Introduction

This article offers comprehensive information about palletizers. Continue reading to learn about:

- What palletizers are and how they function

- Their historical development

- Traditional palletizer systems

- Robotic palletizing solutions

- Hybrid palletizer models

- Additional relevant information

Image Provided by: TopTier

Image Provided by: TopTier

Chapter 1: What is a Palletizer and How Does It Work?

A palletizer is an automated system designed to arrange and stack products into organized unit loads, enhancing efficiency in handling, storage, and transportation. Typically integrated into broader packaging operations, it may incorporate functions like weighing, counting, sorting, labeling, metal detection, and wrapping. These processes can either be built into the palletizer or performed by separate equipment.

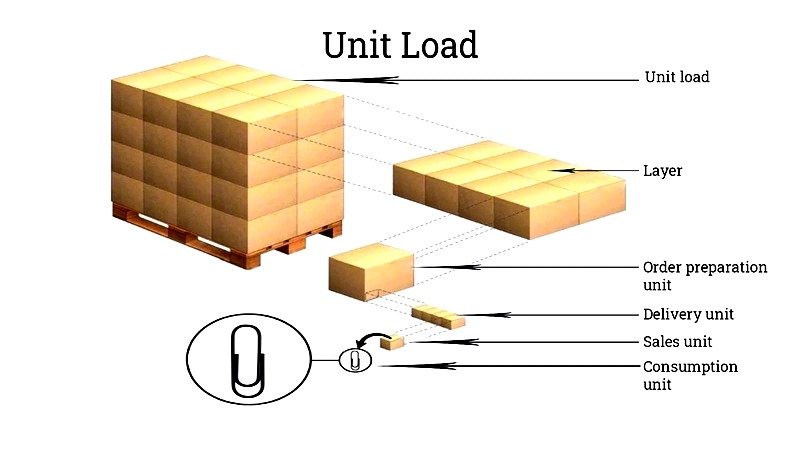

Palletizing creates unit loads by consolidating materials for more efficient movement. Transporting a single large unit proves faster and more cost-effective than handling multiple smaller items. Most finished goods are packaged in boxes, cases, trays, or crates before being assembled into complete loads supported by pallets or roll cages. These packaging formats constitute secondary unit loads, with roll cages classified as tertiary unit loads.

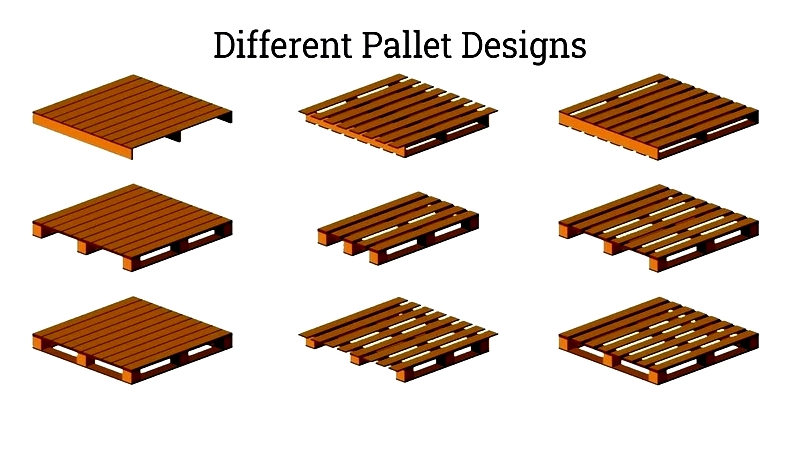

The palletizer organizes products onto pallets - flat, durable platforms made from wood, plastic, paper, or metal featuring notches or openings. These openings allow forklifts and pallet jacks to lift and move the load, determining whether the pallet is two-way or four-way accessible. Most pallets support loads up to one metric ton across approximately one square meter. Below are standard pallet dimensions.

(W x L) in millimeters

(W x L) in inches

(ISO Container)

Some palletizers can stack products using slip sheets or conveyor surfaces, known as unitizers. These unitized loads eliminate pallet requirements, making "palletizers" and "unitizers" sometimes interchangeable terms.

Types of Pallets

Pallets primarily come in three wood or plastic varieties, plus one cardboard type.

The most common is the GMA pallet, typically 40x48 inches with side notches for lift access.

CHEP pallets rank second in popularity. Also usually 40x48 inches, they feature blocks on all sides for multi-directional handling and are recognizable by their blue color.

PECO pallets are gaining traction, offering similar services to CHEP with distinctive red markings.

Pull Boards consist of corrugated sheets with dual 3-inch tabs on adjacent sides. Special forklift attachments use these tabs for load movement. Preferred for hygiene and space efficiency, they allow approximately 5 extra inches per load, potentially saving significant transportation costs.

Some palletizers can stack items on slip sheets or conveying surfaces (unitizers), eliminating pallet needs. In certain contexts, "palletizers" and "unitizers" are synonymous.

Different companies require various pallet configurations to meet specific needs.

- Tier sheets or unconventional patterns may stabilize loads during manual transport to stretch wrappers.

- Automated systems enable smoother pallet movement, allowing pattern simplification for better pallet utilization.

- Improved pallet utilization generates substantial supply chain savings in transportation and warehousing.

- Simplified palletizing methods help customers achieve higher speeds and operational efficiency.

Pallet Patterns

This stacking method strengthens load integrity through foundational column support. Warehouses can stack pallets up to four units high, utilizing vertical box corner alignment for stability. The interlocked top section provides additional security, allowing safe forklift transport to wrapping stations.

Chapter 2: What is the history of palletizers?

Before automated palletizing systems, warehouses relied on manual stacking to organize products for storage and shipping. This labor-intensive process yielded low throughput. As global commerce expanded, efficient material handling solutions became essential. Pallets and handling equipment revolutionized logistics in the early 20th century, particularly during World War II for military supply chains.

Lamson Corp.'s 1948 mechanical palletizer marked a warehouse automation milestone. This row-forming system automated product arrangement into layers, significantly improving throughput and consistency compared to manual operations.

The 1970s introduced in-line palletizers with continuous product flow technology, enhancing efficiency in food/beverage, consumer goods, and manufacturing industries where rapid automation was crucial.

1980s robotic palletizers brought advanced automation with articulating arms and specialized tooling for diverse product handling. These systems offered flexibility, quick changeovers, and precise stacking for variable production environments.

Modern palletizers incorporate smart sensors, machine learning, and cloud-based management for real-time tracking and predictive maintenance. As e-commerce and global trade grow, advanced palletizing systems become increasingly vital for cost reduction and competitive supply chain operations.