Introduction

This article provides an in-depth exploration of industrial coatings, covering essential topics including:

- Principles of Industrial Coatings

- Industrial Coating Techniques

- Types of Industrial Coatings

- Applications and Benefits of Industrial Coatings

- And more…

Chapter 1: What Defines the Principle of Industrial Coatings?

This chapter examines the fundamental principles of industrial coatings and their diverse applications.

Understanding Industrial Coatings

Industrial coatings serve as protective layers applied to surfaces, shielding them from damage while improving appearance. Their primary purpose is to defend against environmental threats and other potential harm. These coatings can be applied to various surfaces, including concrete, wood, metal, plastic, glass, rubber, leather, mortar, and asbestos.

Available in numerous types, each industrial coating offers unique characteristics and benefits. Selecting the right coating depends on environmental conditions and surface properties. Manufacturers provide expert guidance on optimal application practices.

Designed for both aesthetics and durability, industrial coatings include options like Xylan dry film lubricants, resins, and xylene.

The Role of Industrial Coatings

Industrial coatings offer broad protection, primarily preventing equipment corrosion while enhancing visual appeal for specific applications. They're commonly used to protect materials such as concrete and steel.

Additionally, these coatings improve fire resistance and protect against other hazards. They're employed in water tanks and reservoirs to ensure safe drinking water and prevent corrosion.

Polymers like epoxy, moisture-cure urethane, polyurethane, and fluoropolymer are the most common industrial coating materials.

Key Factors in the Industrial Coating Process

Several critical elements influence industrial coating application:

Surface Preparation of the Substrate

Proper substrate cleaning ensures adhesion. Coatings typically bond mechanically or physically to surfaces, with chemical bonding also possible. Contaminants like dust or chemicals can cause premature coating failure.

Effective surface preparation is essential. Before application, surfaces must be cleaned of moisture, dry contaminants, and salts using methods like heating, blasting, or chemical cleaning. This prevents issues such as fisheyes, blistering, and adhesion failure.

Selecting the Appropriate Coating System

Priming enhances coating and sealant adhesion, ensuring long-term performance. Primers improve substrate-coating compatibility and create smoother surfaces.

After priming, various coating methods—including dip, brush, roll, spray, spin, and flow coating—can be used depending on substrate size and complexity.

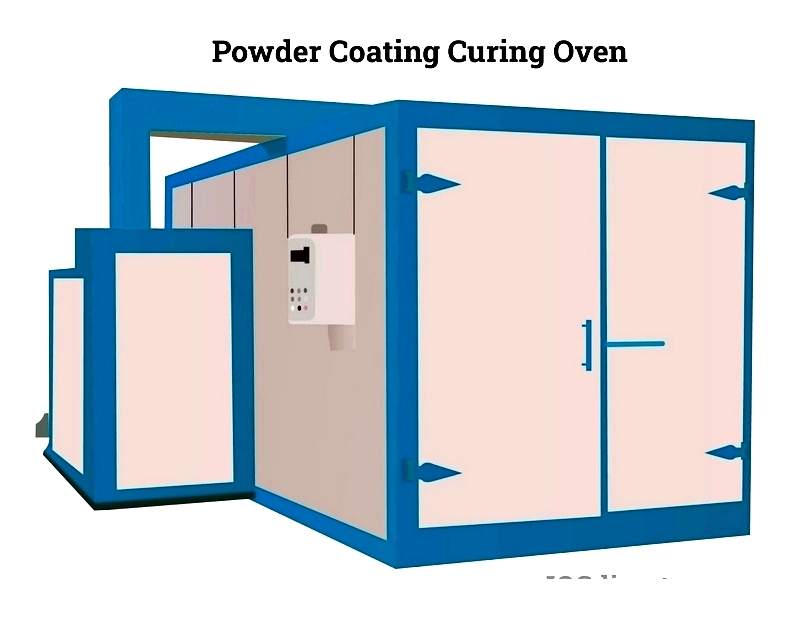

Curing and Drying Industrial Coatings

Proper curing and drying affect coating performance. Each product includes specific instructions for optimal results.

Curing requires maintaining correct substrate temperature for specified durations, with bake times varying by part thickness.

Inspection of Coated Parts

Finished parts must meet thickness standards for complete coverage. Effective inspection ensures coatings remain within required thickness ranges.

Choosing suitable coatings involves evaluating both equipment and materials. Proper maintenance of components like pump seals and filters is crucial for optimal results.

Suppliers collaborate with customers to assess procedures and maintain clean workspaces.

Factors When Creating Custom Industrial Coating Solutions

Consider these aspects for custom solutions:

Identifying the Substrate

Formulation depends on substrate materials like urethane, acrylic, or epoxy. Production timing also influences material selection.

Primers or additives can improve binding for specific substrate-coating combinations. Requirements like corrosion resistance or food safety compliance guide material choices.

Different substrates require specific application steps. For example, plastics may need heat curing to prevent deformation.

Environmental Considerations in Application

Environmental conditions affect coating selection. Controlled temperature and humidity ensure even finishes, while fluctuations may cause thermal shock.

Chemical exposure during application or drying can impact performance. Parts need protection from abrasion and UV during curing.

Process Definition

Application methods like spraying or dipping determine coating outcomes. Process planning includes substrate preparation, curing methods, and drying conditions.

Properties of Coatings

Industrial coatings exhibit distinct characteristics. While epoxy and urethane resist chemicals and physical stress, epoxies degrade outdoors. Water-based coatings may increase corrosion risk.

Key properties include flexibility, gloss retention, moisture resistance, and conductivity. Coating composition and application method determine functional and visual qualities.

Chapter 2: How Industrial Coating Techniques Work

Industrial coating techniques protect, enhance, and extend product lifespans across industries. Understanding these methods helps select optimal solutions for longevity, corrosion protection, and regulatory compliance in sectors like automotive, aerospace, and construction. Below are key application techniques:

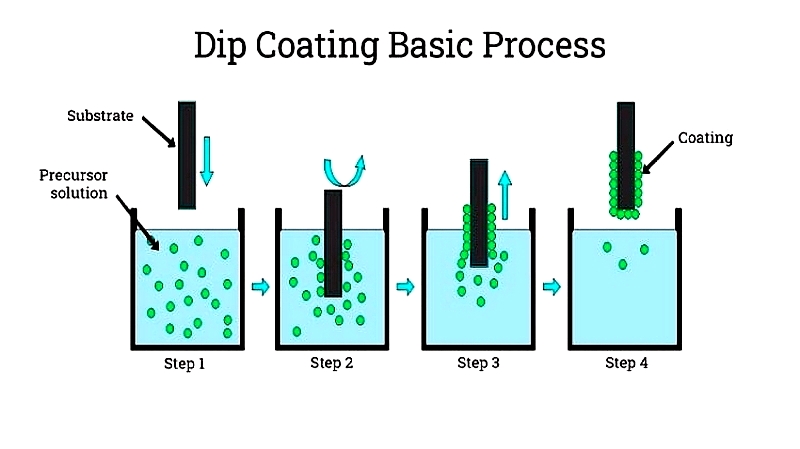

Dip Coating

This cost-effective process delivers uniform finishes on complex geometries, suitable for both mass production and custom jobs. Parts are immersed in liquid coating and withdrawn at controlled speeds, with thickness influenced by viscosity and withdrawal rate.

Surface cleaning ensures adhesion, while process control maintains quality. Dip coating protects against abrasion, moisture, and chemicals, offering functional and decorative benefits.

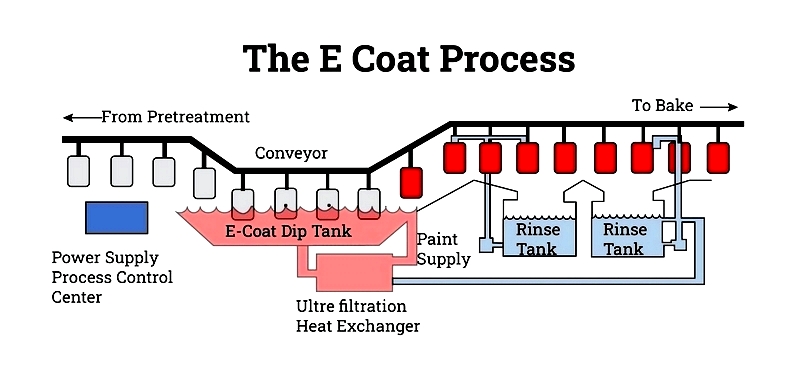

E-Coat (Electrophoretic Painting)

This hybrid technology combines electroplating and paint deposition. Parts submerged in charged paint emulsion receive uniform coverage when current is applied, ideal for complex shapes.

E-Coat provides superior corrosion resistance and appearance, outperforming powder coating in coverage consistency. It's widely used in automotive and aerospace industries.

Brushing

This manual method applies viscous coatings to hard-to-reach areas, suitable for touch-ups and repairs. Brush material compatibility is crucial for optimal results.

Roll Coating

Efficient for flat substrates, this technique uses rollers in manual or automated systems. It minimizes waste and ensures uniformity in automotive and construction applications.

Spraying

Versatile for various geometries, spraying accommodates viscous and low-viscosity coatings. Modern equipment reduces waste while ensuring quality finishes.