Introduction

This article provides comprehensive details about zirconia ceramic and ZTA.

You'll explore various topics including:

- The fundamentals of Zirconia Ceramic and ZTA

- Different varieties of Zirconia Ceramics and ZTA

- Manufacturing processes for Zirconia Ceramics and ZTA

- Applications of Zirconia Ceramic and ZTA

- And much more...

Chapter One – Understanding Zirconia Ceramics and ZTA

Zirconia ceramics, commonly known as zirconium dioxide ceramics, are prized for their remarkable strength and durability. These materials exhibit exceptional hardness along with excellent wear and corrosion resistance, while overcoming the typical brittleness of conventional ceramics. Among various types, yttria- or magnesia-stabilized zirconia ceramics are most widely used.

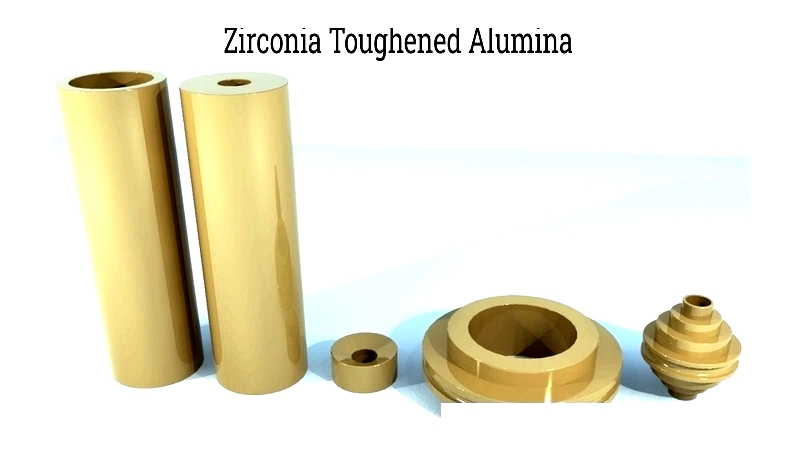

Zirconia Toughened Alumina (ZTA) is a composite ceramic formed by combining alumina with zirconia. In this structure, zirconia grains are uniformly distributed within an alumina matrix. ZTA demonstrates greater strength and toughness than pure alumina while remaining more cost-effective than pure zirconia.

The combination of aluminum oxide and zirconium oxide significantly enhances the material's toughness, strength, hardness, and wear resistance. This improvement primarily results from transformation toughening, a mechanism that substantially boosts the ceramic's fracture toughness. Under stress, zirconia particles undergo crystal structure changes that cause volume expansion, effectively sealing any developing cracks.

Chapter Two – Varieties of Zirconia Ceramics and ZTA Ceramics

Zirconia ceramics, or zirconium oxide ceramics, have undergone significant advancements to satisfy modern high-performance requirements across medical, automotive, semiconductor, and manufacturing sectors. Through careful modification of crystal phases and compositions, engineers have developed multiple advanced zirconia ceramic forms with enhanced mechanical properties, superior toughness, and improved wear and corrosion resistance. Zirconia-toughened alumina (ZTA) represents one such innovation, merging the benefits of zirconia and alumina ceramics to achieve exceptional versatility and performance characteristics demanded by various industries.

Manufacturers incorporate different stabilizing oxides—including yttrium oxide, cerium oxide, magnesium oxide, and aluminum oxide—to improve zirconia ceramic stability and durability. The choice of stabilizer directly influences key properties such as fracture toughness, thermal stability, electrical conductivity, and resistance to corrosion and chemical attack. By fine-tuning formulations and processing techniques, manufacturers can create specialized ceramics optimized for specific environments and challenging operational conditions.

Zirconia Ceramic Types

Ceria Stabilized Zirconia (CSZ)

Ceria stabilized zirconia (CSZ) demonstrates remarkable toughness, excellent mechanical strength, and long-term durability, especially in moist environments where low temperature degradation (LTD) is a concern. With outstanding flexural and compressive strength, CSZ is widely used for manufacturing precision sensors, instrumentation components, analytical devices, industrial probes, high-performance pumps, fluid handling systems, and advanced valve parts.

CSZ's unique microstructure provides exceptional resistance to hydrothermal aging and water-induced damage, ensuring superior performance in harsh or corrosive conditions. Its high-temperature stability makes it valuable for applications where conventional ceramics deteriorate over time. These characteristics make CSZ particularly suitable for energy sector components, laboratory equipment, and processing systems.

The advanced ceramics field continues to evolve, with ongoing research focused on enhancing zirconia properties through innovative stabilizers and composite materials. This ensures zirconia remains a leading solution for critical industrial applications.

Fully Stabilized Zirconia Ceramics (FSZ)

Fully stabilized zirconia (FSZ) primarily uses yttrium oxide (Y₂O₃) as a stabilizer, imparting exceptional thermal and structural stability to the zirconia matrix. FSZ excels in applications requiring superior thermal shock resistance, high fracture toughness, excellent corrosion resistance, and minimal ionic conductivity. Its selective oxygen ion permeability makes it indispensable for oxygen sensors, solid oxide fuel cells (SOFCs), and membrane technologies—critical components in automotive emission control, environmental monitoring, and clean energy systems.

While zirconia typically undergoes destructive volume expansion during phase transitions, yttrium oxide in FSZ maintains cubic phase stability, ensuring reliable performance across wide temperature ranges—even in demanding industrial environments like metal refining and glass manufacturing.

Partially Stabilized Zirconia (PSZ)

Partially stabilized zirconia (PSZ), recognizable by its light cream color, incorporates 10% magnesium oxide (MgO) as an effective stabilizer. PSZ maintains high mechanical strength, excellent fracture toughness, and outstanding chemical resistance even at extreme temperatures, making it ideal for harsh environments. Its fine-grained microstructure provides resilience against thermal and mechanical stresses while resisting aggressive chemicals common in chemical processing and refining operations.

PSZ's corrosion resistance in high-temperature fluid streams, including strong acids and concentrated alkalis, makes it particularly valuable. Its chemical inertness and high compressive/tensile strengths ensure long service life in demanding industrial applications. Notably, PSZ can be precision-machined into complex shapes for specialized components.

Key applications include pump seals for caustic chemicals and high-performance roller bearings in heavy manufacturing equipment. Additional uses encompass furnace linings, jet nozzle inserts, foundry pins, and crucibles.

Tetragonal Zirconia Polycrystal (TZP)

Tetragonal zirconia polycrystal (TZP) ceramics are renowned for their exceptional fracture toughness, high flexural strength, and superior hardness at room temperature, along with excellent high-temperature corrosion and oxidation resistance. These properties make TZP highly desirable for medical devices, particularly artificial hip joints, dental crowns, bridges, and root posts.

In industrial settings, TZP serves as an effective thermal barrier coating for fuel rod claddings, aerospace turbine blades, and engine components subjected to rapid temperature changes and mechanical stress. Its thermal expansion compatibility with iron alloys makes TZP valuable for assemblies requiring strong bonding and dimensional stability across temperature ranges. This combination of toughness and strength earns TZP the nickname "ceramic steel" in industry circles.

Transformed Toughened Zirconia Ceramics (TTZ)

Transformed toughened zirconia ceramics (TTZ) uniquely emulate certain ductile characteristics of steel rather than exhibiting traditional ceramic brittleness. Through martensitic phase transformation, TTZ materials redistribute and absorb stresses at crack tips, delaying crack propagation and enhancing damage tolerance. This mechanism produces ceramics with outstanding crack resistance, reliability under stress, and extended service life in demanding environments.

A prime application is premium ceramic knives. TTZ knives, twice as hard as steel counterparts, feature ultra-sharp edges that maintain their cutting performance through repeated use. These properties make TTZ ideal for professional chefs, laboratory technicians, and industries requiring surgical precision. Other applications include aerospace structural components, manufacturing wear guides, and high-strength turbine parts.