Introduction

This article provides an in-depth exploration of plastic crates.

Key topics covered include:

- Fundamentals of Plastic Crates

- Varieties and Configurations of Plastic Crates

- Uses and Advantages of Plastic Crates

- Additional Insights

Chapter 1: Understanding the Fundamentals of Plastic Crates

This section covers the definition of plastic crates, their manufacturing processes, applications, and benefits.

Defining Plastic Crates

Plastic crates are specialized containers designed for efficient goods transportation and storage. Made from full or partial plastic materials, they offer exceptional durability. While typically more expensive than wooden or cardboard alternatives, their extended lifespan and resilience justify the investment.

Manufacturing Process

Most plastic crates are produced using high-density polyethylene (HDPE) or polypropylene (PP). HDPE provides excellent impact resistance and UV protection, while PP offers superior scratch resistance. Additional durability can be achieved by incorporating antioxidants and UV protectants during production.

The manufacturing method depends on the crate's design and shape. Below are common production techniques:

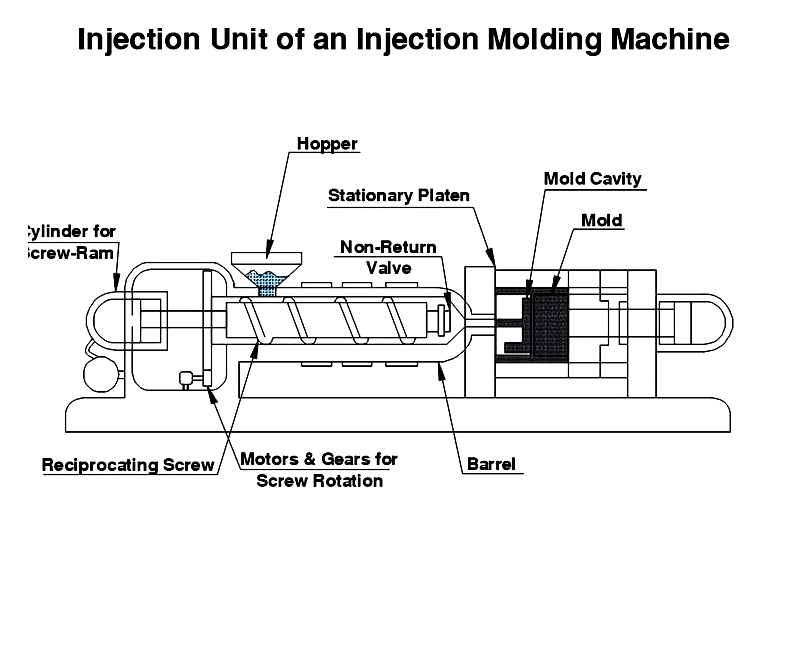

Injection Molding

This process involves three main stages:

- Melting plastic under pressure

- Injecting it into a mold

- Cooling and releasing the final product

A reciprocating screw extruder mixes materials and channels plastic into molds, which typically consist of fixed and movable halves. For hollow products, gas-assisted injection molding is preferred.

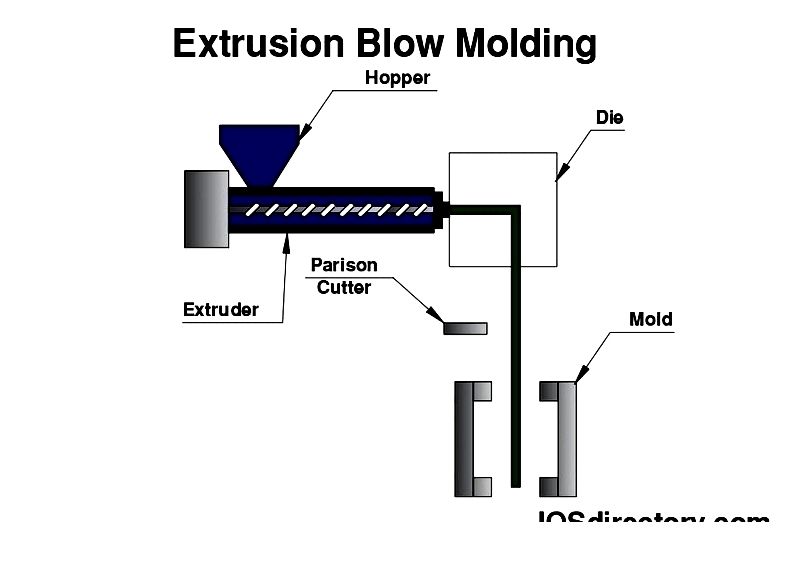

Blow Molding

This technique forms containers by expanding softened plastic within molds:

- Creating a heated plastic tube (parison)

- Clamping and inflating it in dies

- Cooling before removal

Two primary methods exist: injection blow molding and extrusion blow molding.

Extrusion Blow Molding

Forms hollow tubes shaped at one end within molds.

Injection Blow Molding

Injects plastic into molds containing air cores, using air pressure to shape products.

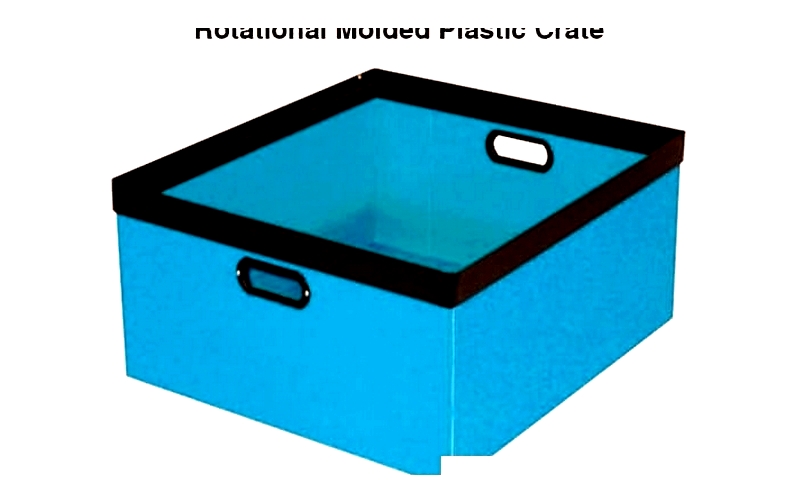

Rotational Molding

This method creates seamless hollow items by:

- Loading powdered resin into molds

- Heating while rotating

- Cooling and removing finished products

Ideal for large items like agricultural tanks and insulation boxes.

Thermoforming Techniques

Heats thin plastic sheets before shaping them over molds. Common applications include disposable food containers.

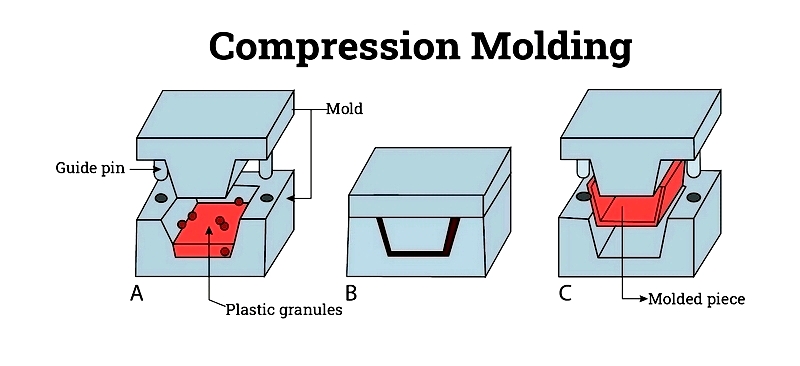

Compression Molding

Forms plastic by pressing resin between molds, particularly for large thermosetting products.

Design Considerations

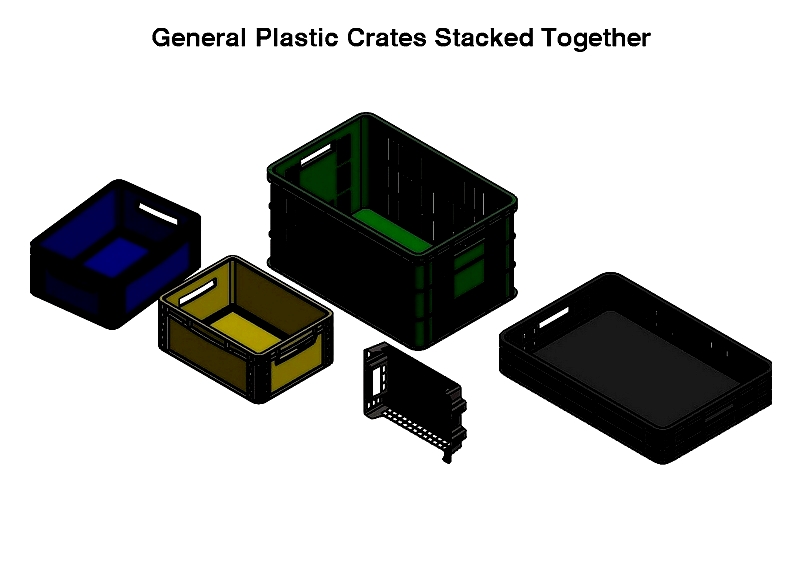

Plastic crates come in open or closed configurations, with various features for different industries. They're designed for stackability, durability, and efficient space utilization.

Chapter 2: Orientations and Types of Plastic Crates

Plastic crates have revolutionized storage and transportation, offering superior alternatives to traditional materials. This chapter examines their various configurations and applications.

Orientations

Key stacking options include:

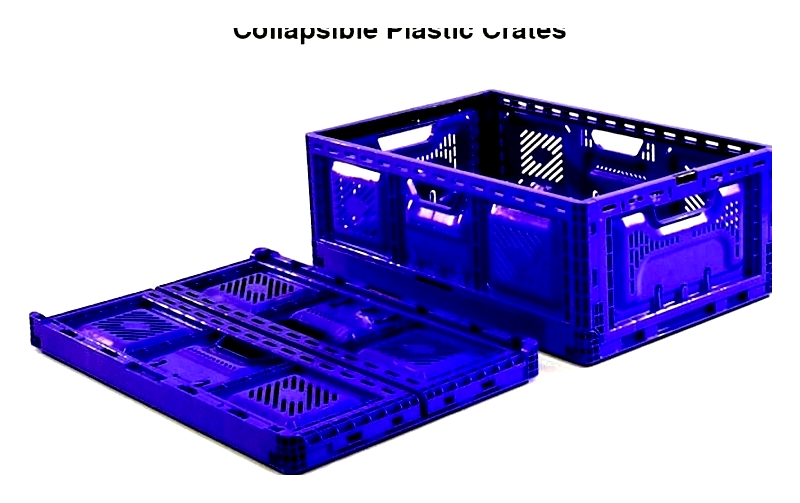

Collapsible Crates

Space-saving designs ideal for efficient return logistics.

Stacking Crates

Modular designs for vertical space optimization.

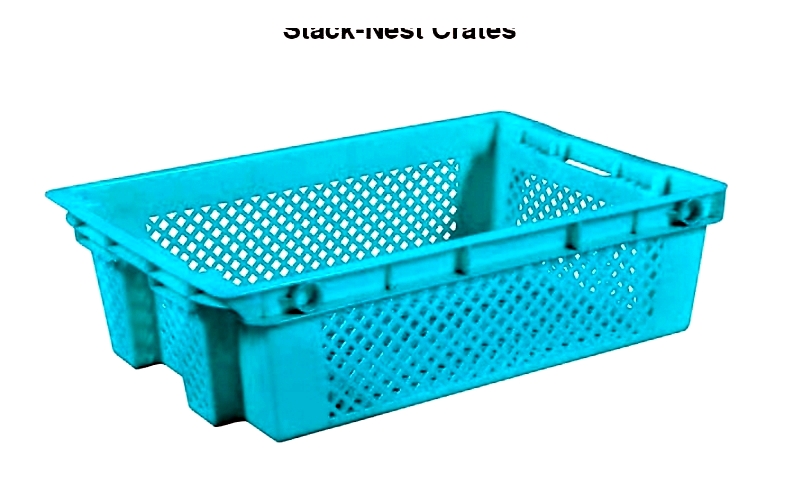

Stack-Nest Crates

Versatile designs with industry-specific features.

Swing Bar Variants

Enable quick conversion between nesting and stacking modes.

Covered Variants

Enhance product security during transport.

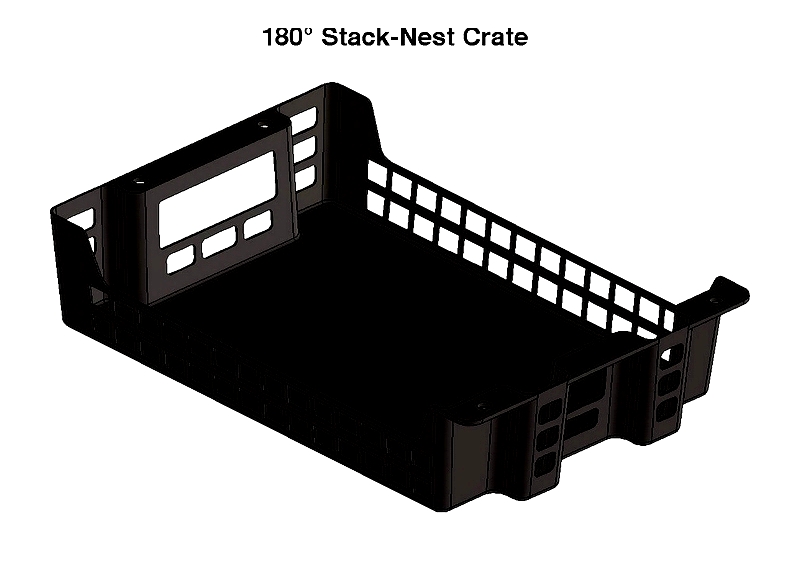

180° Rotation Models

Offer flexible stacking/nesting options.

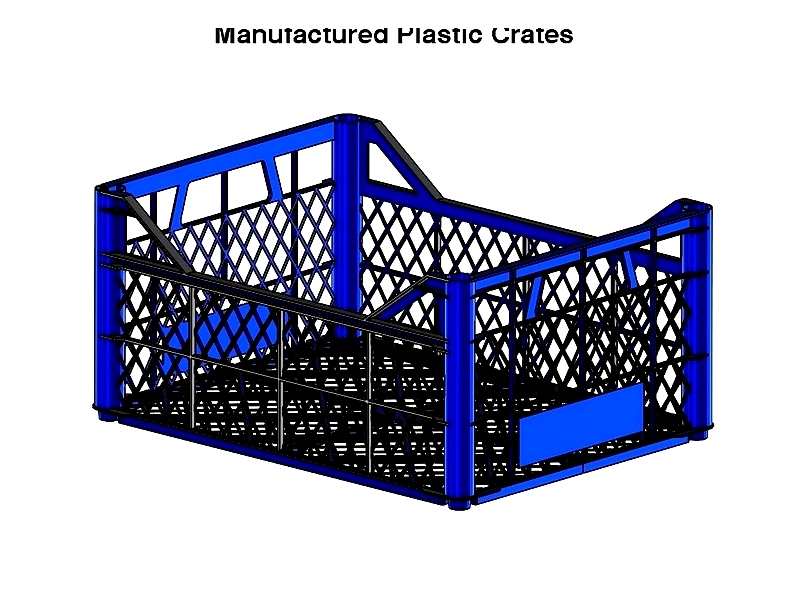

Common Types

Standard Crates

Versatile solutions for general storage needs.

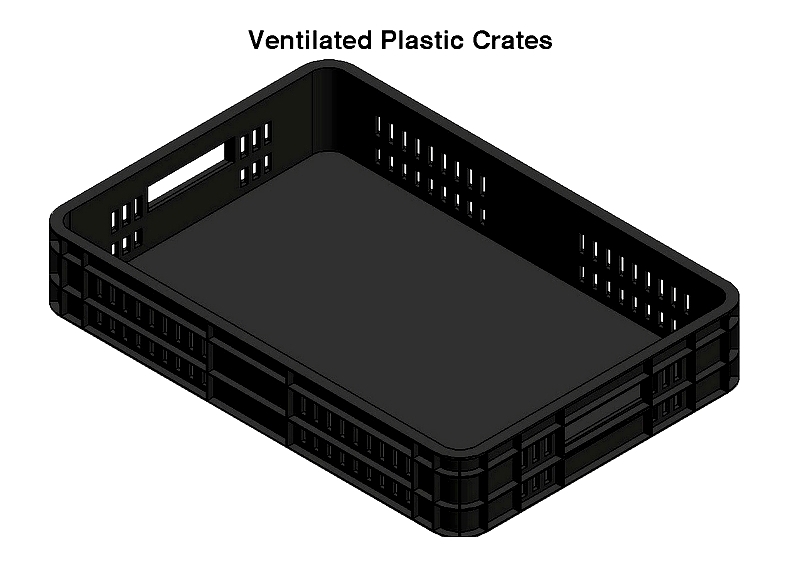

Ventilated Crates

Designed for perishable goods with airflow features.

Closed Crates

Secure containers for sensitive products.

6040 Crates

Standardized dimensions for European logistics.

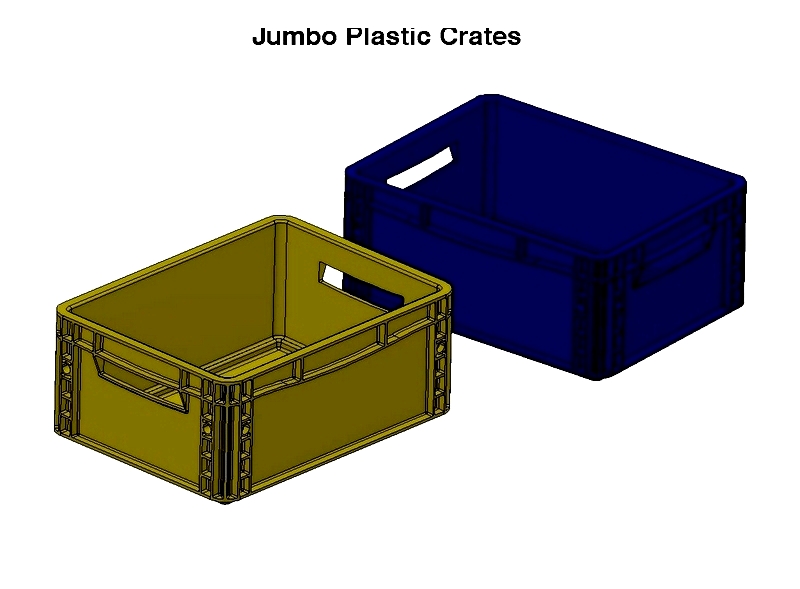

Jumbo Crates

Heavy-duty solutions for bulky items.

Specialty Crates

Custom designs for niche applications.

Comparison with Wooden Crates

Plastic crates outperform wooden alternatives in:

- Safety and ergonomics

- Space efficiency

- Ease of handling

- Environmental resistance

- Hygiene maintenance