Introduction

This article provides an in-depth exploration of rolled ring forging.

You will gain insights into various aspects including:

- What is Rolled Ring Forging?

- The Rolled Ring Forging Process

- metals Used in Rolled Ring Forging

- Applications of Rolled Ring Forging

- Advantages of Rolled Ring Forging

- And more...

Chapter One – What is Rolled Ring Forging?

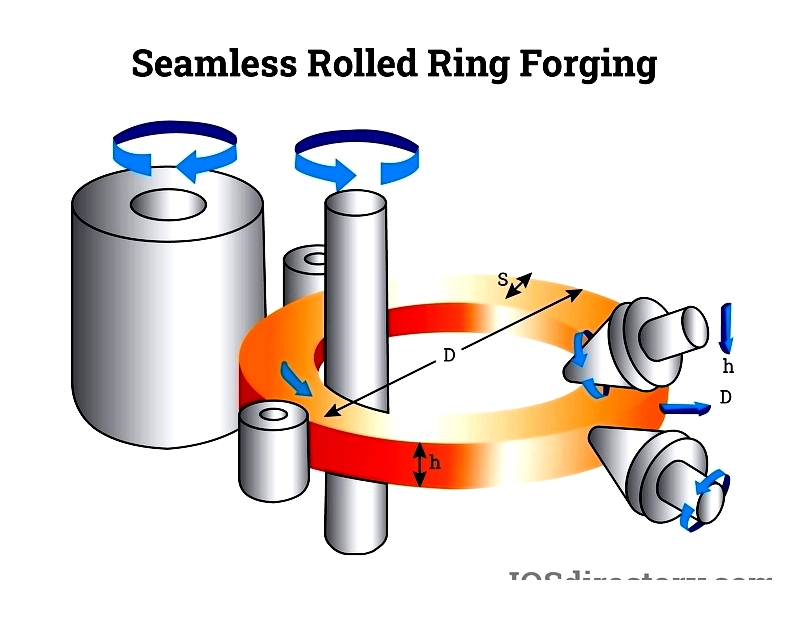

Rolled ring forging is a metalworking technique that starts with a circular, pre-formed metal piece. This initial workpiece is upset and pierced to create a doughnut shape, or torus. After heating above its recrystallization temperature, it's placed on a mandrel or idler.

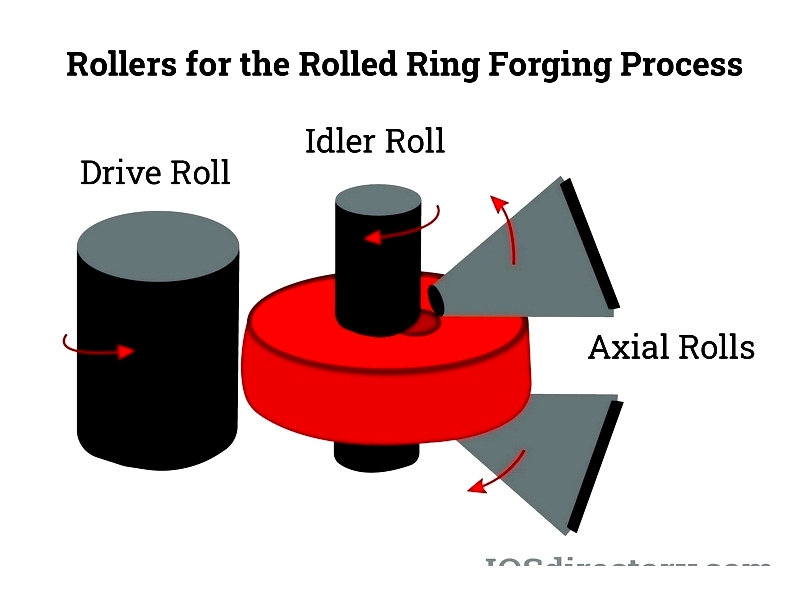

The idler directs the pierced shape toward a drive roller, which rotates continuously to reduce wall thickness while uniformly expanding both inner and outer diameters. This process yields what's known as a seamless rolled ring.

This method enables production of seamless metal rings in various sizes, perfect for applications in machine tools, turbines, pipes, and pressure vessels. It significantly improves the metal's mechanical properties while preserving its grain structure.

The forging process creates pieces with enhanced density and well-aligned grain flow. Resulting rings can weigh from a few pounds to several tons, with diameters ranging from inches to over twenty feet. Configurations include washer-like shapes and cylindrical forms, with wall-thickness-to-height ratios varying from 1:16 to 16:1.

While most rolled ring forgings feature rectangular cross-sections, specialized tooling can produce custom shapes with detailed contours on both inner and outer diameters.

As an open die forging method, rolled ring forging begins with a precisely prepared workpiece, ensuring optimal structural integrity and directional grain flow. This repeated working of the metal enhances strength, improves fatigue resistance, and eliminates voids.

Chapter Two – The Rolled Ring Forging Process

Rolled ring forging is a metalworking process valued for its cost-effectiveness, flexibility, and high-quality results. This advanced technique produces durable components ranging from small washers to large cylinders, with heights up to two feet, diameters spanning several feet, and weights exceeding six tons. A key advantage is the preservation of the metal's grain structure, as the process begins with a solid billet without melting, yielding superior mechanical properties and structural integrity.

Minimizing material waste while accommodating various ring sizes, rolled ring forging is ideal for precision metal forming. Compatible with numerous alloys including stainless steel, carbon steel, aluminum, titanium, and nickel alloys, the primary method—seamless rolled ring forging—produces rings with exceptional strength and fatigue resistance compared to welded or machined alternatives.

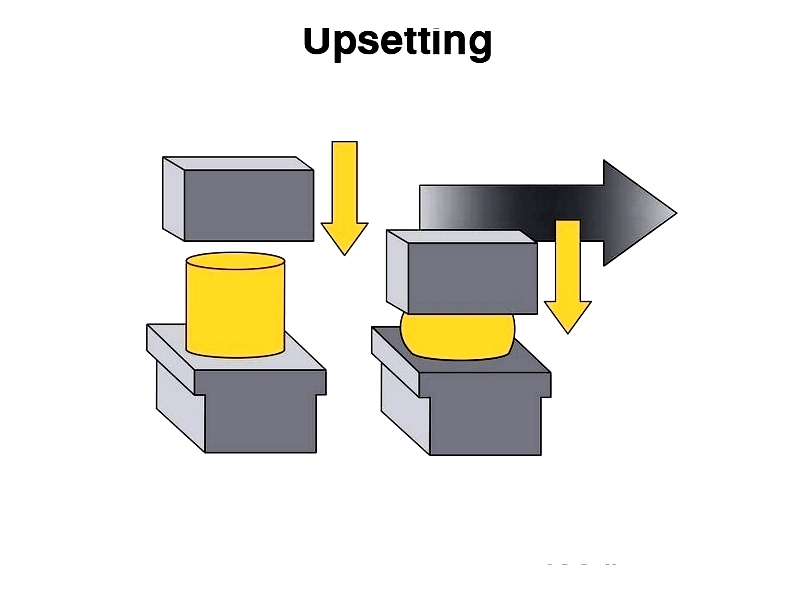

Upsetting a Workpiece

The process begins with selecting a billet—typically a solid cylindrical metal piece—and performing upsetting. This operation modifies the billet through compressive force, increasing its dimensions to prepare for subsequent processing. Usually conducted with a hydraulic press, upsetting spreads the metal along its length axis while refining grain flow for added strength.

The workpiece is heated to plastic deformation temperature and compressed between forging dies—a stage called open die forging. Heating may be done hot (for better flow) or cold (for increased hardness). At austenitizing temperature, the metal becomes more ductile, crucial for shaping critical components.

Common in fastener production, upsetting efficiently forms metal components like bolt heads. The operation increases both volume and shape, preparing the billet for subsequent piercing and rolling.

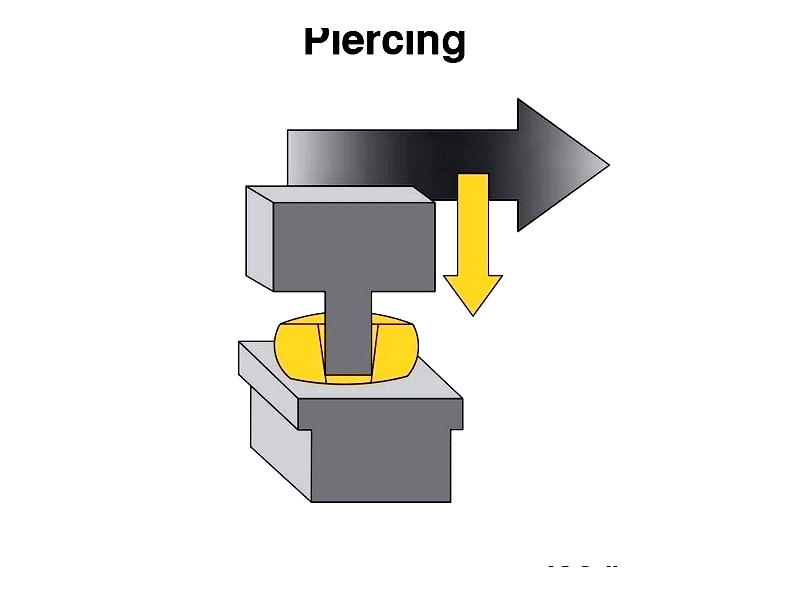

Piercing in Seamless Rolled Ring Forging

Following upsetting, the billet undergoes piercing—a critical step unique to this process. This involves punching a central hole to form a doughnut-shaped blank. The spacing between die and punch is carefully determined based on material thickness and alloy strength.

Unlike drilling, forged punching deforms the heated metal, leaving a thin web at the base. This technique enhances core integrity by controlling grain orientation, vital for high-performance applications.

While various piercing methods exist, direct punching through the billet's center is preferred for seamless rings. The removed center material is often recycled, supporting sustainable manufacturing practices.

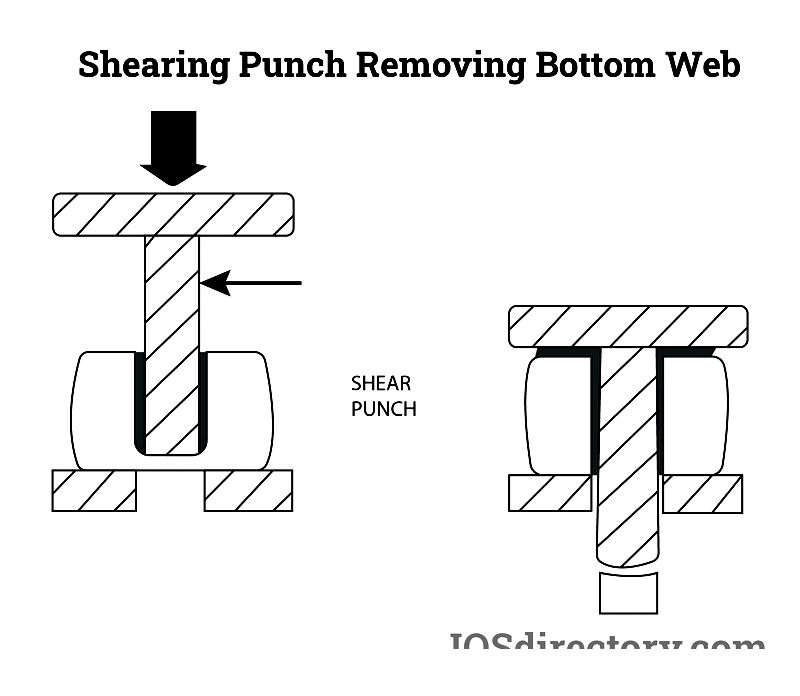

Shearing in Rolled Ring Forging

After piercing, shearing removes any remaining web to ensure a smooth internal diameter—critical for precision rings. This cold working process uses specialized tools to finalize the piercing, preparing the blank for mandrel placement.

The shearing tool makes a single stroke along the pierced hole, creating a fully open doughnut shape. This precision operation ensures smooth rotation during forging and maintains perfect circularity.

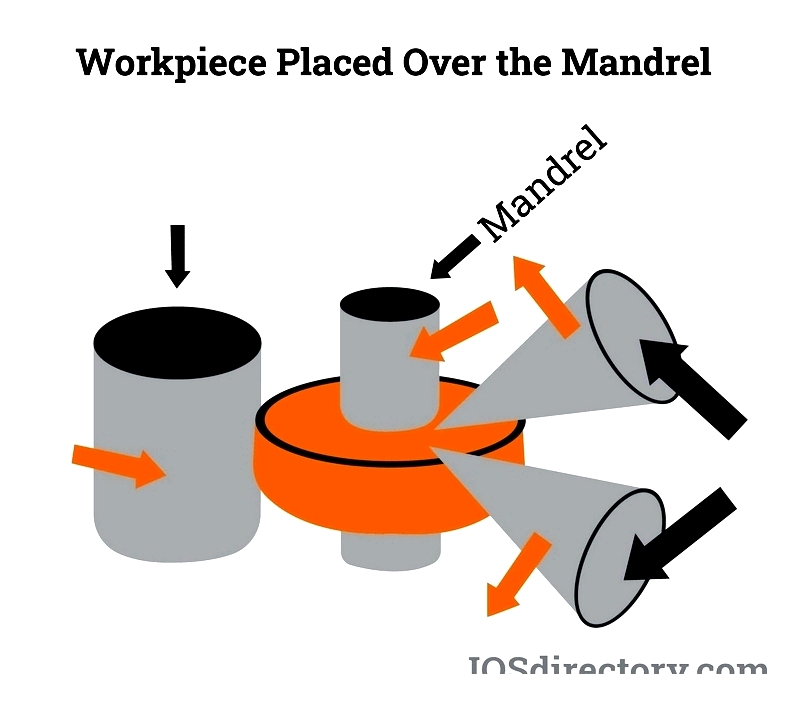

Mandrel or Idler Roller

The pierced and sheared blank is positioned over a mandrel—a robust steel rod designed for heavy loads and high temperatures. Before placement, the preform is reheated to optimize ductility.

As the blank rotates against the main drive roller, both diameters expand while wall thickness reduces. This operation is essential for custom rings, flanges, and bearing races.

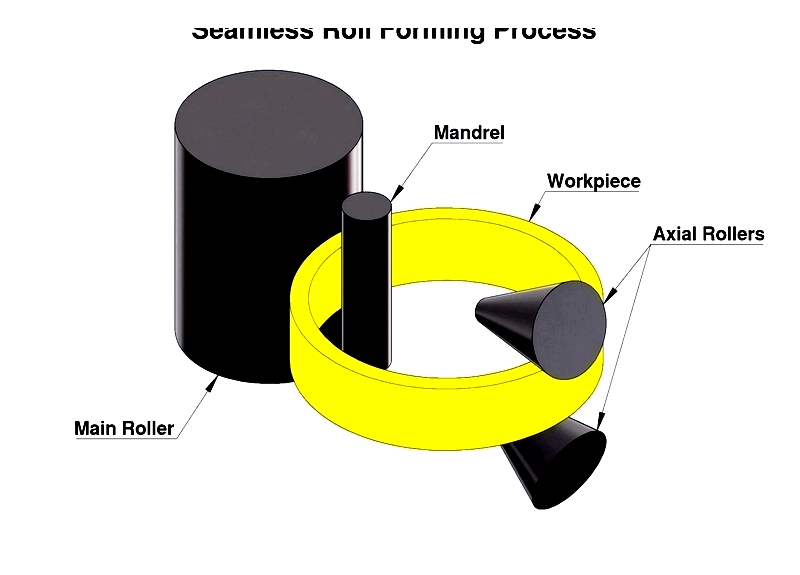

The Main Roller and Shaping Process

The main roller rotates the preform in conjunction with the mandrel, precisely expanding diameters and thinning walls. This uniform material distribution results in optimal grain flow throughout the ring.

Controlled movement during this seamless ring rolling produces high-strength, defect-free rings superior to conventional alternatives.

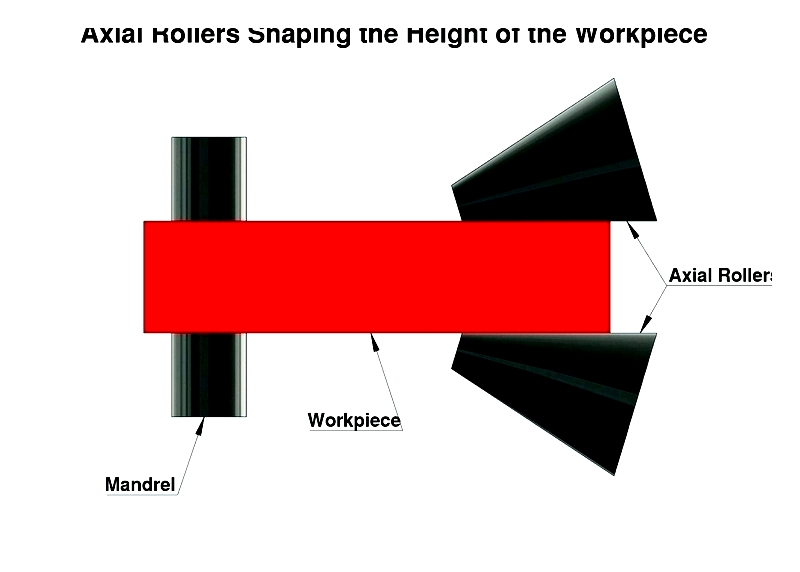

Axial Rollers

In advanced stages, axial rollers fine-tune the ring's height profile. Positioned opposite the mandrel, they exert downward force while maintaining circularity—critical for industrial forgings and bearing races.

This technology ensures dimensional accuracy and structural uniformity in the final product.

Completion of Rotation

The process continues until all dimensions meet specifications. The result is a seamless, high-strength ring requiring no additional processing—ideal for aerospace, energy, and heavy equipment applications.

Chapter Three - Rolled Ring Forging Methods

Rolled ring forging techniques are categorized by rolling orientation: radial, radial-axial, horizontal, or vertical. Each method produces distinct shapes and properties, essential for manufacturing various ring profiles used in critical applications.

Radial Axial Ring Rolling

This versatile method synchronizes main roll rotation with mandrel pressure. Upper and lower axial rollers control final dimensions, while guide rollers ensure circularity—critical for high-stress components.

Automated systems