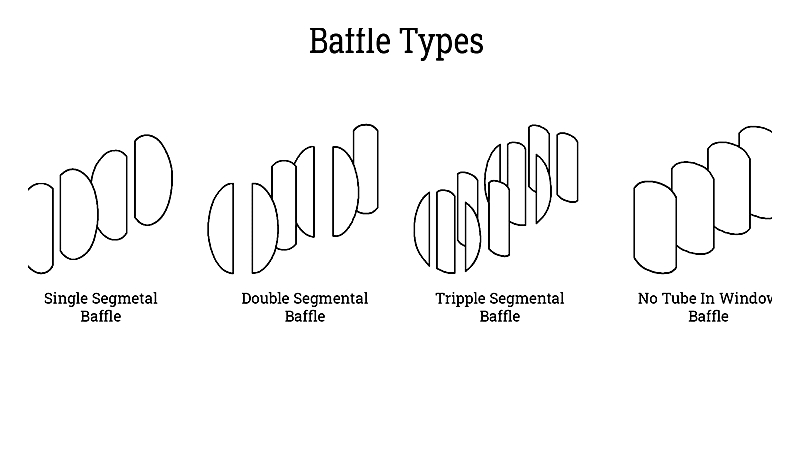

Baffles

Baffles direct shell-side flow, increasing turbulence and heat transfer while reducing fouling. Their design impacts pressure drop, heat transfer rate, and tube support. Proper baffle configuration is essential for optimal performance and reduced maintenance.

Tie Rods and Spacers

These components maintain baffle positioning and tube bundle stability. They ensure proper flow patterns and prevent vibration-related damage, contributing to the exchanger's mechanical reliability in demanding conditions.

Optimizing Shell and Tube Heat Exchanger Selection

When selecting an exchanger, consider thermal design, pressure/temperature ratings, materials, maintenance needs, and compliance with standards. Manufacturer support can help customize designs for specific applications. Regular maintenance and adherence to schedules ensure long-term performance.