Introduction

This page contains all the essential information about pressure transducers.

Throughout this article, you'll discover:

- What a Pressure Transducer is

- Different Pressure Reference Types

- Differences Between Pressure Sensors, Transducers and Transmitters

- Various Pressure Transducer Types

- Practical Applications of Pressure Transducers

- And more...

Chapter One – Understanding Pressure Transducers

A pressure transducer is a specialized device that converts applied pressure into a proportional electrical signal for industrial measurement applications.

Key Components of a Pressure Transducer

Pressure transducers consist of two main components: an elastic material and an electrical mechanism. Here's how each functions:

Elastic Material

The elastic material in pressure transducers varies in form and size depending on pressure range and sensing method. Its primary purpose is to deform under pressure, allowing the electrical component to measure this deformation.

Typically designed as diaphragms, these elastic elements may be made from metal discs, rubber, plastic, or leather. Diaphragms can be circular, flat, or corrugated, making them suitable for corrosive environments or systems with frequent overpressure conditions.

Electrical Device

The electrical component detects elastic material deformation and converts it into an electrical signal using resistive, capacitive, or inductive principles.

For accurate measurements, proper transducer calibration is essential, considering:

- Operating temperature range

- Reference pressure

- Ambient electrical/magnetic fields

- Mechanical vibrations

When selecting a pressure transducer, evaluate these specifications:

- Pressure sensitivity

- Measurement range

- Frequency response

- Acceleration sensitivity

Chapter Two – Pressure Reference Types and Their Impact

Pressure measurement techniques vary across industries like industrial automation, HVAC, and process control. Understanding different reference types ensures accurate pressure readings from transducers and sensors:

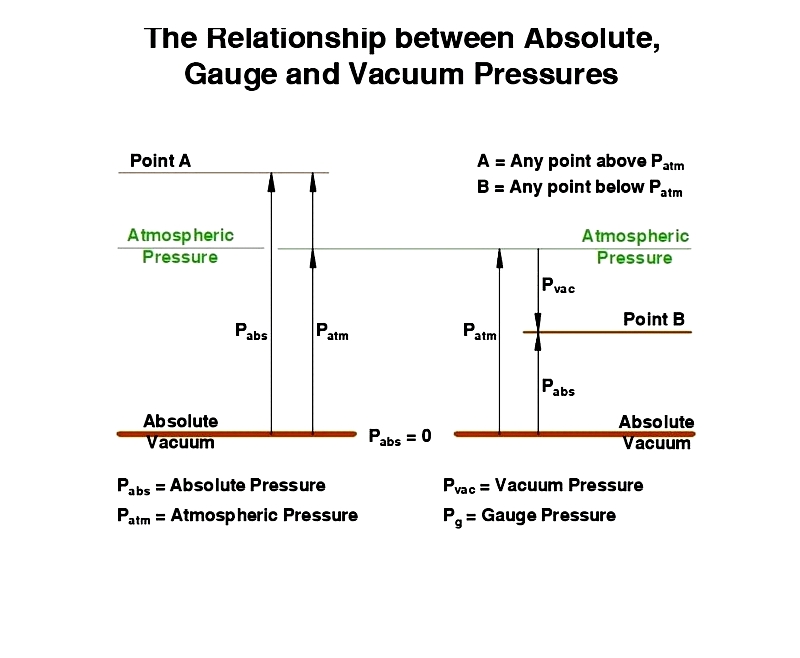

Absolute Pressure

Measured against perfect vacuum (0 Pa/psi), absolute pressure includes atmospheric and media pressure. This consistent measurement isn't affected by altitude or weather, making it ideal for barometric measurement, vacuum systems, and research. Common units are PSIA and kPaA.

Gauge Pressure

Referenced to atmospheric pressure, gauge pressure appears in devices like tire gauges. Units include PSIG, BARG, or kPaG. These vented sensors compensate for atmospheric changes but are location-dependent. Used in industrial pumps, compressors, and hydraulic systems.

Differential Pressure

Measures pressure difference between two points, crucial for flow measurement, filter monitoring, and HVAC balancing. Applications include cleanroom monitoring and liquid level measurement.

Sealed Pressure

Uses fixed reference pressure (typically 1 atm) without venting. Suitable for harsh environments where atmospheric exposure is problematic. Common in automotive, refrigeration, and aerospace applications.

Selecting the Appropriate Pressure Reference

Choosing the right reference type (absolute, gauge, differential, or sealed) ensures accurate measurements and system safety. Consider installation environment, accuracy requirements, and system specifications when selecting transducers. Leading manufacturers offer certified transducers meeting ISO, CE, or RoHS standards for optimal performance and compliance.