Introduction

This article provides an in-depth exploration of DC-DC power supplies.

Key topics covered include:

- Working principles of DC-DC power supplies

- Different types of DC-DC power supplies

- Applications and advantages of DC-DC power supplies

- Additional relevant information

Chapter 1: Understanding DC-DC Power Supplies

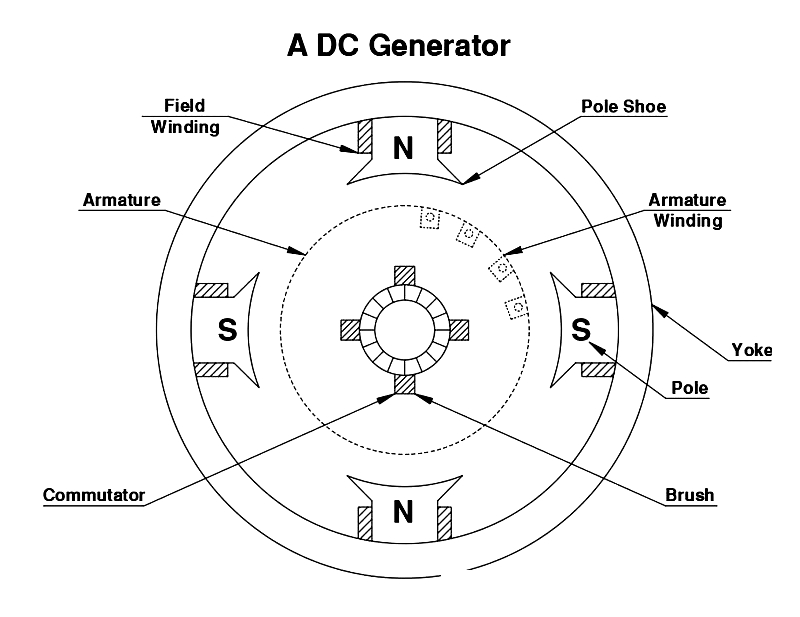

This section introduces fundamental concepts of DC-DC power supplies, focusing on their design, construction, and basic operating principles.

DC-DC Power Supply Fundamentals

A DC-DC power supply converts electrical power from one voltage and current specification to another, enabling efficient voltage transformation with minimal energy loss.

Similar to transformers but for direct current, DC-DC converters adjust voltage levels while maintaining impedance. These devices don't generate power but transform input energy, with modern units achieving up to 90% efficiency. They accommodate various voltages, from small batteries to power transmission systems.

Key Concepts in DC-DC Power Supplies

Modern integrated circuits allow higher switching frequencies, enabling smaller magnetic components and faster response times. Wide bandgap semiconductors like SiC and GaN further enhance performance with lower losses.

Common converter types include:

- Buck converters (step-down)

- Boost converters (step-up)

- Buck-boost converters (adjustable output)

- Flyback converters (isolated designs)

Selection depends on application requirements balancing performance, size, and cost.

(Bipolar)

VF

Coil Selection Guidelines

Refer to inductance charts based on frequency and load current. Lower DC resistance improves performance, while proper current ratings prevent overheating and saturation.

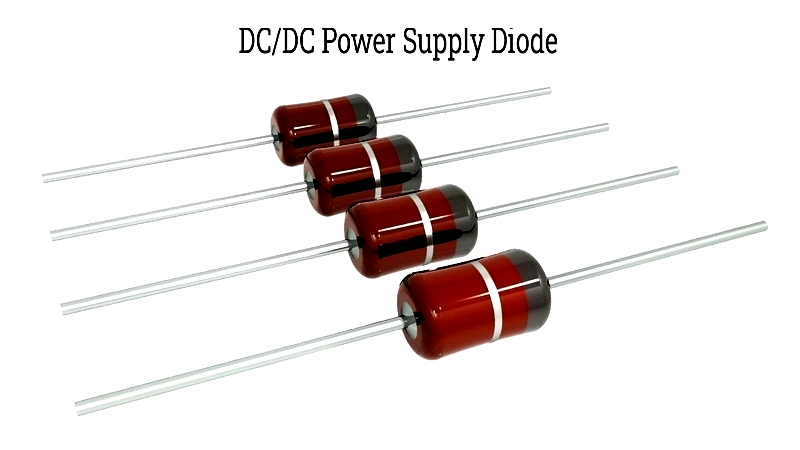

Diode Selection

Choose diodes with low forward voltage (under 0.6V) and minimal capacitance to reduce losses and noise. Current ratings should exceed peak coil currents.

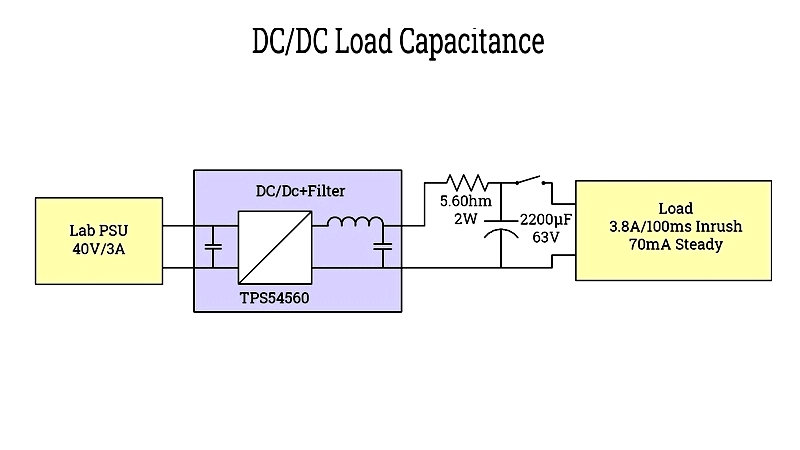

Load Capacitance

Consider temperature effects on ceramic capacitors. Tantalum capacitors (10-100µF) with proper ESR (0.1-0.5Ω) ensure stable operation.

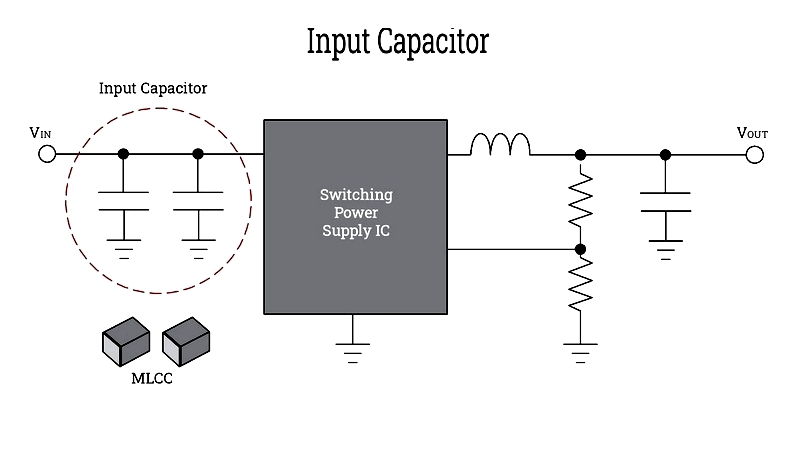

Input Capacitors

Place input capacitors close to ICs for effective ripple reduction. Low ESR types are recommended for step-down converters.

External Transistors

MOSFETs with low ON resistance are preferred, except for sub