Introduction

This article covers everything about aluminum forgings, from their manufacturing process and applications to the types of aluminum alloys used.

You will learn:

- What Aluminum Forging Is

- Different Types of Aluminum Forging

- Applications of Aluminum Forgings

- Aluminum Alloys Used in Forging

- And more…

Chapter 1: What is Aluminum Forging?

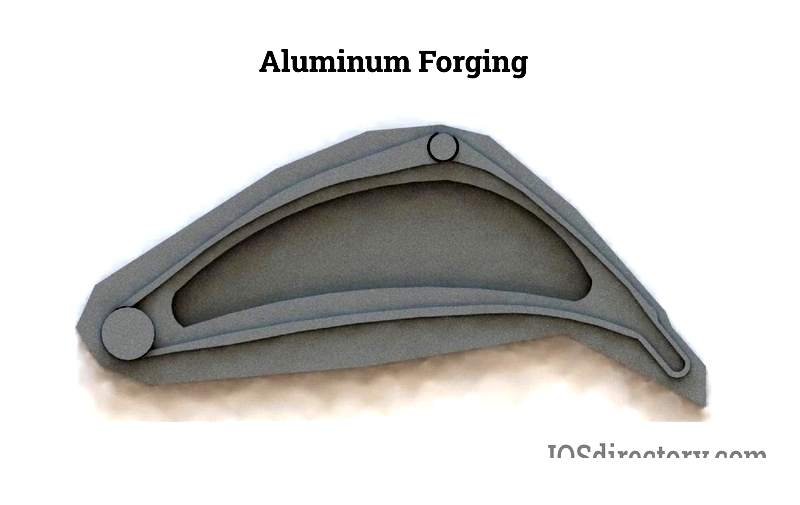

Aluminum forging is a manufacturing process that uses pressure and heat to shape aluminum alloys into strong, durable components. By pressing, pounding, or squeezing aluminum billets under high pressure, the process enhances the material's strength. The forging temperature can range from just below to slightly above the recrystallization point, or even at room temperature.

The process includes various techniques like open die, closed die, and rolled ring forging, chosen based on the product's design and intended use. Aluminum's lightweight, strength, durability, corrosion resistance, and forgeability make it ideal for numerous applications.

Compared to carbon steel, aluminum alloys exhibit lower deformation resistance at room temperature. Their deformation resistance is highly sensitive to temperature changes. While casting is common for shaping aluminum, forging offers additional benefits by refining the alloy's metallurgy through deformation energy. This process improves the material's internal structure, eliminates voids, and enhances durability.

Chapter 2: Types of Aluminum Forging

Choosing the right forging process is key to maximizing aluminum's potential. This lightweight, durable metal is widely used in automotive, aerospace, construction, marine, and electrical industries. Forging shapes aluminum into high-strength parts using compressive forces, with processes categorized as hot or cold forging based on temperature.

Advanced techniques include drop forging, press forging, upset forging, roll forging, rolled ring forging, isothermal forging, open die forging, and closed die forging. The choice depends on alloy type, design complexity, mechanical requirements, production volume, and application needs.

Cold Forging

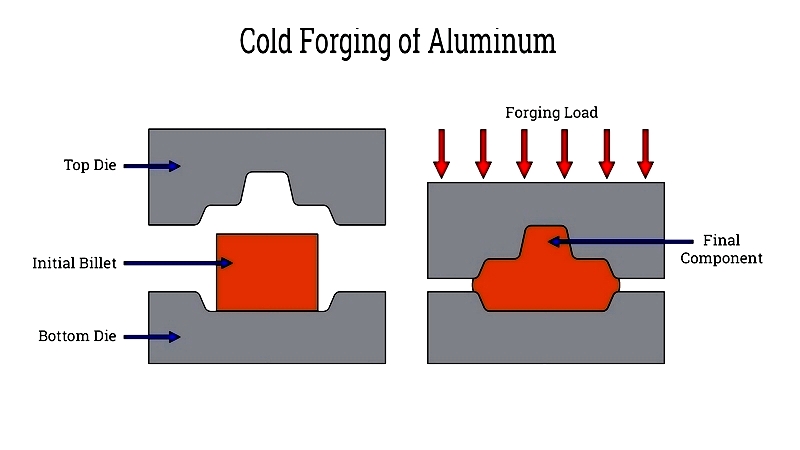

Cold forging shapes aluminum at room temperature, maintaining precision and surface finish. This energy-efficient method minimizes waste and is ideal for high-volume production of detailed components like automotive parts, electrical connectors, and aerospace fasteners.

Unlike machining, cold forging reduces material waste and post-processing. It achieves near-net shapes with features like holes, chamfers, and steps in a single operation, shortening production cycles while improving quality.

The process involves compressing aluminum billets between dies to achieve precise shapes. It's widely used in automotive, electronics, and consumer goods industries for its efficiency and repeatability.

Advantages of Cold Forging:

- High reproducibility for mass production

- Smooth surface finish, reducing secondary work

- Tight dimensional tolerances

- Customizable mechanical properties

- Lower energy costs (no pre-heating)

- Reduced material waste

- Enhanced fatigue resistance

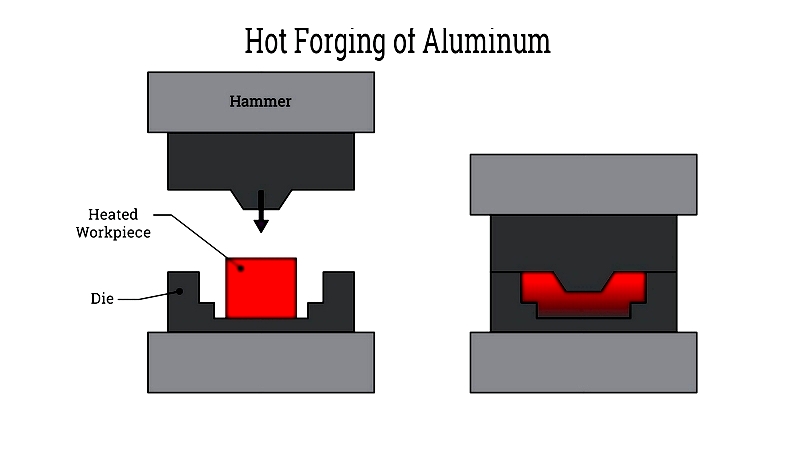

Hot Forging

Hot forging uses elevated temperatures (350–500°C) to improve aluminum's ductility and mechanical properties. This method is ideal for high-stress applications in aerospace, motorsport, and defense, producing parts with superior strength-to-weight ratios.

The process involves heating aluminum to its recrystallization temperature before shaping it with presses or hammers. This refines grain structure, enhancing durability and strength. Temperature control is critical to avoid defects and ensure uniform density.

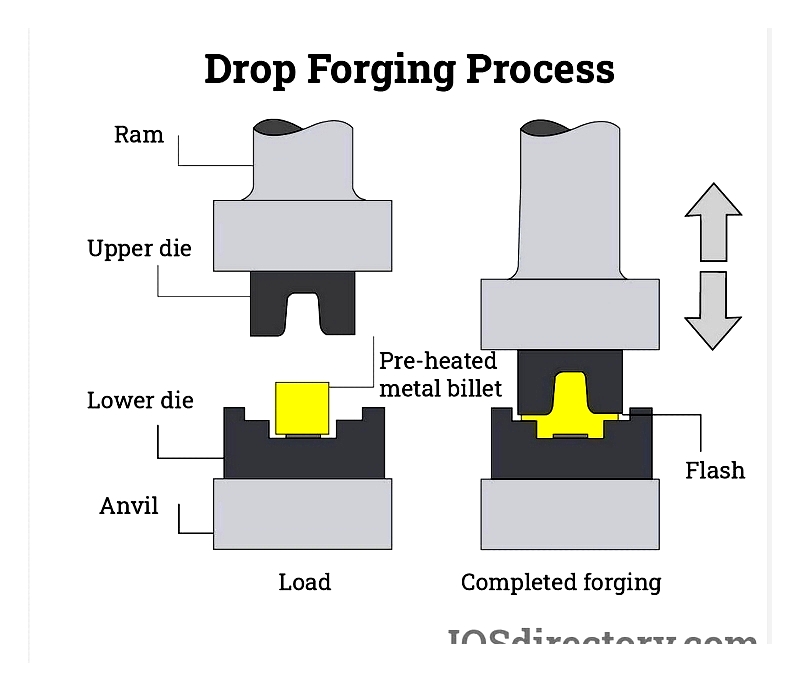

Drop Forging

Drop forging uses repeated hammer blows to shape heated aluminum between dies. This high-speed method is perfect for mass-producing strong, detailed components like automotive chassis parts and hardware. The process aligns grain structure with part geometry, improving strength and fatigue resistance.

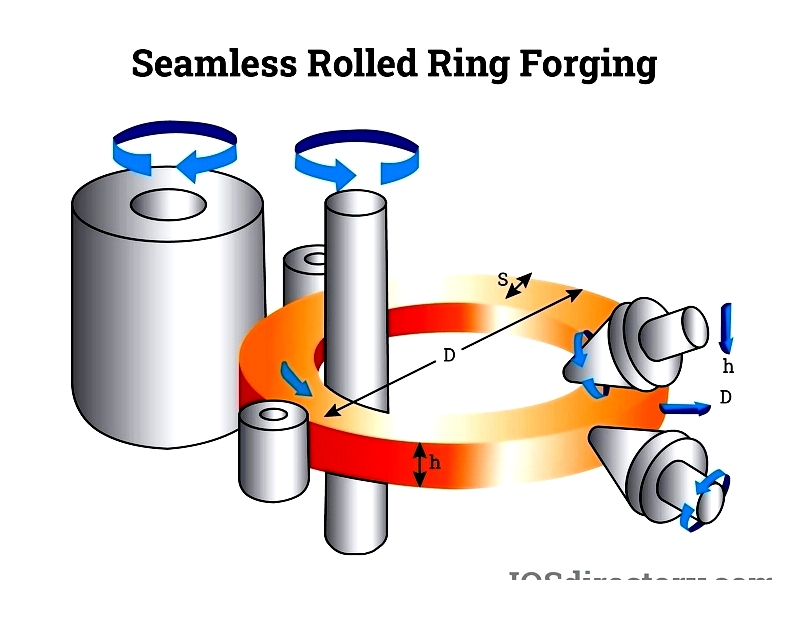

Rolled Ring Forging

Rolled ring forging creates seamless, high-integrity rings by expanding pierced billets on a mandrel. This open-die process enhances grain flow, producing rings with superior tensile strength and impact resistance. Applications include aerospace turbine rings and windmill components.

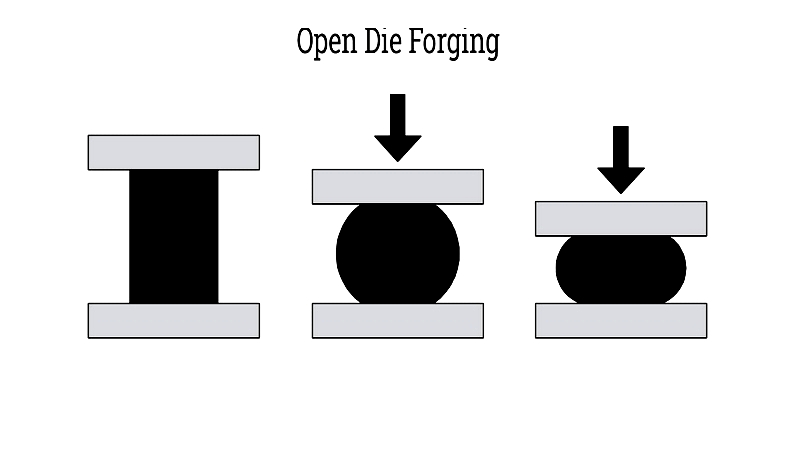

Open Die Forging

Open die forging shapes aluminum between simple dies, ideal for large, custom components like discs and shafts. The process improves toughness and fatigue resistance, making it suitable for heavy machinery and energy systems. It also serves as a pre-forming step for further processing.

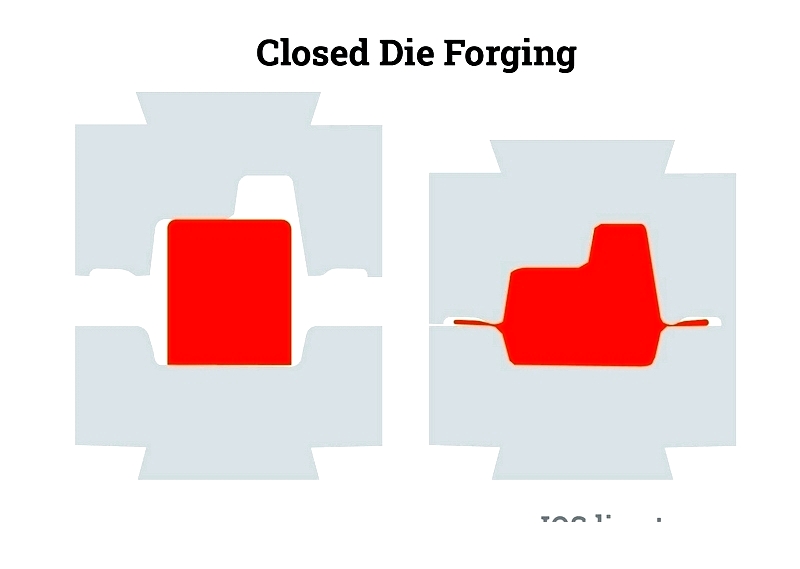

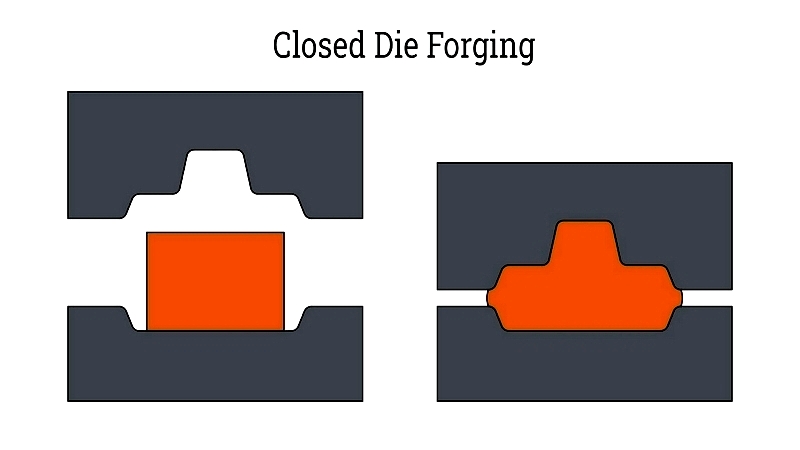

Closed Die Forging

Closed die forging uses precision dies to produce complex, high-tolerance parts. This method is ideal for aerospace and automotive applications, offering consistency and minimal post-processing. It enhances grain flow, improving strength and fatigue resistance in high-performance alloys like 6061 and 7075.