Introduction

This article covers everything you need to know about inkjet printers and their applications.

You will learn about:

- What an Inkjet Printer is

- Different types of Inkjet Printers

- The manufacturing process of Inkjet Printers

- Common uses for Inkjet Printers

- And much more...

Chapter 1: What is an Inkjet Printer?

An inkjet printer is a printing device that sprays tiny ink droplets onto various surfaces to create text, images, and codes. These printers mark essential information like expiration dates, serial numbers, and barcodes on materials including paper, plastic, metal, and glass. The technology works by ejecting precise ink droplets through nozzles onto the target surface.

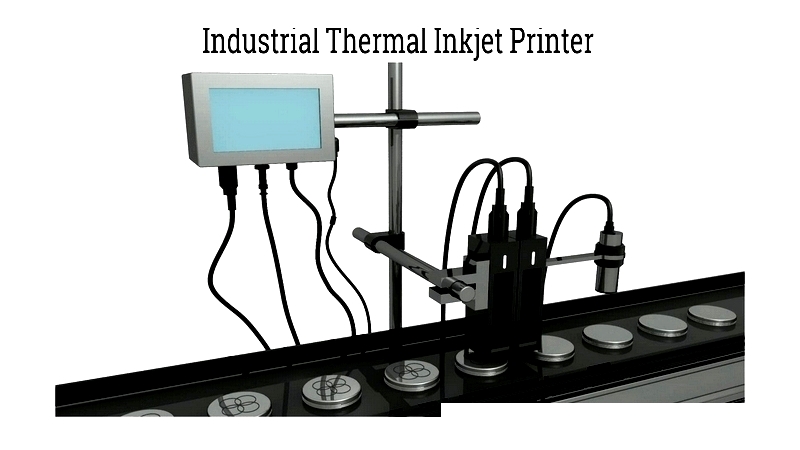

In industrial settings, continuous inkjet printers release streams of ink particles to label products on manufacturing lines. Each item requires identification for storage and distribution. These printers automate the labeling process as products move through the system, efficiently imprinting necessary details.

Chapter 2: Types of Inkjet Printers

Inkjet printers serve vital roles in both domestic and industrial applications, providing solutions for document printing and product marking. Home and office printers handle reports, presentations, and forms, while industrial models manage product coding and traceability.

Industrial inkjet printers fall into two main categories: continuous inkjet (CIJ) and drop-on-demand (DOD) systems. CIJ printers excel in high-speed environments, while DOD printers offer precision printing with thermal and piezo variants.

Continuous Inkjet (CIJ) Printers

CIJ printers are robust industrial solutions for high-volume marking. They print numerals, logos, and barcodes without contact, maintaining quality on uneven surfaces. The printing process involves creating charged ink droplets that form patterns on products.

These printers support various ink types and operate continuously with minimal maintenance, making them ideal for food, pharmaceutical, and consumer goods industries.

Drop-On-Demand (DOD) Inkjet Printers

DOD printers release ink only when needed, conserving ink while delivering high-resolution prints. They handle complex graphics and variable data for packaging and product marking applications.

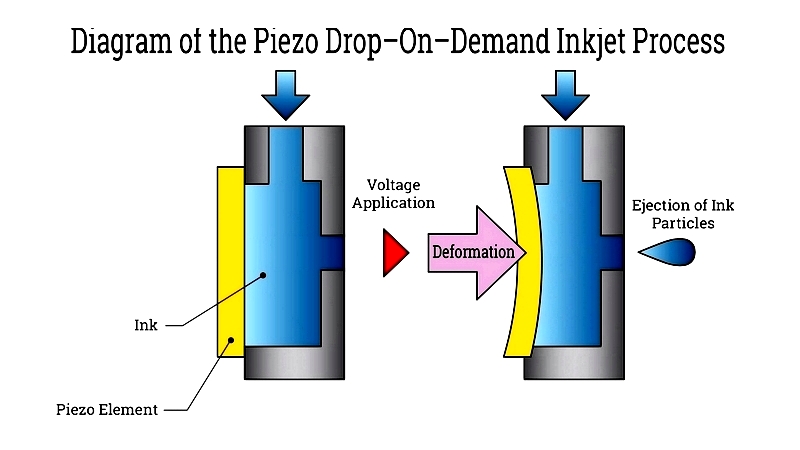

Piezo Drop-On-Demand Inkjet Printing

Piezo DOD printers use piezoelectric crystals to control ink droplets precisely. This technology supports various specialty inks and produces high-quality images for industrial and commercial uses.

- Bend Mode – Uses electromechanical transducers for precise droplet control in high-fidelity printing.

- Shear Mode – Applies electric fields for rapid printing in textile and industrial applications.

Piezo technology offers reliability and excellent print quality for advanced digital printing needs.

Thermal Drop-On-Demand Inkjet Printing (TIJ)

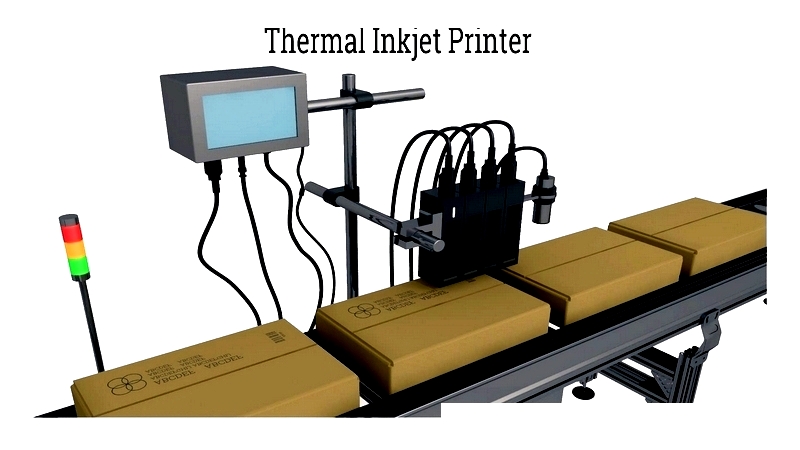

TIJ printers heat ink to create vapor bubbles that eject droplets. Common in desktop printers, they're also used for product labeling in retail and pharmaceutical industries.

These printers offer precise printing with fast production cycles and support various media types. Their affordability and ease of use make them popular for batch numbering and regulatory markings.

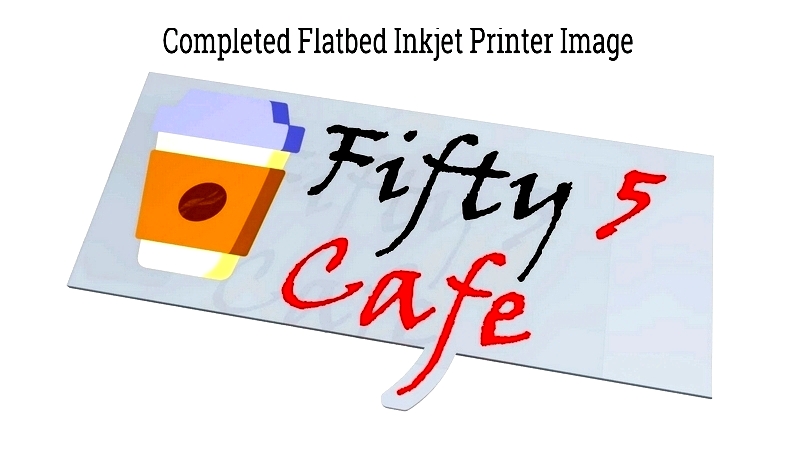

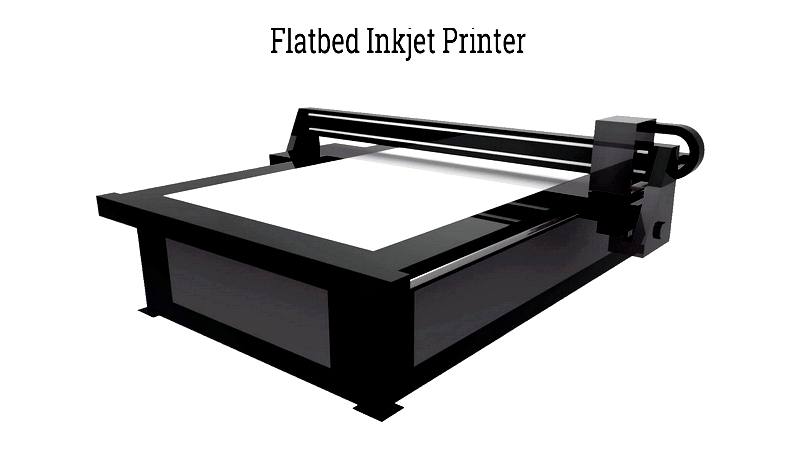

Flatbed Inkjet Printer

Flatbed printers handle large-format printing on rigid materials like wood, metal, and glass. They use UV-cured inks for durable, high-quality prints suitable for signage and displays.

The Flatbed Inkjet Printing Process

The process involves:

- Image Preparation – Creating digital files for printing.

- Material Loading – Positioning substrates on the printer bed.

- Printing – Applying ink precisely according to digital files.

- Curing – Using UV lamps to harden ink instantly.

Advantages of Flatbed Inkjet Printing

Key benefits include:

- Versatility in printing on various materials

- High image quality and production speed

- Cost efficiency and environmental benefits

Single Pass Inkjet Printers

Single pass printers offer ultra-high-speed printing for industrial applications. They feature multiple printheads for continuous, high-resolution output on packaging and textiles.

The diverse range of inkjet printers—from CIJ to single pass systems—provides solutions for every printing need, whether for mass production or specialized applications.