Introduction

This article provides an in-depth exploration of linear actuators.

You will learn about various topics including:

- What is a linear actuator?

- Different types of linear actuators

- Key considerations

Understanding Linear Actuators

A linear actuator, also known as a ram, piston, or activator, creates straight-line movement to perform specific tasks. These devices are common in both household appliances and industrial settings, serving important functions in equipment like computer disk drives and printers. Fundamentally, a linear actuator generates linear force. Historically, the concept of linear motion was demonstrated through simple applications like using a heavy tree trunk as a battering ram.

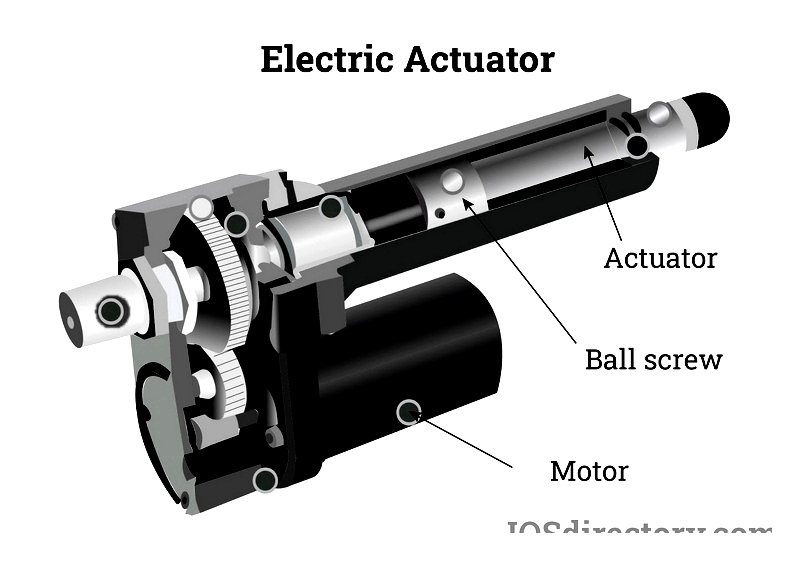

The main types of linear actuators include screw-driven, wheel and handle, and cam-based models. Screw-driven actuators operate through the rotation of a screw mechanism. Wheel and handle actuators use belts or chains connected to a shaft to produce movement. Cam actuators employ an eccentric circle to drive shaft motion.

While definitions may vary by industry, linear actuators are generally understood as devices that transform rotational force into linear motion. This initial force can come from manual cranking or electric motors, which is then transferred to a linear mechanism.

Linear actuators provide smooth, precise, and quiet operation with minimal maintenance requirements. Their robust construction, energy efficiency, and customizable designs make them essential components in manufacturing and various other applications.

Linear actuators originated during the Industrial Revolution to handle increasingly sophisticated machinery. They became crucial elements in hydraulic and pneumatic systems within steam engines, where pistons converted steam power into mechanical energy.

The modern electric actuator was invented in 1979 by Danish entrepreneur Brent Jensen to improve wheelchair functionality. His design allowed for height adjustment, significantly enhancing user comfort. Jensen later expanded this concept beyond its original purpose, leading to the development of the first electric actuator.

Before Jensen's innovation, electric motors were limited to rotational movement. His breakthrough revealed new potential applications for electric motors, dramatically increasing their utility. The wheelchair mechanism demonstrated numerous practical uses for this technology.

Jensen's company further developed these systems for agricultural equipment, particularly improving forage harvesters with linear actuators that efficiently loaded silage into storage. After proving successful in agriculture, linear actuators became widely adopted across multiple industries as reliable and efficient solutions.