Introduction

This article offers a comprehensive overview.

Continue reading to explore key questions such as:

- What constitutes a calibration service?

- The concept of measurement traceability

- The significance of calibration

- How calibration services are conducted

- Different types of calibrators

- Varieties of calibration services

- How to interpret calibration reports

- And additional insights...

Chapter 1: Understanding Calibration Services

Calibration services specialize in identifying inaccuracies and uncertainties in measurement instruments. During calibration, the device under test (DUT) is carefully compared against a certified reference standard to measure its deviation from ideal values. This deviation is known as error. once identified, the DUT can be adjusted to improve its accuracy. However, this correction process, which involves fine-tuning the device, is performed separately.

Calibration must be conducted as a formal procedure in a certified laboratory environment. Some providers offer on-site calibration services, allowing equipment to be calibrated at its point of use without disrupting operations.

After calibration, the service provider issues a detailed certificate to the client. This document includes instrument-specific results, crucial for documentation and traceability. A calibration label may also be attached to the equipment to indicate its calibrated status.

Chapter 2: What is Measurement Traceability?

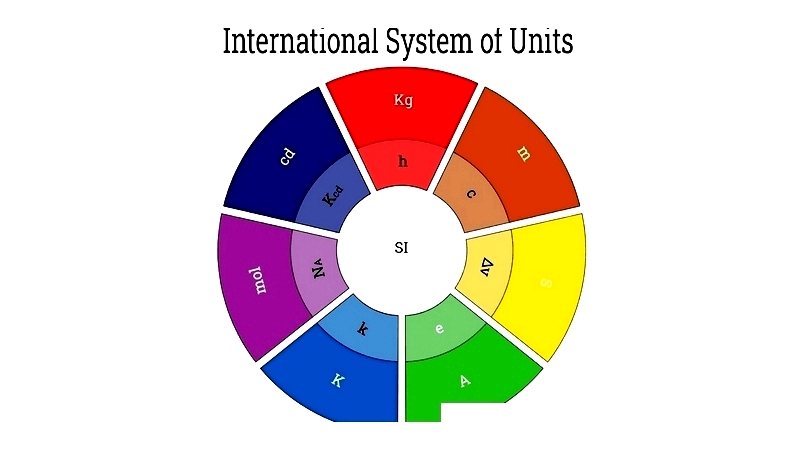

International System of Units (SI) and Its Role in Metrology

The International System of Units (SI) is a globally standardized measurement system. Derived from the French "Système International d'Unités," it's commonly called the metric system. Designed for precision, SI units enable universal expression and comparison of physical quantities, facilitating clear communication across fields. Standardized measurement forms the foundation for science, engineering, manufacturing, pharmaceuticals, and quality assurance processes.

Established in 1960 by the 11th General Conference on Weights and Measures (CGPM), the SI system is maintained by the Bureau International des Poids et Mesures (BIPM) in Paris. This organization ensures global measurement uniformity in physical measurements, regulatory compliance, and calibration services.

The SI system includes seven base units that form all derived units, covering fundamental measurements like length, mass, and time. For instance, one meter is defined by the distance light travels in a vacuum in 1/299,792,458 seconds. These definitions use natural constants for reproducibility. The base units are regularly updated based on advancements in metrology. Combining these base quantities creates 22 derived units. The table below lists the base quantities and their units:

SI prefixes like kilo-, milli-, and micro- modify base units to represent different scales, simplifying unit conversion. This system supports various applications, from instrument calibration to quality control.

Metrological Traceability: Ensuring Measurement Reliability

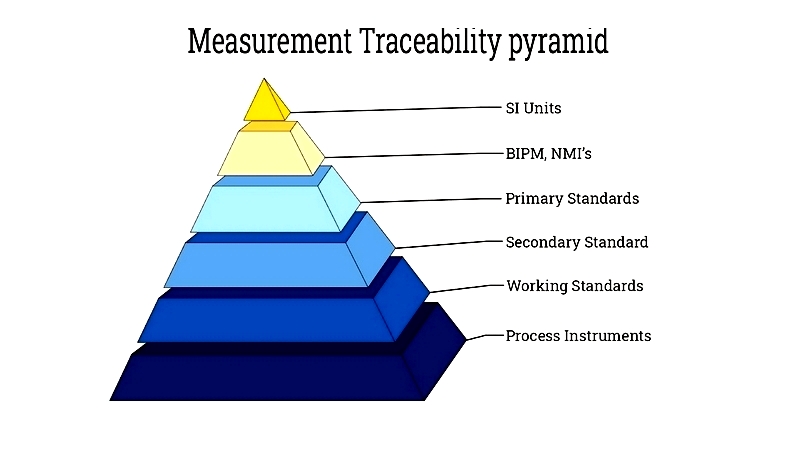

Metrological traceability, or measurement traceability, is crucial for quality assurance in science and industry. According to metrology standards, traceability links measurement results to references through a documented chain of calibrations, each with stated uncertainties. This ensures compliance with international measurement standards and quality guidelines. Traceability is mandatory for ISO/IEC 17025 accredited laboratories and facilities following GMP/GLP standards.

The measurement traceability pyramid illustrates this concept:

The traceability chain begins with working standards used on devices under test. These instruments must be calibrated by accredited labs against secondary standards, ultimately tracing back to National Metrology Institutes (NMIs) like NIST. NMIs maintain primary standards, the highest references for global measurements.

SI units form the pyramid's foundation. Each calibration level reports its measurement uncertainty, ensuring transparency. As traceability moves from primary to working standards, uncertainty increases slightly, highlighting the need for regular calibration.

Traceability is vital for compliance and risk management in industries like aerospace and pharmaceuticals. Traceable measurements validate product claims and facilitate international trade by aligning with recognized standards.

For traceability, three criteria must be met:

- Equipment must undergo regular calibration by qualified providers. Calibration results have limited validity periods.

- A documented trail must exist, including calibration certificates with reference standards, results, and lab accreditation.

- Each calibration must include uncertainty estimation, essential for quality control and compliance.

Note: In the U.S., NIST serves as the national metrology institute, providing traceable calibration services and reference materials.

When choosing a calibration provider, select accredited labs with NIST-traceable capabilities. Verify their accreditation scope, measurement uncertainties, and support policies to meet your industry requirements.