Introduction

This article provides a comprehensive discussion on aluminum coils.

After reading, you will gain a better understanding of:

- What aluminum coils are, their characteristics, and selection considerations

- The manufacturing process of aluminum coils

- Different types and grades of aluminum coils

- Applications, advantages, and disadvantages of aluminum coils

- And more...

Chapter One: Understanding Aluminum Coils - Characteristics and Selection

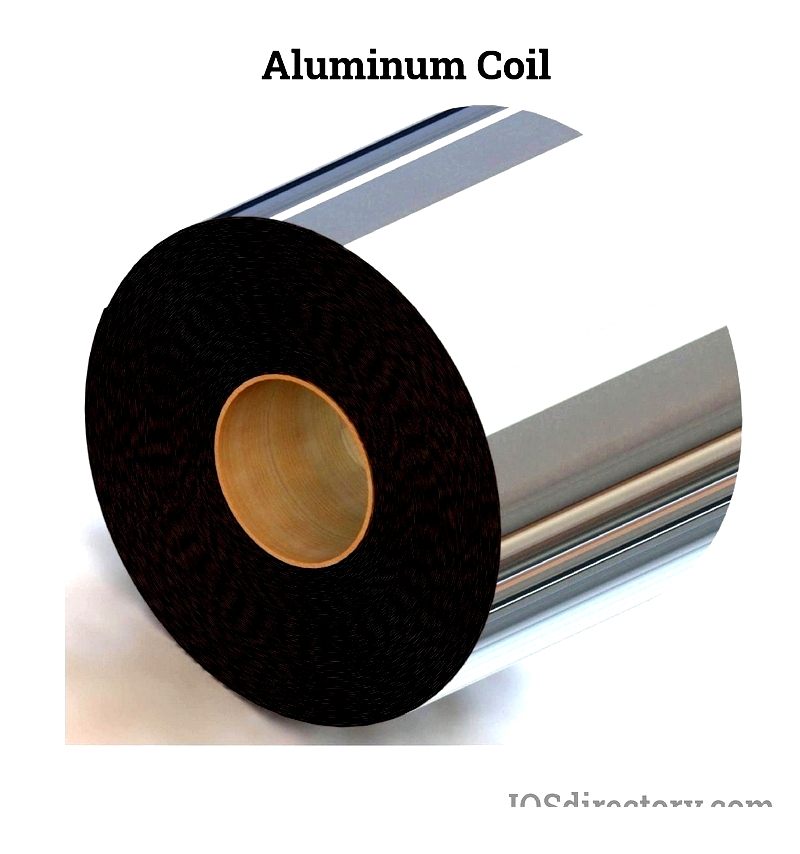

An aluminum coil refers to aluminum that has been flattened into sheets with significantly greater width than thickness, then coiled into rolls. Unlike individual sheets which are difficult to store and handle due to size inconsistencies, coiled aluminum offers convenient storage and transportation.

At metalworking facilities, aluminum coils undergo various processes including cutting, welding, bending, stamping, engraving, and assembly with other components. Suppliers provide these coils to manufacturers and fabricators who produce diverse products ranging from automotive parts to food containers.

Key Characteristics of Aluminum Coils

Corrosion Resistance

Aluminum naturally forms a protective oxide layer, making it highly resistant to weathering and corrosion, even in harsh industrial environments.

Machinability

With a lower melting point than steel, aluminum is easier to machine and cast. Its flexibility reduces processing time and costs compared to stiffer materials.

Lightweight Strength

Aluminum's low density makes it lightweight while maintaining durability, ideal for applications like aircraft construction. Its recyclability further enhances sustainability.

Non-Magnetic Properties

The crystalline structure of aluminum makes it naturally non-magnetic, with rapid oxide formation preventing sparking.

Thermal and Electrical Conductivity

Free electrons in aluminum's structure enable excellent heat and electricity conduction.

Workability

Aluminum's softness, attributed to free electron movement, facilitates bonding and processing.

Safety

Aluminum is non-toxic and safe for human contact.

Formability

Exceptional malleability allows for complex shaping, enabling designs like microchannel coils that optimize heat transfer while minimizing leaks.

Ductility

Combining low density with high corrosion resistance, aluminum is easily cast, machined, and formed into wire or other shapes.

Standard coil inner diameters include 508mm, 406mm, and 610mm, with outer dimensions determined by processing equipment. Even minor thickness variations (as small as 0.06mm) can significantly impact precision. Coil weight can be estimated using: (Coil Diameter * π/2 - Inner Diameter * π/2) * Width * 2.7 (aluminum density).

Thickness typically ranges from 0.2-8mm, with most applications using 0.2-2mm. Specialized uses may require custom thicknesses up to 8mm.

Selection Considerations

When choosing aluminum coils, consider these factors:

Supplier Qualifications

Prioritize established suppliers with proven track records. Research company history and customer feedback to ensure reliability and material quality.

Processing Requirements

evaluate machining ease, weldability, and compatibility with other materials for your specific application.

Material Grades

Consult knowledgeable suppliers to select appropriate grades balancing performance needs with cost considerations.

Formability Needs

Different alloys offer varying deformation capabilities - match this characteristic to your processing requirements.

Supply Reliability

Choose suppliers with adequate inventory to ensure consistent availability.

Application Suitability

Select grades that meet your specific performance requirements while maintaining cost-effectiveness.

Value Assessment

Balance price against quality, avoiding suppliers who compromise specifications for lower costs.

Chapter Two: Aluminum Coil Manufacturing Process

Smelting

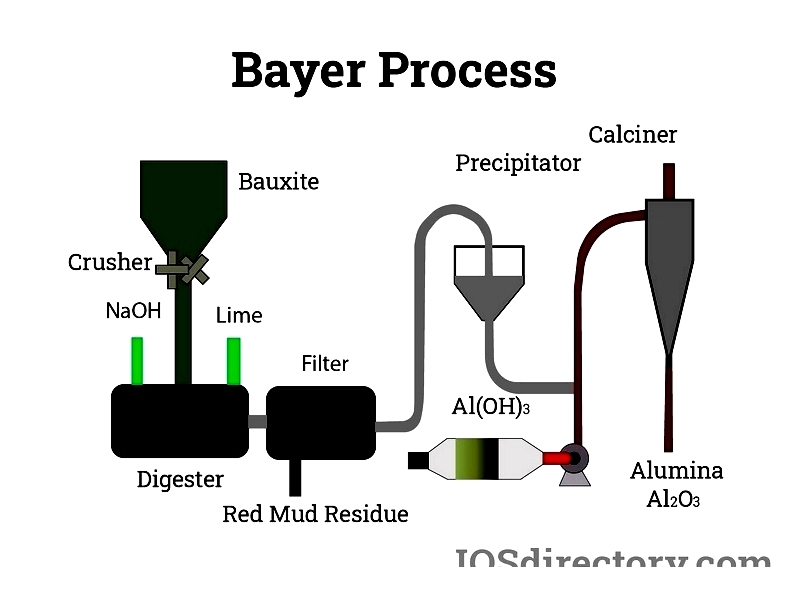

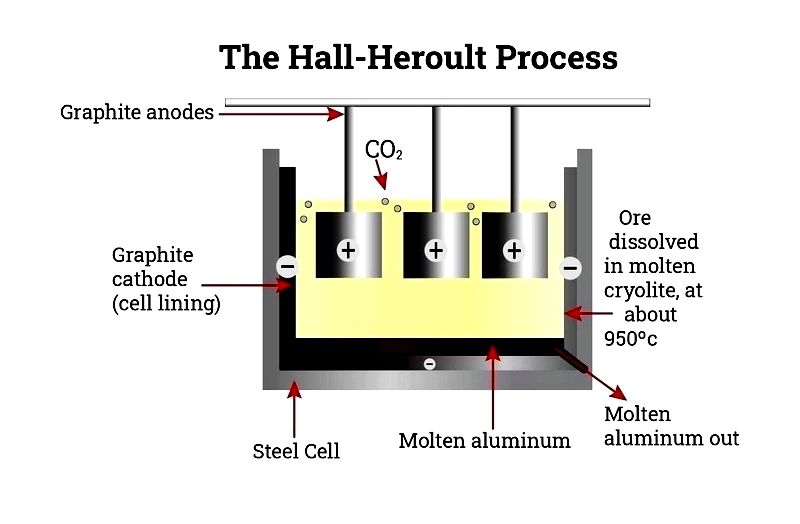

The Hall-Héroult process extracts aluminum from alumina (obtained via the Bayer process from bauxite ore). This electrolytic method uses molten cryolite to dissolve alumina, with carbon anodes producing aluminum at the cathode and CO₂ as byproduct.

The Bayer process dissolves bauxite components to extract alumina, filtering out impurities like red mud (containing iron oxides). This energy-intensive process requires substantial power, influencing aluminum production costs.

Hot Rolling

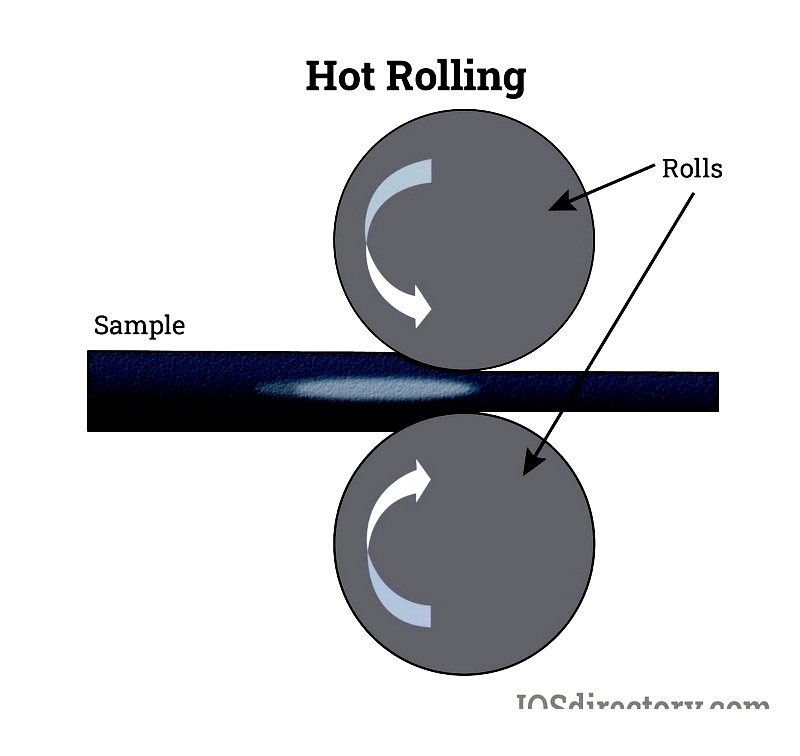

Heating aluminum above its recrystallization temperature (≈1700°F) enables thickness reduction through sequential rolling. This produces semi-finished products with less uniform thickness than cold rolling due to surface debris.

Cold Rolling

Performed below recrystallization temperatures, cold rolling increases strength and hardness while achieving precise gauges. Multiple passes through lubricated rollers gradually reduce thickness by disrupting the metal's lattice structure.

Annealing

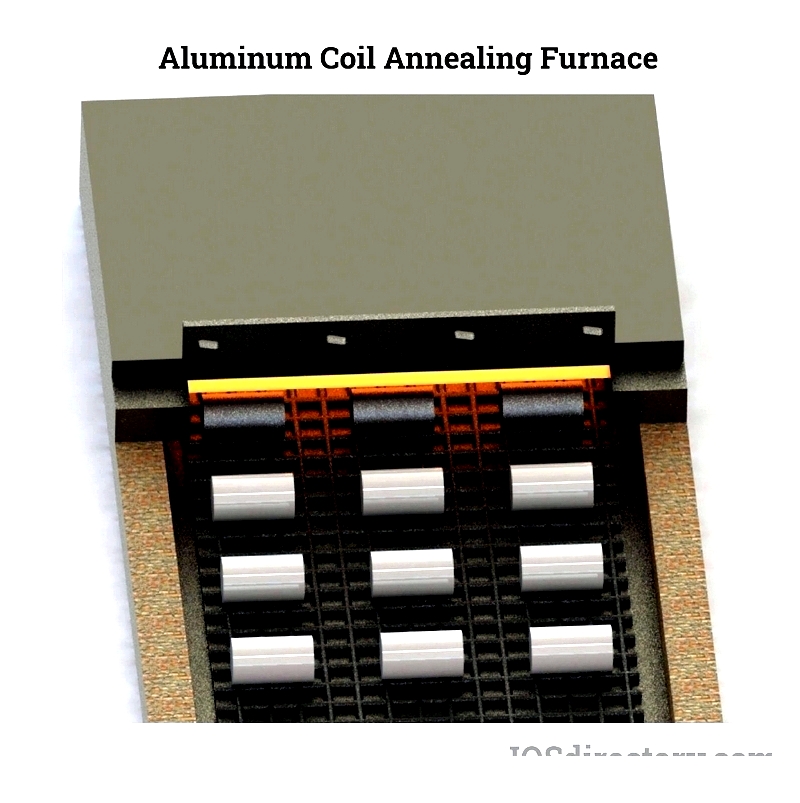

This heat treatment (570-770°F for 30min-3hrs) restores workability by resetting the crystalline structure. It improves formability, reduces brittleness, and relieves internal stresses from prior processing.

Annealing Stages

Stress Relief: Reduces internal tensions at lower temperatures

Recrystallization: Forms new defect-free grains at annealing temperatures

Grain Growth: Undesirable coarsening at excessive temperatures

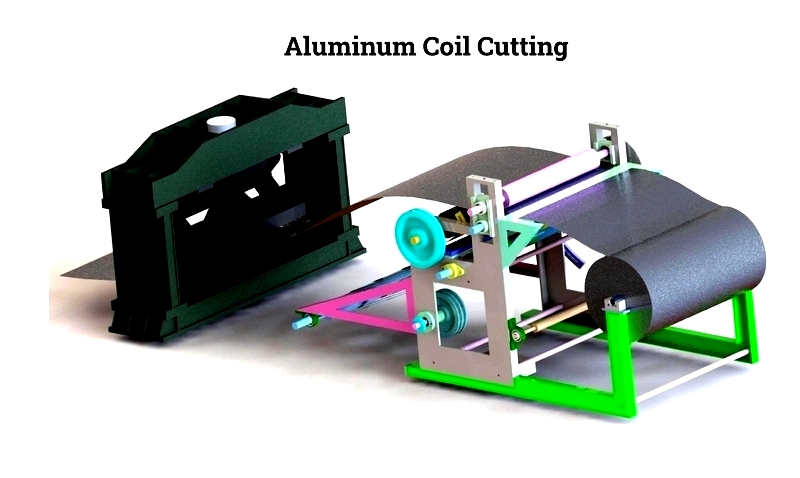

Slitting and Cutting

Precision slitting equipment converts master coils into narrower widths using sharp rotary knives. The process involves uncoiling, precision cutting with proper blade clearance, separation, and recoiling for shipment.