Introduction

This article provides comprehensive information about immersion heaters.

You will learn about:

- What immersion heaters are

- Their working principle

- Various types available

- Common applications

- Manufacturing process

- And other relevant details

Chapter One – Understanding Immersion Heaters

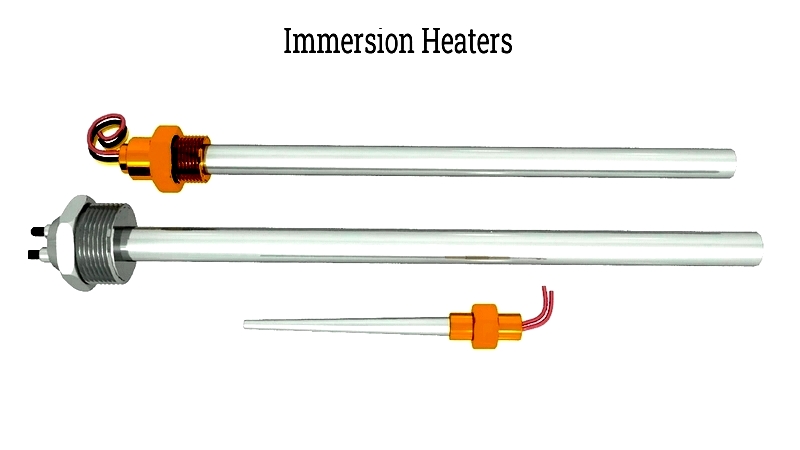

An immersion heater offers a fast, cost-effective and efficient solution for heating liquids in tanks, vats or equipment. Also known as bayonet heaters, these devices feature heating elements that can be directly inserted into containers holding water, oil or other materials to heat the entire contents.

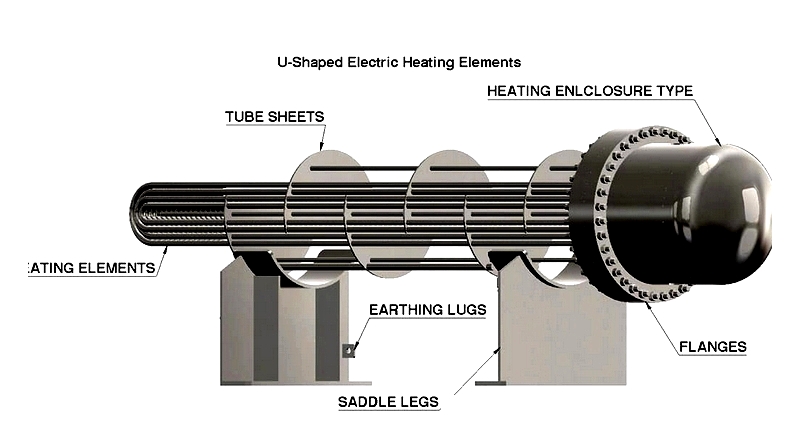

These heaters utilize direct heat transfer to rapidly bring liquids to the required temperature. Constructed with bundles of tubing, they can be mounted on container sides or fully submerged. The internal heating coils transfer heat to the liquid, ensuring even distribution throughout the container.

Immersion heaters provide an environmentally friendly heating method, delivering clean energy without residual discharge or pollutants. In nuclear reactors, they maintain constant water temperatures for steam generation.

There are two primary types: direct and indirect. Direct immersion heaters place heating elements in direct contact with the liquid, while indirect models use radiation or convection. Over-the-side and in-line heaters are direct types, while pipe and infrared heaters are indirect as they avoid direct liquid contact.

Chapter Two – Working Principle of Immersion Heaters

Immersion heaters contain electrically resistant heating elements enclosed in protective sheaths. When activated, these elements heat the surrounding jacket, which then transfers heat to the sheath and subsequently the liquid. Heating efficiency depends on the thermal conductivity of both jacket and sheath materials.

Direct and indirect heaters employ different heating methods. Direct models are inserted into the liquid through top or side fittings, with their elements contacting the fluid directly. When powered, electricity flows through the element into the liquid.

Indirect heaters are placed inside closed-end pipes immersed in the liquid. The element heats the pipe's internal air, creating an oven effect that warms the surrounding liquid. This design prevents direct contact, reducing contamination and corrosion risks.

Heating time depends on both liquid quantity and heater power. Immersion heaters are specifically designed for optimal heating efficiency with particular materials.

Immersion Heater Components

Key components to consider when examining immersion heaters include:

- Sheath material

- Power density

- Wattage

- Enclosure

- Temperature range

- Heating element

The following sections discuss each of these factors in detail.

Sheath Material

The sheath material is crucial as it directly contacts the heated fluid, with different materials reacting differently to various liquids. Manufacturers typically provide compatibility charts for specific applications.

Proper material selection is essential, as sheath failure can cause significant issues. Corrosion is the most common failure mode, and most manufacturers don't warranty against it.

Among available materials, Incoloy - a nickel-based corrosion-resistant alloy - is most widely used. It maintains superior strength at high temperatures and comes in various alloy forms to accommodate different fluids and chemicals.

Power Density

Power density must be carefully matched to the specific liquid. Incorrect density can cause liquid overheating and excessive heat buildup. The liquid's heat dissipation capability from the heating element determines appropriate power density.

Water effectively dissipates heat, allowing higher power density. Substances like crude oil and molasses require lower density due to poorer heat transfer, as shown in the following chart.

Wattage

Heater wattage determines whether sufficient heat can be delivered to reach desired temperatures, calculated based on three factors:

Startup

This phase requires maximum wattage, depending on heating method (conduction, convection or radiation) and heater type.

Operation

After startup, wattage should stabilize to maintain consistent heat flow.

Heat Loss

Heat loss considerations include liquid enclosure type, heater type and liquid characteristics, which may increase required wattage.

These factors are influenced by material properties, mass, required temperature difference and heating time.

Enclosures

Traditionally made of aluminum since mid-20th century, plastic enclosures have gained popularity for moldability but often lack quality. Most manufacturers prefer aluminum for its mechanical and thermal resistance.

Larger applications like nuclear power plants require heavier, denser metals for enclosures.