Introduction

This article provides an in-depth exploration of quartz glass. Continue reading to learn about:

- What quartz glass is

- How quartz glass is produced

- The properties of quartz glass

- Applications of quartz glass

- Handling quartz glass

- And more...

Chapter One – What is Quartz Glass?

Quartz is one of Earth's most abundant and widely distributed minerals, representing the only stable crystalline form of silica found on the Earth's surface. It occurs in various rock types, including igneous, metamorphic, and sedimentary formations. Through natural processes like weathering and erosion, quartz accumulates in soils, water bodies, and sand deposits.

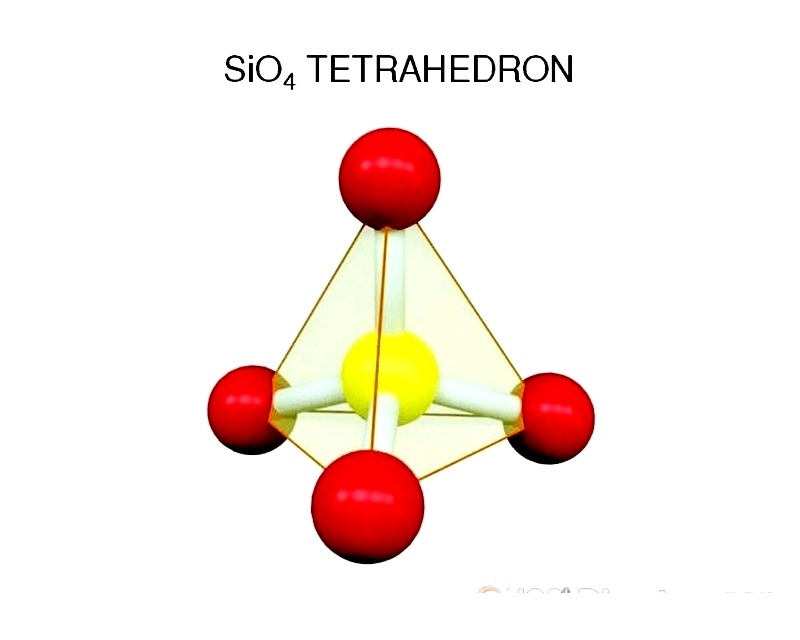

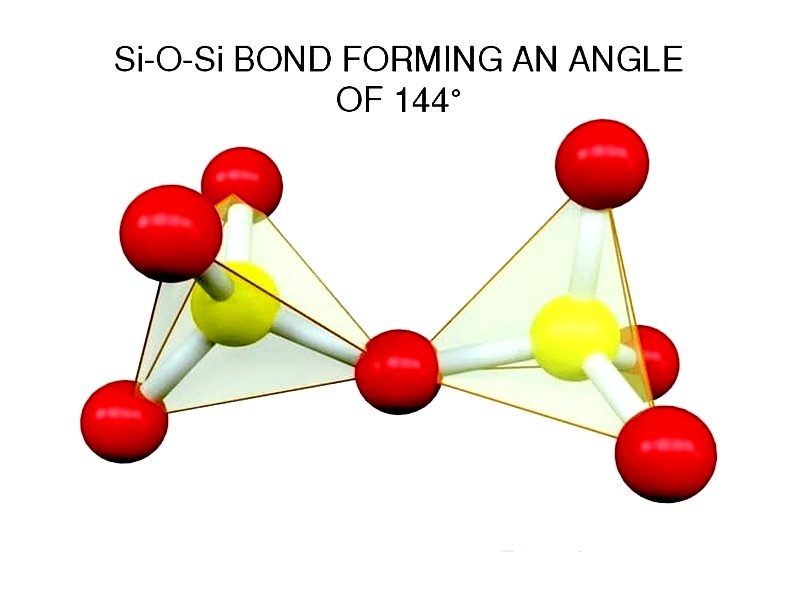

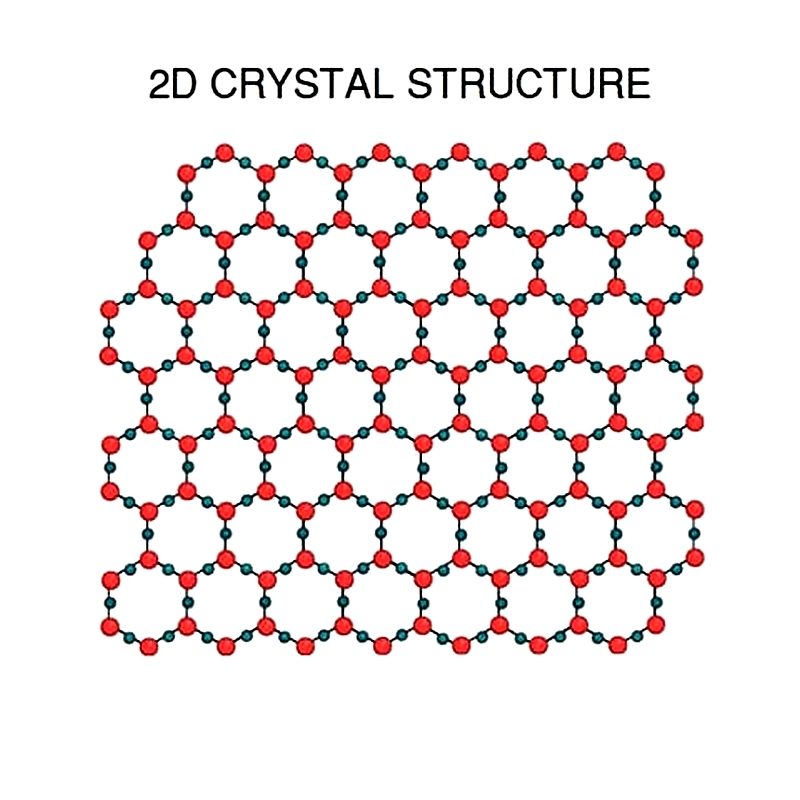

Quartz has the chemical formula SiO2, with polar covalent bonds forming between silicon and oxygen atoms. Each silicon atom, with its four valence electrons, bonds with four oxygen atoms, while each oxygen atom connects to two silicon atoms. This creates a body-centered tetrahedral structure where four oxygen atoms surround a central silicon atom, with O-Si-O bond angles of 109°. In the SiO4 network, corner oxygen atoms link central silicon atoms, forming Si-O-Si bonds at 144° angles. This open tetrahedral network results in quartz's characteristic hexagonal crystal structure.

Silica sand, essential for quartz glass production, is a durable mineral that naturally weathers into sand over time. High-quality silica sand determines the final product's strength, transparency, and color. Consistent chemical processing ensures each batch meets rigorous quality standards.

Through conversion, quartz becomes quartz glass - prized for its purity and versatility. Also known as fused quartz or fused silica, this glass contains no additives. The distinction lies in production: fused quartz uses pure silicon dioxide (SiO2), while fused silica derives from synthetic precursors.

Most quartz originates from silica sand, refined to enhance purity, strength, transparency, and color. Intensive processing removes impurities through detailed chemical treatment.

Quartz glass is highly valued for its unique properties, including low thermal expansion, excellent gas permeability, and broad optical transmission range.

Chapter Two - The Quartz Glass Production Process

This chapter details the transformation of raw quartz into high-purity fused quartz glass. Understanding each production step is crucial for industries requiring precision, durability, and superior optical performance.

Washing and Drying

The initial processing stage removes dirt, moisture, and contaminants from natural quartz crystals using industrial washing systems. This cleaning is vital for eliminating trace elements that could affect optical clarity and chemical resistance. Particularly important for naturally mined quartz, this step ensures material purity before further processing. Clean, dry quartz is essential for successful high-temperature melting into low-impurity optical glass.

Comminution

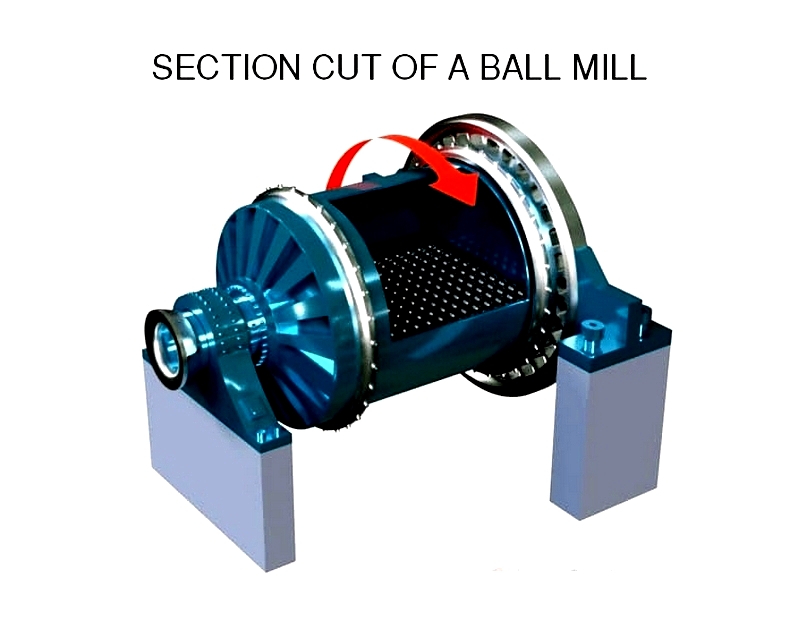

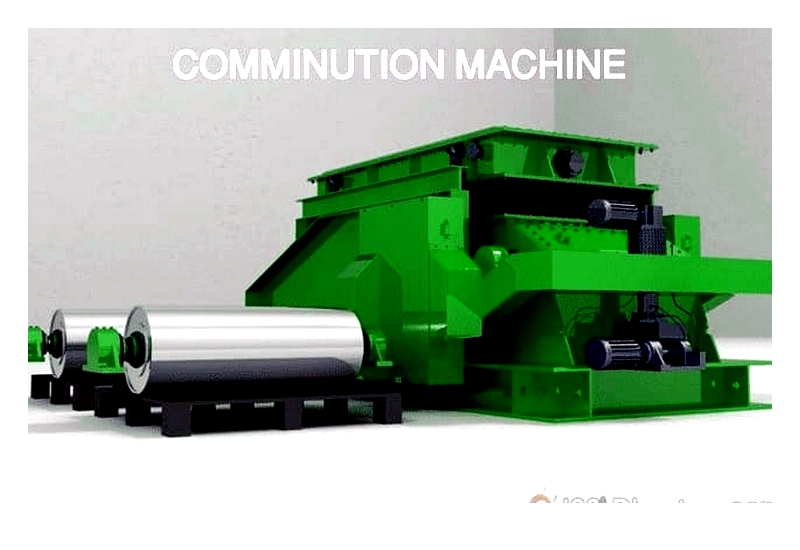

This manufacturing stage reduces raw quartz into grains or powder suitable for fusion processes. Natural quartz undergoes crushing, grinding, and milling (ball or roll milling). While quartz's brittle structure facilitates comminution, consistent particle size is crucial for uniform melting. After processing, particle size assessment ensures quality, with larger grains recycled. Uniform grain size enhances final glass transparency and structural integrity.

Fusion

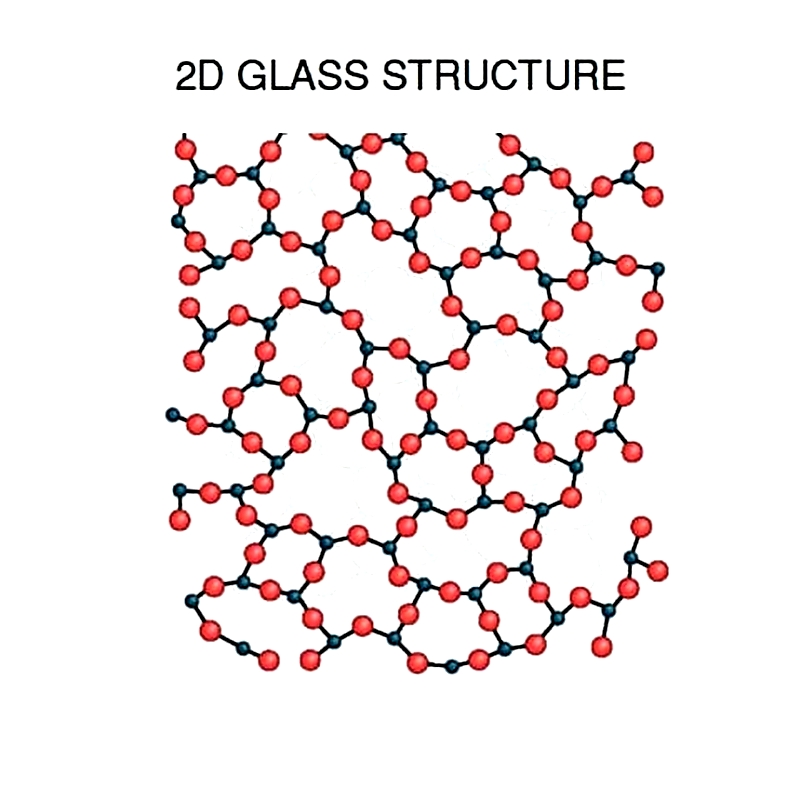

During fusion, thermal energy breaks the strong SiO2 bonds in quartz. High temperatures collapse the crystalline structure into an amorphous state - the defining step in quartz glass creation. Upon cooling, the melt solidifies into metastable glass with excellent optical properties, low thermal expansion, and high chemical purity. Fusion method control determines key properties like hydroxyl content, UV/IR transmission, and devitrification resistance - critical for semiconductor, laboratory, and photonic applications.

Depending on required purity and application, natural quartz undergoes specialized fusion methods:

Electric Fusion

This method produces Type I quartz glass with initial OH content of 100-130 ppm. For applications needing higher purity and lower OH levels (1-30 ppm), electric fusion is preferred. Vacuum annealing further reduces OH content, enhancing UV transmission and laser resistance - crucial for fiber optics and semiconductor components. Starting material is carefully screened quartz grains processed through:

- Continuous Mode: Quartz sand feeds into a refractory metal crucible with electric heating, maintained in a dry, vacuum-sealed atmosphere. Molten quartz exits through an orifice, forming plates, tubes, and rods. Ideal for high-volume industrial production.

- Batch or Boule Mode: Large quartz quantities fuse in a vacuum chamber, forming massive boules (up to 72" x 24") for machining into plates, discs, and custom components. Supports semiconductor and UV optics manufacturing.

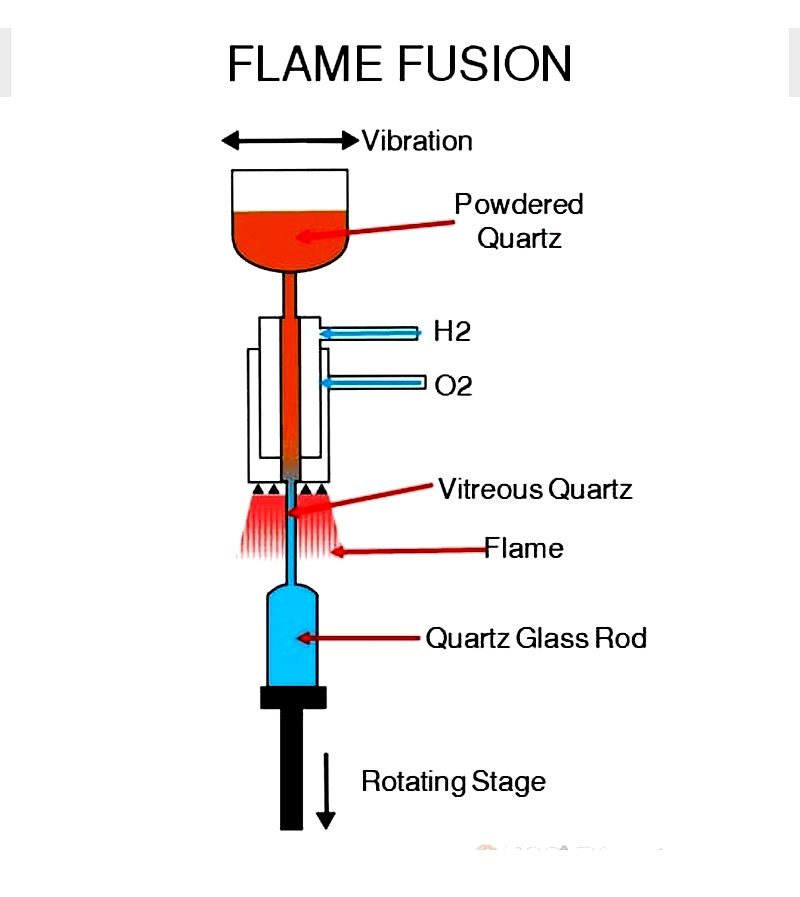

Flame Fusion

This method uses natural quartz sand or synthetic silica precursors. Natural quartz melts in a H2/O2 flame, while synthetic fusion employs silicon tetrachloride (SiCl4) vapor oxidation.

The molten quartz deposits into a vacuum chamber, forming ingots, tubes, or fibers. Resulting glass has stable OH content (150-200 ppm natural, up to 1000 ppm synthetic) unaffected by vacuum annealing. This material suits applications needing thermal shock resistance or specific transmission windows.

Flame-fused natural quartz becomes Type II glass; synthetic silica via chemical vapor deposition becomes Type III. Type III production generates hazardous byproducts requiring careful environmental management.

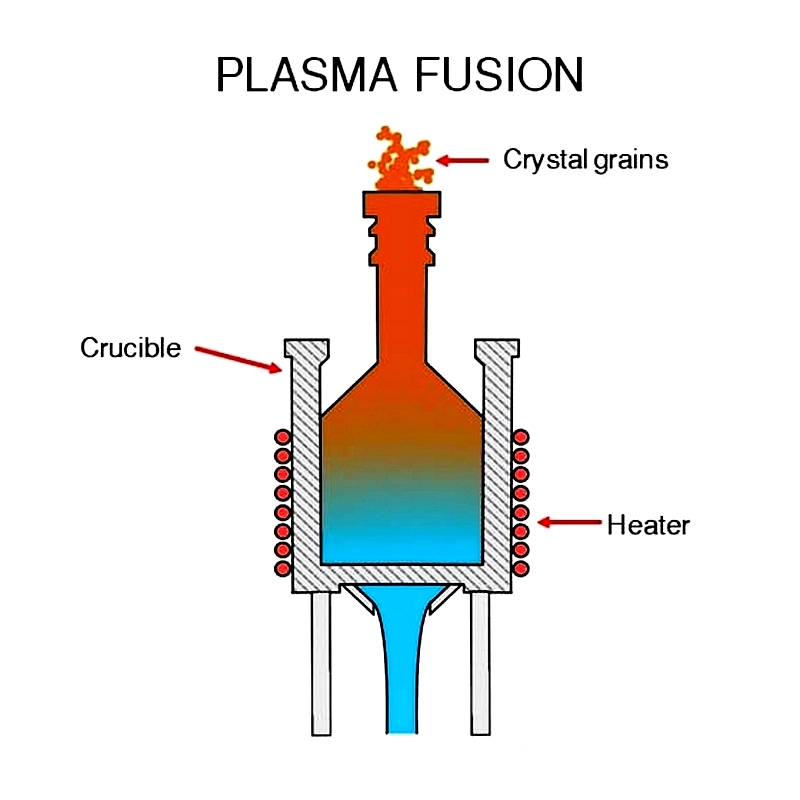

Plasma Fusion

This advanced method uses water-vapor-free plasma flames for ultra-high temperature fusion. Plasma-fused quartz offers extreme purity, minimal OH content, few bubbles, and no striations - ideal for demanding optical and semiconductor applications. Classified as Type IV when using synthetic precursors, this glass excels in homogeneity and chemical resistance.

Electric Arc Fusion

This specialized process melts quartz sand in an electric arc furnace, producing opaque, white glass with light-diffracting microbubbles. Used for thermal insulation and UV shielding rather than optics. Resulting glass has 100-130 ppm OH content and isn't classified with standard quartz glass types.

Shaping and Finishing Processes

Quartz glass forming differs significantly from conventional glass manufacturing due to its unique properties. Specialized equipment ensures purity and dimensional accuracy for microelectronics, spectroscopy, and fiber optics applications.

Mechanical Forming

Quartz glass shaping requires diamond tools, ultrasonic machining, and precision methods due to its Mohs 7 hardness. Optimized