Introduction

This article provides a comprehensive overview of industrial ovens.

You will explore key topics including:

- What Is An Industrial Oven?

- How Industrial Ovens Work

- The Components of Industrial Ovens

- Types Of Industrial Ovens

- And more...

Chapter 1: Understanding Industrial Ovens

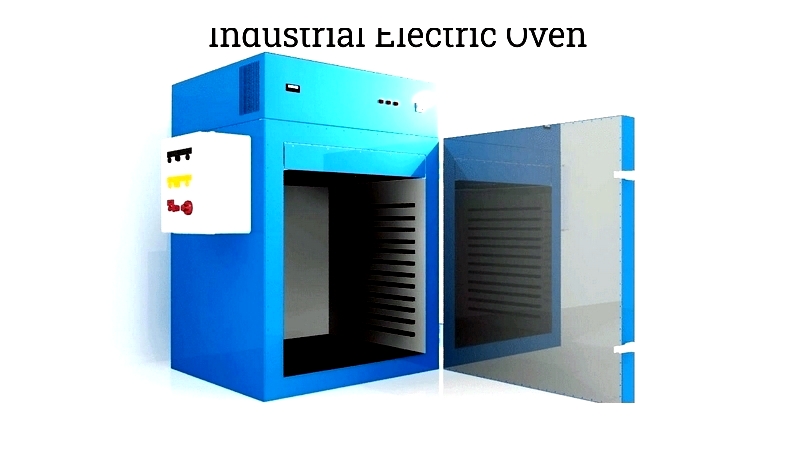

Industrial ovens are thermal processing equipment designed for drying, curing, and baking various materials across industries like chemical processing, food production, and electronics manufacturing. These processes alter product properties through heating techniques such as drying, baking, or dehydration. Industrial ovens perform diverse functions including adhesive activation, material fusion, heat setting, shrinking, preheating, sintering, melting, laminating, and thermal bonding.

These ovens operate across temperature ranges. High-temperature models, sometimes called kilns, primarily handle drying processes at lower temperatures than ceramic kilns. Lower-temperature ovens are used for baking or curing in manufacturing plants and bakeries.

Available in various sizes, industrial ovens range from household-like units to large walk-in models. Many feature conveyor systems for efficient mass heating, while others include multiple shelves for batch processing like bread baking. Mobile versions offer portability for vehicle or cart installation.

Precise temperature control distinguishes different oven types. Drying ovens remove moisture, curing ovens facilitate coating reactions, and food production ovens exceed domestic units in size and temperature capacity.

Chapter 2: How Does An Industrial Oven Work?

Industrial ovens are sophisticated thermal systems for large-scale operations, evolving from basic food processing and manufacturing applications to serve diverse industries including automotive, aerospace, and pharmaceuticals. Modern ovens support laboratory testing, powder coating, drying, heat treatment, and material processing.

Two primary categories exist: electric and gas ovens. Gas models use natural gas or propane with forced convection for even heat distribution, ideal for irregularly shaped products. They operate typically between 180°F and 500°F, with maximum temperatures near 1000°F.

Gas ovens come in direct-fired and indirect-fired configurations. Direct-fired models use open flames for rapid heating, while indirect models employ heat exchangers for sensitive materials. Though faster-heating, gas ovens may experience energy loss through air circulation.

Specialized water-based ovens provide gentle heat for proofing, aging, or delicate drying, with temperature limits around water's boiling point. These require manual or automated water filling before operation.

Electric ovens offer cleaner operation through resistance heating, with precise digital controls for applications requiring contamination-free environments. They're preferred in semiconductor and pharmaceutical manufacturing.

Selection depends on process requirements, temperature needs, efficiency goals, and compliance standards, with considerations for capacity, airflow, safety, and automation compatibility.

Chapter 3: What Are The Parts Of An Industrial Oven?

While designs vary, industrial ovens share fundamental components: motors, exhaust systems, ductwork, temperature controls, and heating elements. Understanding these parts aids in specification and purchasing decisions.

Motors and Power: Specialized motors drive fans, blowers, and conveyors, affecting temperature consistency and efficiency. Variable speed options enhance control in high-volume settings.

Exhaust Systems: These maintain temperature stability, remove fumes, and reduce heat loss, improving product quality and energy efficiency.

Ductwork: Optimized airflow systems ensure uniform temperatures across different heating methods and applications, minimizing product defects.

Safety Features: Purge cycles eliminate flammable vapors, particularly crucial for gas ovens to prevent explosions, following NFPA and OSHA standards.

Control Systems: Modern ovens incorporate flame sensors, automatic shutoffs, and digital interfaces for precise temperature management and remote monitoring.

Heating Elements: Options include direct-fired burners, indirect heat exchangers, or electric resistors, each suited to specific safety and emission requirements.

Additional Features: Programmable controls, insulation types, chamber sizes, and loading mechanisms can be customized to enhance performance and reduce costs.

This component knowledge enables informed comparisons and optimal oven selection for specific industrial needs.