Introduction

This article provides an in-depth exploration of AGV forklifts and their applications.

You will learn about key topics including:

- What is an AGV Forklift

- Types of AGV Forklift Guidance Systems

- Types of AGV Forklifts

- Applications of AGV Forklifts

- And much more...

Chapter One – What is an AGV Forklift?

An AGV forklift is an autonomous robotic machine that operates without a driver, capable of transporting, lifting, retrieving, and positioning loads between locations. Controlled by an advanced computer system, these automated guided vehicles (AGVs) combine computer programming and robotics within a sophisticated technical framework.

AGV forklifts can handle various load sizes and shapes, performing pickups and deliveries from both floor level and elevated surfaces like conveyor belts and storage racks. Available in counterbalance and outrigger configurations, they can manage loads up to and exceeding 10,000 lbs. Different guidance technologies are employed in AGV forklifts, including laser-guided systems, magnetic tape, natural navigation, and magnetic markers. Selecting the appropriate navigation system is crucial for optimal AGV forklift performance, tailored to specific operational requirements.

Chapter Two – Types of AGV Forklift Navigation Systems

Automated Guided Vehicle (AGV) forklifts are advanced robotic transporters designed to autonomously move loads in warehouses, distribution centers, and manufacturing facilities. Using sophisticated navigation systems, these self-driving forklifts execute programmed movements to ensure precise, repeatable material handling. While appearing to navigate independently, every movement is controlled by specialized AGV navigation technology that ensures safety, efficiency, and route accuracy. Understanding different navigation systems is essential for businesses evaluating AGV forklift solutions to enhance logistics automation, operational efficiency, and workplace safety.

Modern AGV forklift navigation technologies employ various intelligent solutions, from magnetic guidance to laser-based and vision-driven mapping approaches. Choosing the right system is critical for optimal performance in applications like pallet transport, order picking, stock replenishment, and just-in-time delivery. Contemporary navigation systems for autonomous forklifts ensure route adherence, obstacle avoidance, and compliance with safety regulations while maximizing uptime and reducing labor costs in automated material handling environments.

AGV Forklift Navigation Systems

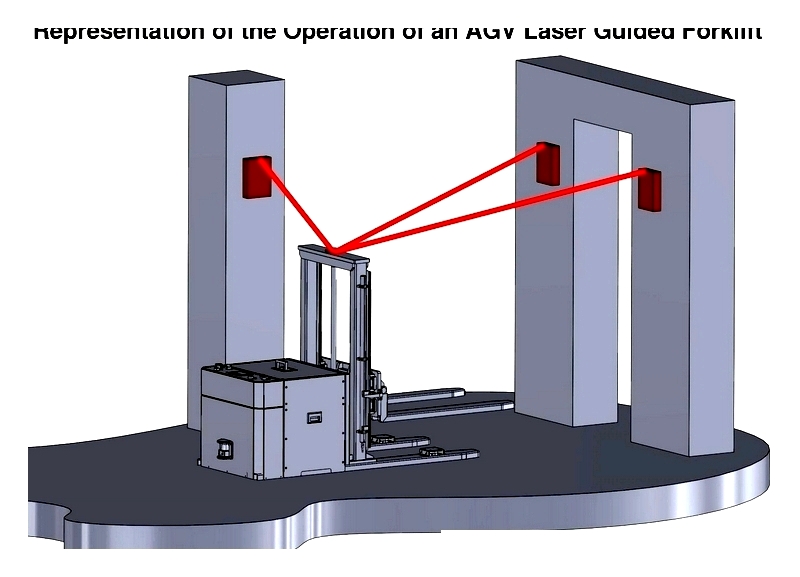

Laser Guided (LGV) Navigation

The Laser Guided Vehicle (LGV) navigation system is one of the most advanced and widely used solutions for AGV forklift automation. It uses a navigation laser mounted on the forklift that interacts with reflective targets installed throughout the facility. The laser scanner emits rotating beams to continuously detect these reference points, while intelligent sensors process the data to calculate and adjust the AGV's position multiple times per second. This ensures precise path following and obstacle avoidance, making LGV systems ideal for high-density warehouses and dynamic production environments.

Laser-guided navigation offers advantages including quick installation, flexible route programming, and layout adaptability. Since this system doesn't require floor modifications, deployment and rerouting are cost-effective and minimally disruptive. LGV systems can integrate with warehouse management systems (WMS) for seamless logistics automation and real-time inventory tracking. For businesses seeking advanced AGV forklift navigation, laser guidance provides superior accuracy and flexibility.

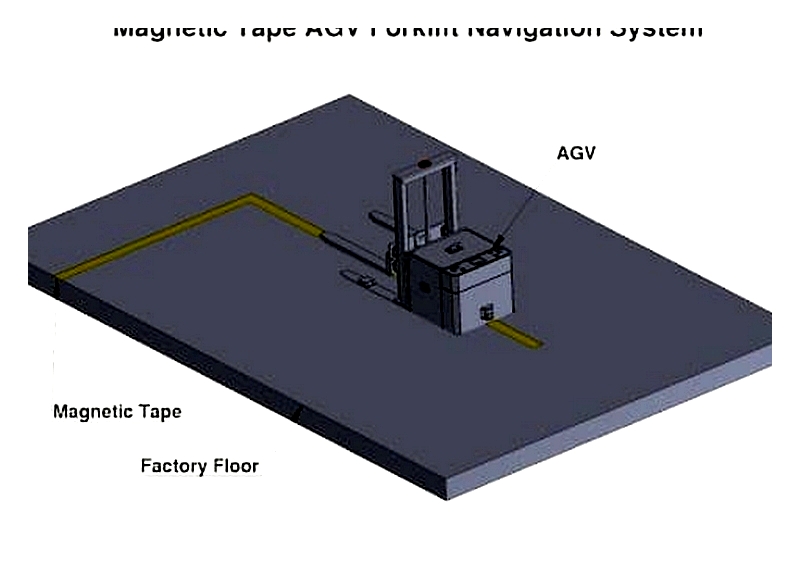

Magnetic Tape

Magnetic tape guidance remains a cost-effective navigation method for AGV forklifts, particularly in fixed-path applications. In this system, magnetic tape is affixed to the floor along predetermined paths. AGV forklifts use magnetic sensors to detect and follow the tape with consistent accuracy. RFID tags at intersections enable automated decision-making for turning, stopping, or load transfer operations.

While simple to install and maintain, magnetic tape navigation limits AGV forklifts to fixed routes, reducing operational flexibility. Layout changes require physical tape repositioning. However, this method provides excellent positional accuracy and requires no facility modifications, making it suitable for repetitive transport lanes and point-to-point logistics.

Natural Navigation Systems (Vision and SLAM)

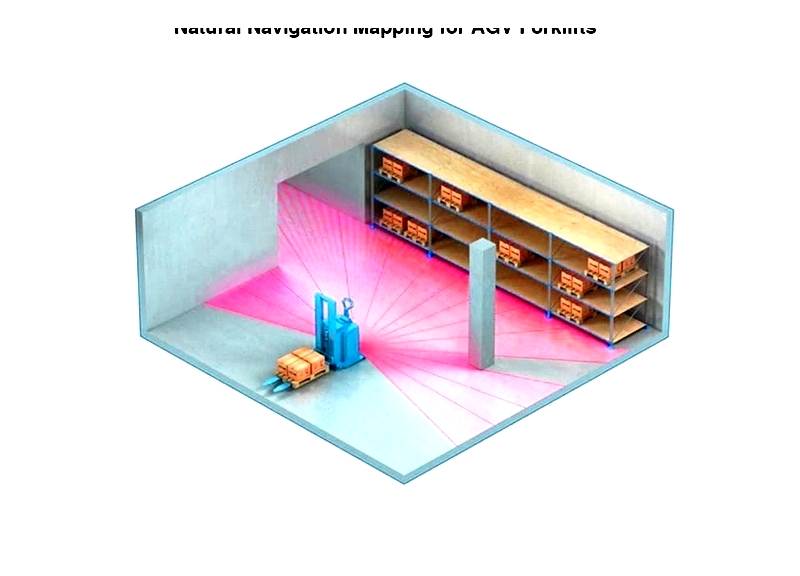

Natural navigation represents cutting-edge AGV technology, enabling dynamic path planning in changing environments. Using Simultaneous Localization and Mapping (SLAM), AGV forklifts create and update digital maps while determining their position. This system combines vision cameras, lidar scanners, and 3D sensors processed by onboard computers and algorithms.

After initial mapping, AGV forklifts continuously compare real-time sensor data with stored maps to ensure accurate localization and safe navigation in dynamic areas. This capability facilitates integration with automated storage systems and warehouse automation platforms. Natural navigation AGVs are ideal for facilities prioritizing scalability and Industry 4.0 integration.

Magnetic Spots

Magnetic spot guidance provides high-precision navigation for AGV forklifts. Magnetic cylinders embedded in the floor serve as reference points, with AGVs moving sequentially between spots while maintaining precise positioning. This system offers exceptional accuracy, minimal maintenance, and reliable route control, making it suitable for high-value inventory areas and precision applications.

Wire Guided Technology

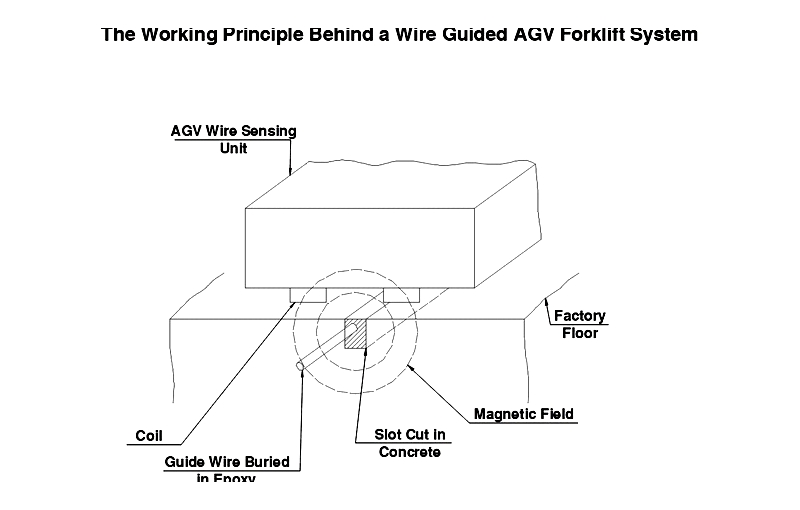

Wire-guided navigation is a robust solution for AGV forklifts in fixed-path industrial settings. A conductive wire installed in the floor emits a radio frequency signal detected by the AGV's antennas, enabling precise path following. While highly reliable, this system offers limited flexibility as pathway changes require floor modifications. Wire guidance remains a proven choice for heavy manufacturing and high-accuracy applications.

Choosing the Right AGV Forklift Navigation System

Selecting the optimal AGV forklift navigation system requires evaluating:

- Facility Environment: Layout stability and space constraints

- Precision Requirements: Load handling and docking tolerances

- Installation Impact: Facility modification requirements

- System Integration: Compatibility with WMS and ERP systems

- Budget Considerations: Initial investment and long-term costs

- Operational Flexibility: Need for route reconfiguration

By matching navigation technology with operational needs, businesses can implement AGV forklift solutions that maximize productivity, safety, and return on investment.