Introduction

This article provides an in-depth exploration of locks and their applications.

You will gain insights into various topics including:

- What is a Lock?

- Types of Locks

- How to Choose a Lock

- How Locks are Made

- metals Used to Make Locks

- And Much More...

Chapter One – Understanding Locks

Locks are security mechanisms that protect entry points by engaging a latch, cylinder, bolt, or similar metal component with a strike plate. These devices restrict access to ensure privacy, security, and safety. The locking mechanism controls the movement of the latch, bolt, or shackle, either securing it in place or releasing it to unlock.

The term "lock" covers various security devices, including padlocks, combination locks, door locks, deadbolts, electric locks, and key-operated locks. Lock mechanisms may feature warded, pin tumbler, spindle, or disk tumbler designs. Locking systems are classified as key-operated, combination, or electronic.

Historically, locks were mechanical devices operated by levers, wheels, gears, and cams. Over the past century, lock technology has evolved to incorporate advanced programming, electronic components, and automated locking systems.

Chapter Two – How Locks Are Made

Locks are vital for physical security, protecting property, valuables, and buildings from unauthorized access. Available in diverse designs, mechanisms, and security levels, locks are engineered to meet various needs—from basic residential use to high-security industrial applications. Selecting the right lock and ensuring proper installation are crucial for optimal security, durability, and convenience.

Lock security ratings depend on material quality and manufacturing precision. Low-security locks, like inexpensive padlocks, often use inferior metals and are vulnerable to tampering. High-security locks, meeting ANSI/BHMA Grade 1 standards, employ hardened steel, brass, and reinforced alloys with anti-drill plates and pick-resistant features for superior protection.

Special-purpose locks, such as fire-rated, tamper-resistant, and smart locks, are designed for unique environments. These solutions withstand harsh conditions, frequent use, or vandalism. Leading manufacturers ensure compliance and reliability through rigorous testing, making them ideal for commercial and institutional use.

Making a Lock: Manufacturing Processes and Technologies

Key Locks

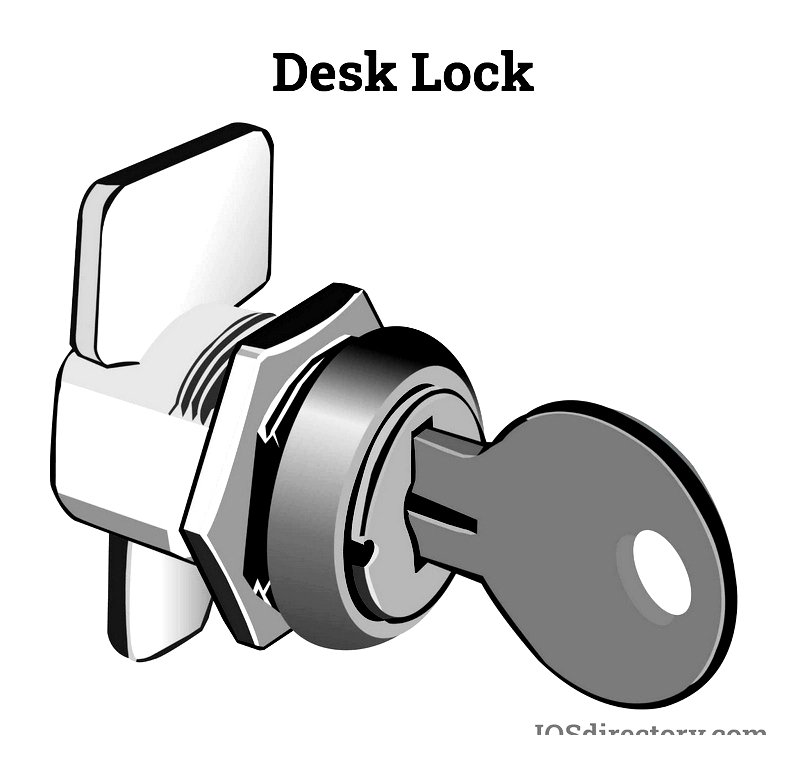

Key locks are widely used for their reliability in doors, furniture, and safes. Manufacturing involves precision engineering with materials like brass and zinc for internal components and steel for high-wear parts.

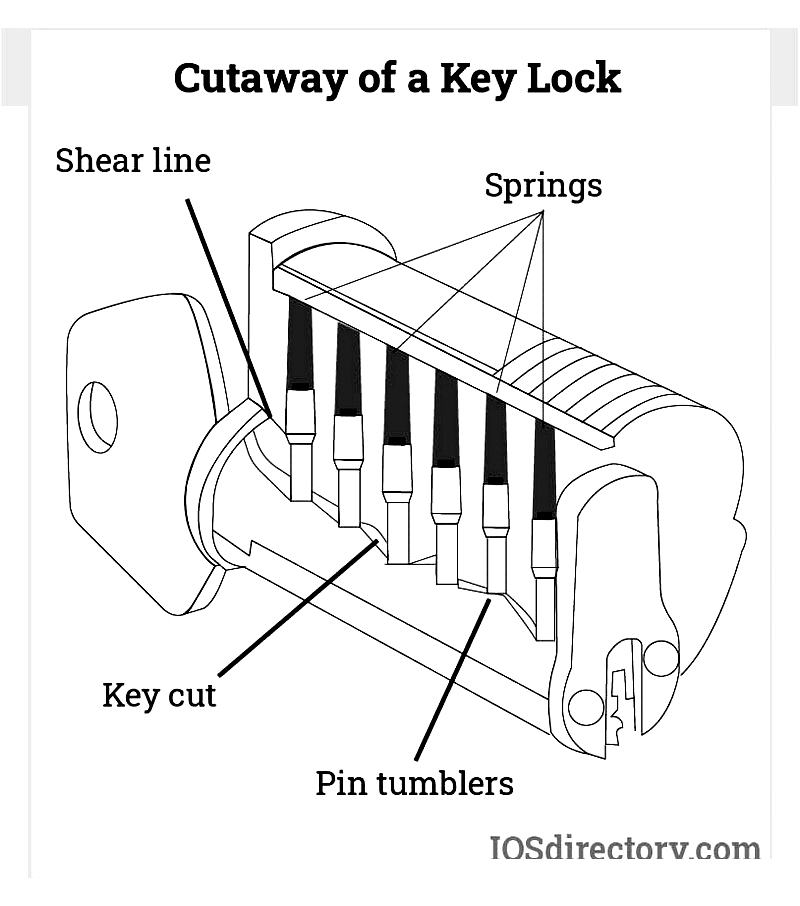

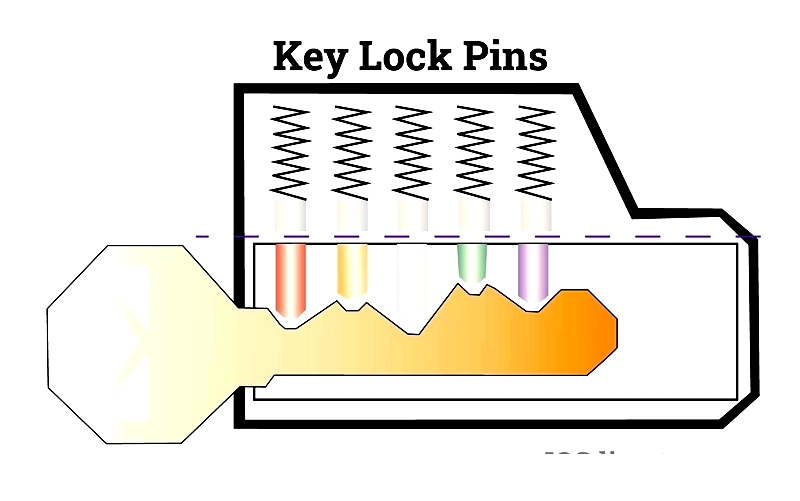

Standard pin-tumbler locks require precise key cutting and pin arrangement. Security is enhanced through mushroom pins, spool pins, and master keying systems.

High-precision CNC machinery ensures tight tolerances for pins, reducing friction and improving pick resistance.

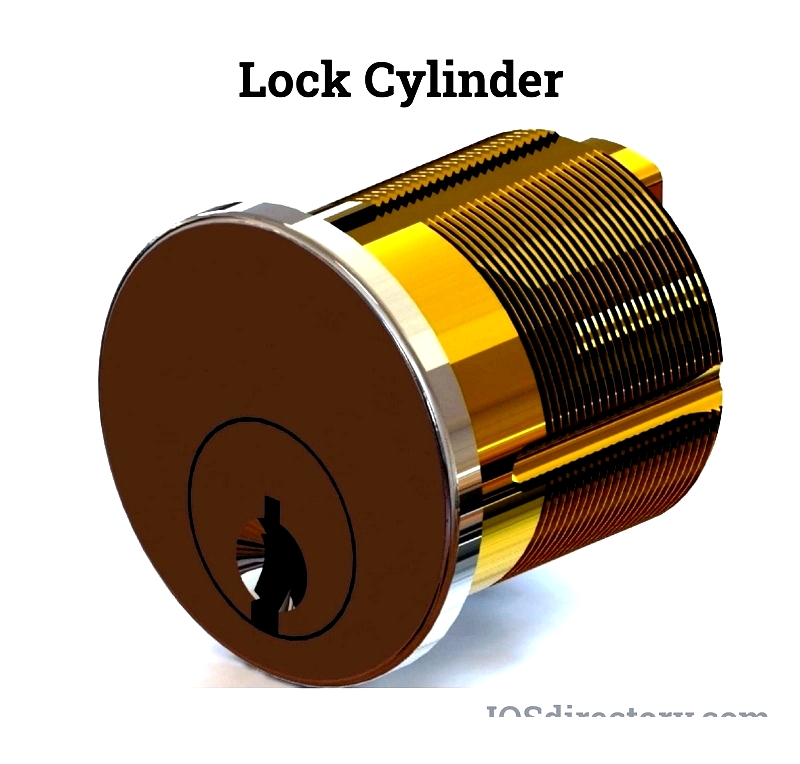

The lock cylinder, which receives the key and retracts the bolt, varies by lock type. Quality cylinders feature hardened steel inserts for drill resistance.

The bolt or latch extends into a reinforced strike plate, which must be precisely aligned to prevent forced entry.

Strike plates, made from hardened steel, enhance security with reinforced screw holes and anti-saw pins.

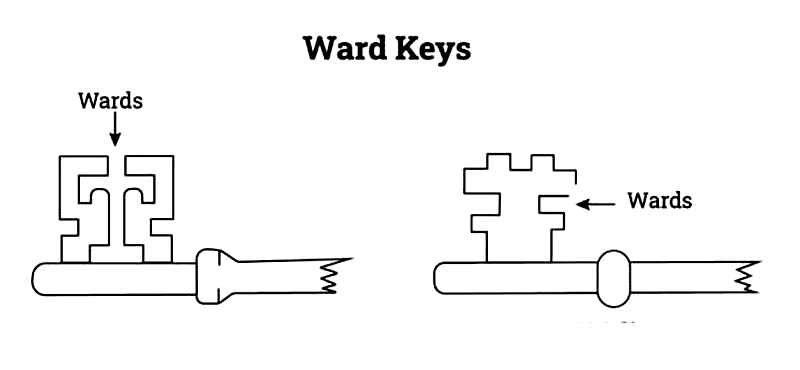

Warded locks, an early design, use obstructions to block incorrect keys. Though outdated, they remain in antique furniture.

Skeleton keys can bypass basic warded locks, but modern security standards favor advanced mechanisms.

Combination Locks

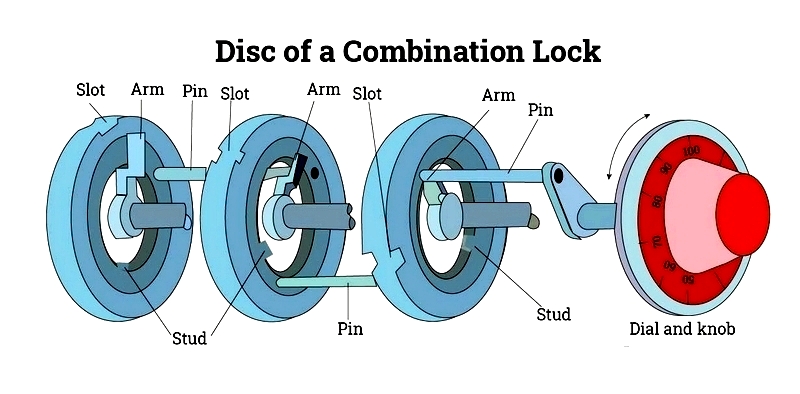

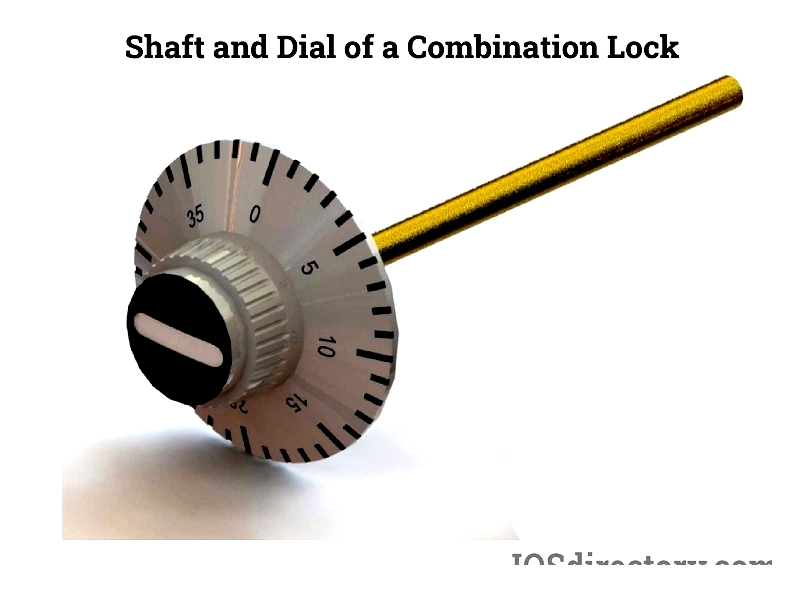

Combination locks provide keyless entry via a sequence of numbers or symbols. They are common in gym lockers and safes, using disc or wheel mechanisms.

Mechanical dial locks and electronic keypad models offer varying levels of convenience and security. Construction materials include cold-rolled steel and stainless steel for durability.

The lock case, made from hardened metal, protects internal mechanisms through processes like die casting or CNC machining.

Keyless mechanisms use rotary dials or thumb wheels to align discs. High-security models include anti-pick levers and sensors.

When discs align correctly, a lever releases the bolt, ensuring security against manipulation.

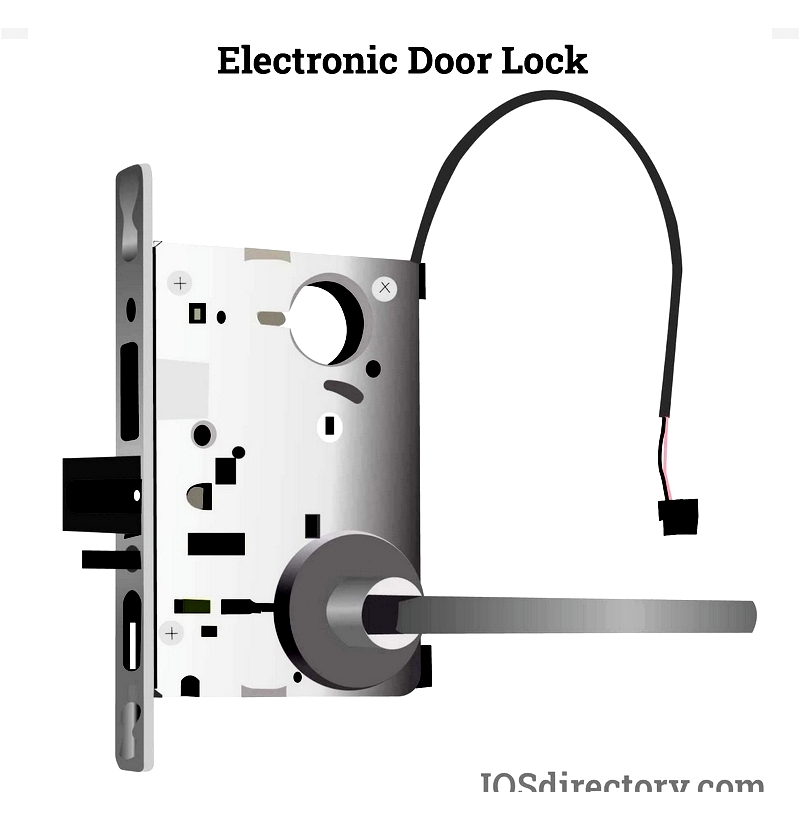

Electric Door Locks

Electric locks, or smart locks, integrate modern technology for keyless and remote access. They operate via smartphone apps, RFID cards, or biometric scanners.

Wired or battery-powered, electric locks include solenoid deadbolts and electromagnetic locks for high-security applications. Features like audit trails and multi-factor authentication enhance security.

Deadbolt Locks

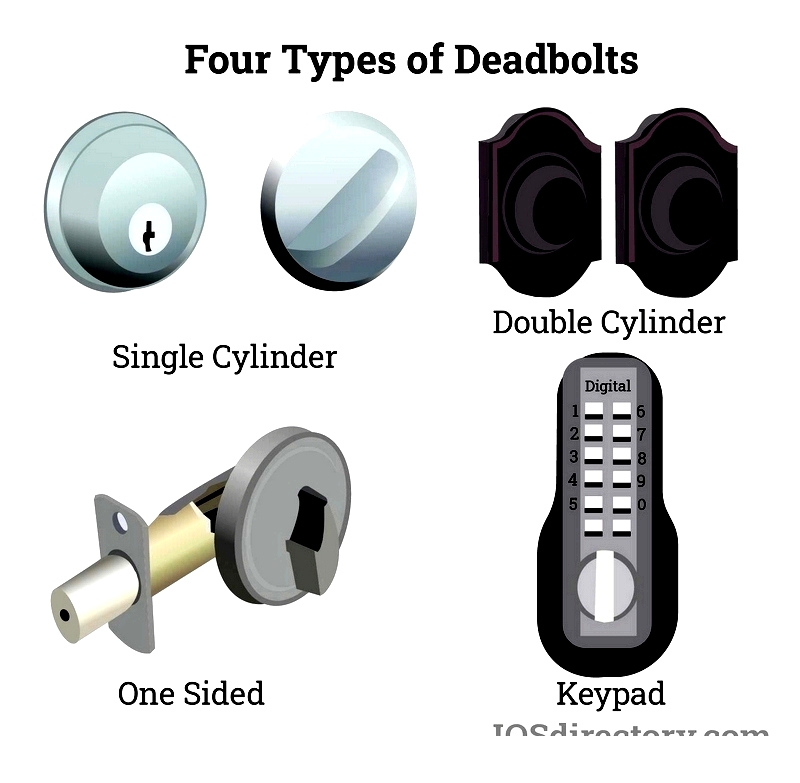

Deadbolts offer superior security with a metal bolt that extends into a reinforced strike plate. Types include:

- Single cylinder deadbolts – Key outside, thumb turn inside.

- Double cylinder deadbolts – Key required on both sides.

- One-sided deadbolts – Lockable only from inside.

- Keypad deadbolts – Digital keypad for code entry.

Modern deadbolts feature bump-resistant and drill-resistant technologies, with smart home integration for remote control.