Introduction

This guide provides a list of leading industrial air conditioner manufacturers and explains how to select the right industrial air conditioner for your needs.

You will learn about:

- What defines an Industrial Air Conditioner

- Key differences between Industrial and Residential Air Conditioners

- The manufacturing process of Industrial Air Conditioners

- Various types of Industrial Air Conditioners

- And much more...

Chapter 1: What is an Industrial Air Conditioner?

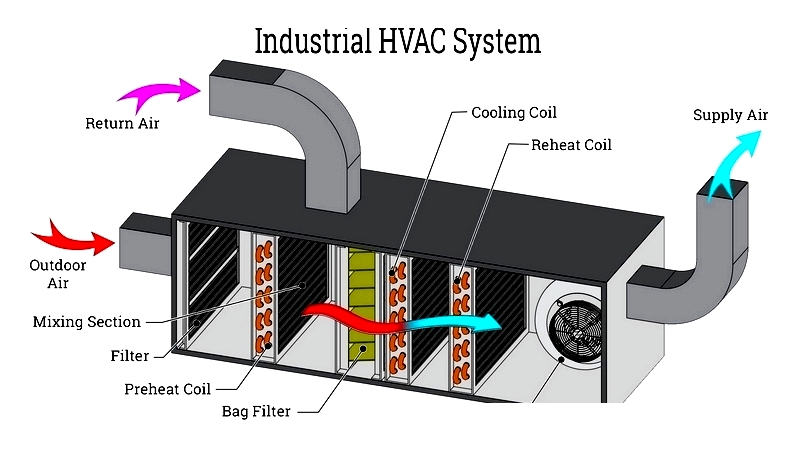

Industrial air conditioners are large-scale cooling systems specifically designed for expansive spaces like warehouses and factories. While they use similar cooling principles to residential units, industrial models feature significantly greater cooling capacity to maintain consistent temperatures across wide areas. These systems incorporate multiple compressors, numerous evaporators, extensive ductwork, powerful fans, sophisticated controllers, and advanced filtration units.

Unlike residential air conditioners focused on comfort, industrial units are essential for maintaining precise temperatures needed for handling sensitive materials, specialized processes, and equipment efficiency. They provide accurate temperature and humidity control through advanced filtration systems. Industrial air conditioners may be configured as single packaged units or distributed systems. While residential units target specific areas, industrial systems are designed to regulate temperatures across multiple zones for extended periods.

Industrial air conditioning components resemble residential versions but are distinguished by their larger size, durability, and robustness. These heavy-duty components ensure long-term reliability. The primary function of industrial air conditioning systems is to regulate temperature, humidity, and air quality across spaces often spanning thousands of square feet.

Chapter 2: Types of Industrial Air Conditioners

Industrial air conditioners are engineered to meet specific environmental conditions, process requirements, and facility sizes in commercial and manufacturing settings. Available in various sizes from compact floor models to massive rooftop units, these systems serve complex multi-story factories and warehouses. Each industrial operation requires air conditioners optimized for its particular cooling load, operating hours, and environmental challenges.

When evaluating industrial air conditioners, it's crucial to distinguish between physical size and cooling capacity, measured in British Thermal Units (BTUs). One "ton" of cooling equals 12,000 BTUs per hour. Selecting the right industrial HVAC system requires assessing the facility's cooling load, considering building volume, occupancy, equipment heat output, process heat loads, and external heat gain. Proper evaluation ensures efficient, reliable temperature control.

Correct sizing is critical for operational efficiency and energy savings. Undersized systems work harder, increasing energy costs while providing inadequate cooling. Oversized units cycle frequently, causing temperature fluctuations and unnecessary power consumption. Both scenarios affect product quality, production efficiency, and maintenance costs - key concerns for facility managers.

For optimal performance and return on investment, consult certified industrial air conditioning contractors or HVAC engineers. These professionals use proven calculation methods like Manual N and Manual J to determine proper equipment sizing and system configuration. Key factors include building insulation, ceiling height, production machinery, heat sources, airflow needs, and processed materials. Modern air conditioning solutions deliver stable temperatures while protecting personnel and products, complying with OSHA and industry standards.

Selecting industrial HVAC systems requires considering process needs, air quality requirements, energy efficiency goals, and industry-specific compliance standards. Leading manufacturers offer customized solutions with advanced controls, filtration, humidity management, and monitoring capabilities. These tailored installations help maintain product quality, protect equipment, and ensure workplace safety compliance.

In modern facilities, air conditioning is essential for worker comfort, equipment reliability, and regulatory compliance. Different environments - offices, retail spaces, distribution centers, clean rooms, and manufacturing areas - require specific types of commercial HVAC units. Common industrial cooling systems include central air conditioning, ductless splits, multi-split systems, VRF/VRV systems, and large capacity chillers. The term HVAC (Heating, Ventilation, and Air Conditioning) encompasses an even broader range of integrated environmental control systems.

Central Air Conditioning

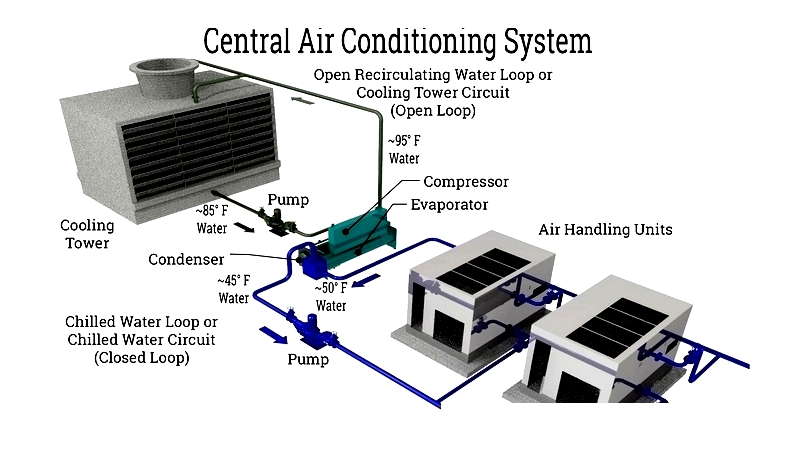

Central air conditioning systems are fundamental HVAC solutions for large facilities. Using ductwork, these systems circulate and exchange air to maintain programmed temperatures through building automation controls. By continuously replacing warm, stale air with cooled, filtered air, central AC units ensure consistent temperatures and air quality throughout large operations, supporting productivity and compliance.

Industrial central air systems differ significantly from residential models in scale and performance. While residential units typically provide 5-8 tons of cooling, industrial models often exceed 50 tons to handle the substantial thermal loads of factories, data centers, and warehouses.

Central industrial air conditioners are widely adopted for their energy efficiency, quiet operation, and seamless integration with building management systems. Available configurations include split systems, packaged rooftop units, and VRF/VRV setups, each tailored to facility layout and operational requirements. The ideal system is determined through thorough site assessment and collaboration with experienced manufacturers.

Split Central Air Conditioning System

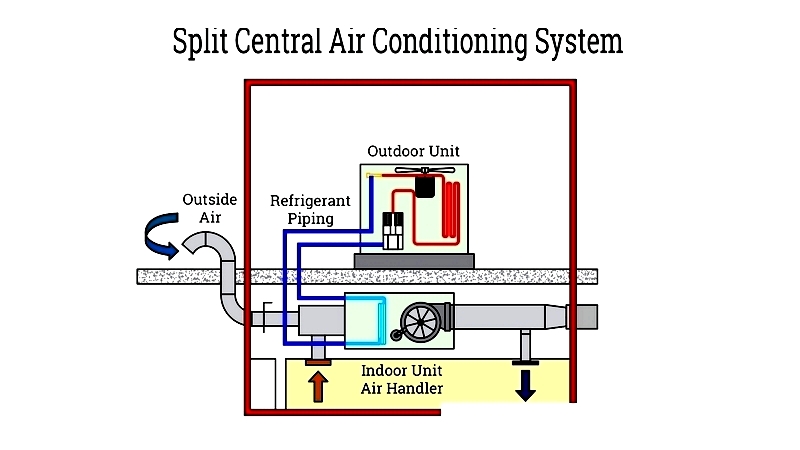

Split central air systems feature separate outdoor and indoor units, offering efficient, scalable cooling. This design improves energy efficiency and provides installation flexibility while reducing noise in industrial environments. Split systems are ideal for spaces requiring zoned temperature control, such as server rooms and laboratories.

Ducted split systems connect outdoor units to indoor blowers via ductwork, while ductless variants (mini-splits) install air handlers directly in conditioned zones. Ductless systems reduce maintenance needs by minimizing dust accumulation, making them suitable for modular offices and retrofit applications.

Split systems offer greater flexibility in installation, energy management, and zoning compared to packaged rooftop units. Their modular design supports cost-effective upgrades and repairs. System components are connected via refrigeration piping and low-voltage wiring.

Packaged Central Air Conditioning System

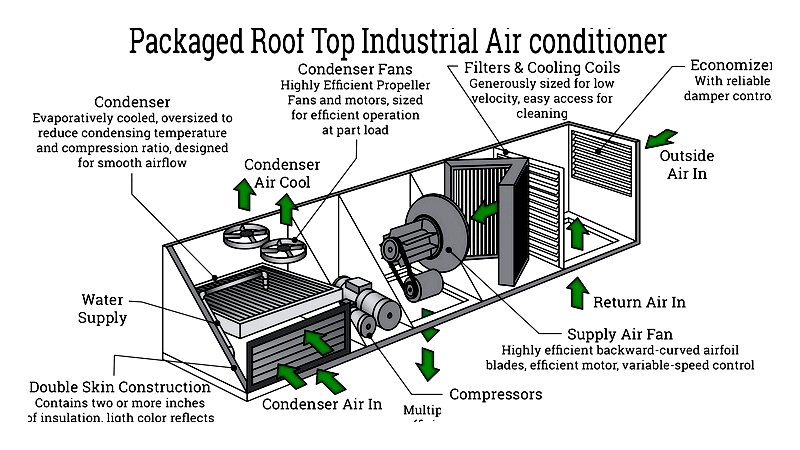

Packaged rooftop units (RTUs) are all-in-one systems commonly used in industrial and large commercial applications. These weatherproof units combine all components in a single housing, typically installed on roofs or service pads. RTUs simplify installation and maintenance while freeing up valuable indoor space.

Packaged systems feature reinforced construction, heavy-duty components, and advanced filtration. Configurations may include air-cooled or water-cooled condensers to suit different energy infrastructures. These solutions are ideal for industrial plants, logistics centers, and office buildings requiring centralized cooling for multiple zones.

Industrial packaged units exceed residential equivalents in durability and performance. Advanced features like variable speed drives and remote monitoring optimize system performance for lower lifecycle costs.

Variable Refrigerant Flow (VRF) and Variable Refrigerant Volume (VRV) Industrial Air Conditioners

VRF/VRV systems represent advanced HVAC technology for precise, efficient climate control in multi-zone environments. These systems connect multiple indoor units to inverter-driven outdoor compressors, using smart refrigerant management to match real-time cooling and heating demands.

VRF systems differ from traditional central air by using refrigerant as the sole heat transfer medium. Their inverter compressor technology adjusts output to meet fluctuating demand, reducing wear and improving efficiency. This variable control maintains stable temperatures while saving energy.

The modular design allows custom configurations with individual zone controls and occupancy sensors. Networked controls integrate with building automation systems. This precise control prevents temperature fluctuations while optimizing energy use.

Available in cooling-only, heat pump, and heat recovery versions, these ductless systems are ideal for buildings with architectural constraints. Their environmentally friendly refrigerants support sustainability goals and regulatory compliance.

VRF/VRV technology suits modern construction and retrofit projects focused on energy efficiency. While initial costs are higher, long-term energy savings and improved comfort offset this investment. These systems offer smart controls and predictive diagnostics,