Introduction

Explore everything you need to know about wastewater evaporators in this comprehensive online guide, which covers:

- Definition and Function: What wastewater evaporators are and how they work

- Industrial Applications: The various industries that use wastewater evaporators

- Varieties: Different types of wastewater evaporators and their specific applications

- Other essential information to enhance your understanding

Chapter One – Understanding Wastewater Evaporators

A wastewater evaporator works by converting water-based waste into vapor, separating impurities and reducing waste volume. This process is vital for efficient waste management.

Wastewater treatment is strictly regulated to ensure proper management. Manufacturers of wastewater evaporators collaborate with regulatory agencies to guarantee environmentally safe disposal of industrial waste.

Chapter Two - How Does a Wastewater Evaporator Work?

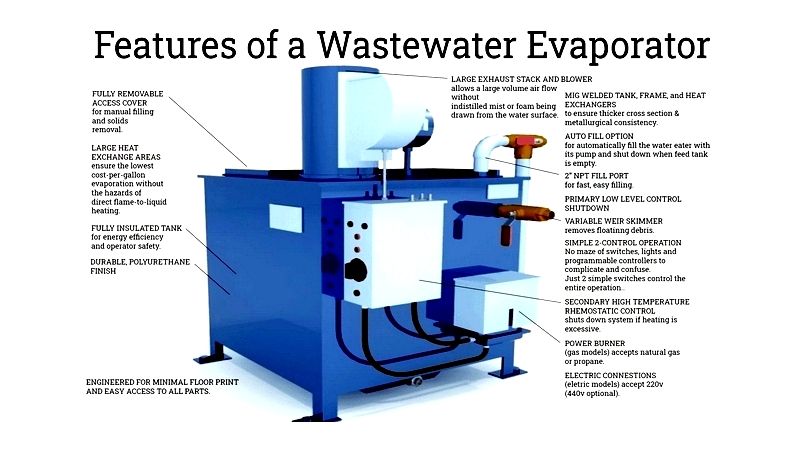

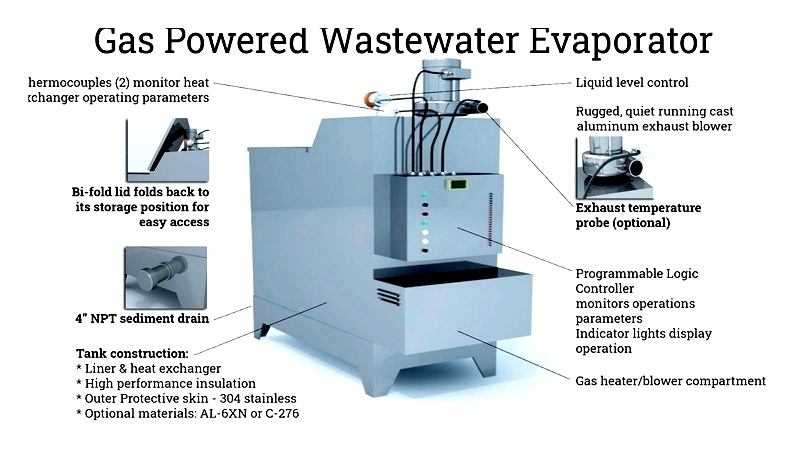

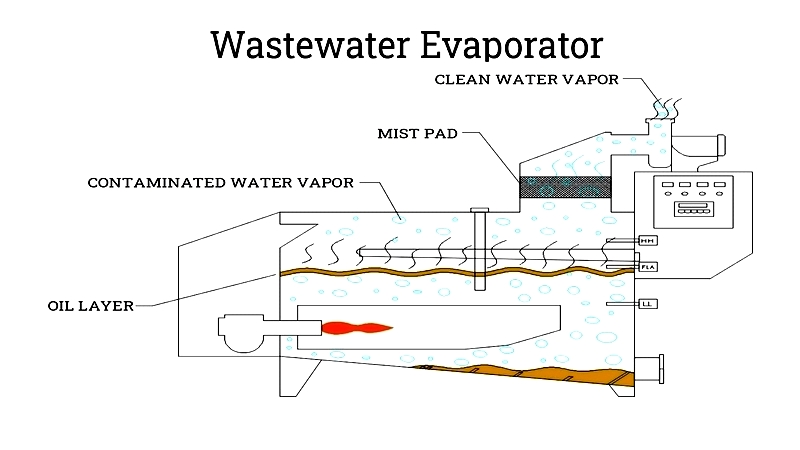

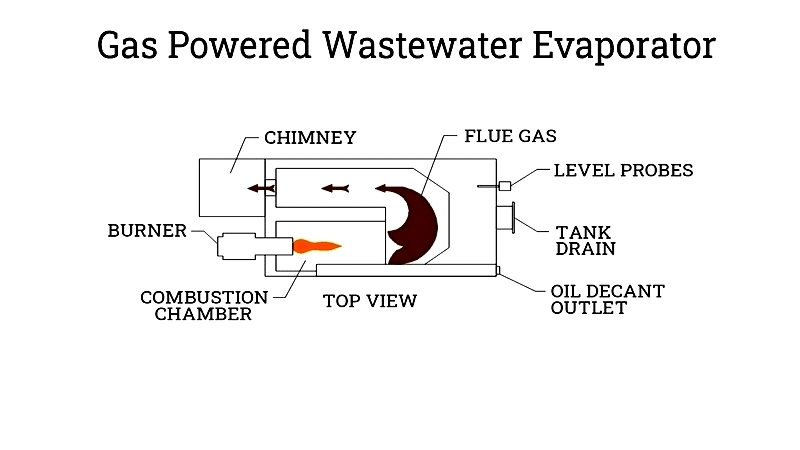

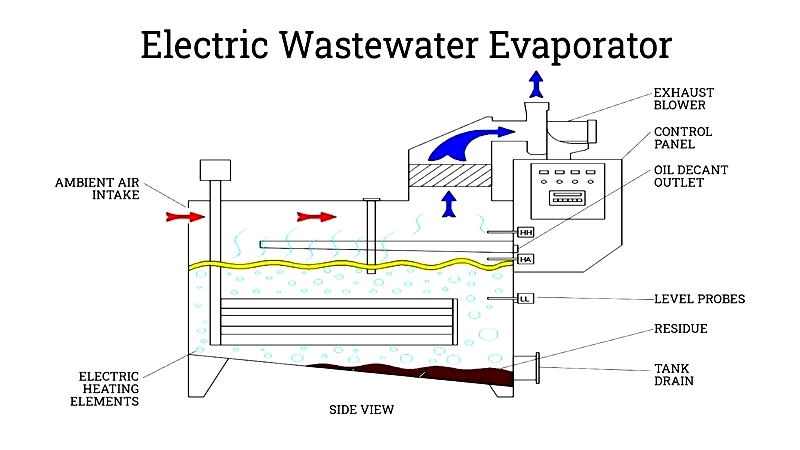

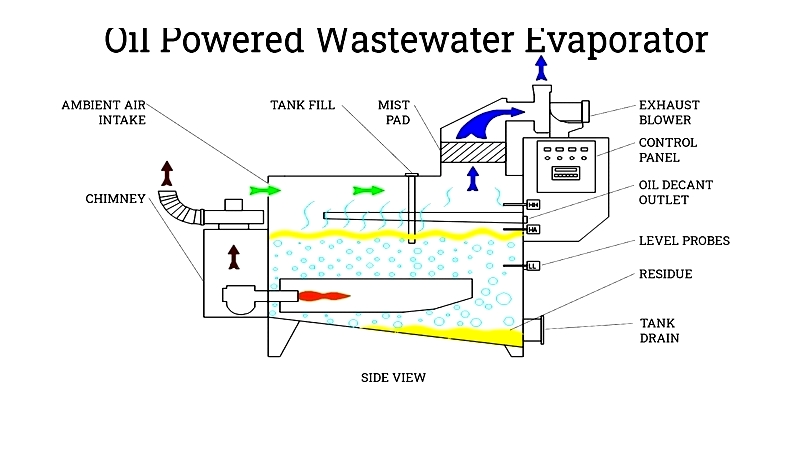

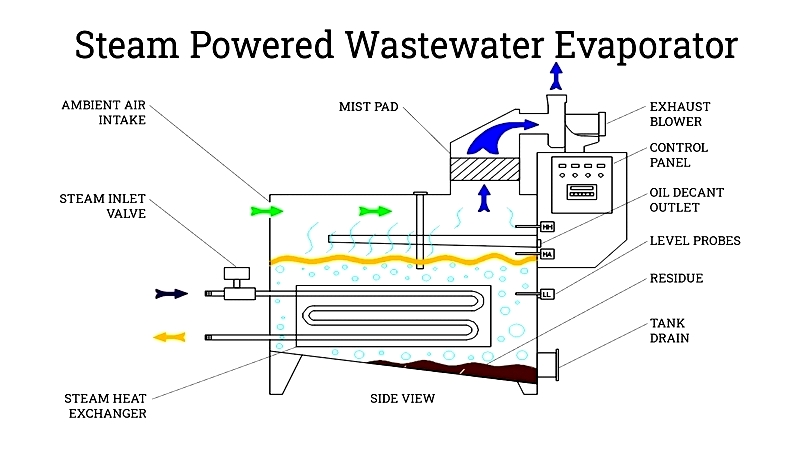

A wastewater evaporator is an advanced industrial treatment system that uses thermodynamics and mass transfer to separate water from waste materials. Thermal energy heats the liquid waste until the water vaporizes, significantly reducing waste volume. Common energy sources include natural gas, electricity, oil, or steam, making these systems adaptable for various industrial applications.

After vaporization, a blower moves the water vapor without additional filtration. This method effectively treats challenging substances like organic compounds, heavy metals, oils, salts, and hazardous chemicals.

Modern evaporators provide a more efficient alternative to traditional solar evaporation ponds, which require large land areas and have slower operation speeds. Mechanical and thermal systems improve evaporation rates, reduce land use, and ensure faster, more reliable wastewater reduction. These systems are increasingly used for liquid waste concentration, pollutant removal, and compliance with environmental regulations.

Operation of a Wastewater Evaporator

Feed

Raw wastewater from industrial processes, rinse water, or contaminated liquids is collected in a holding tank. This pre-treatment stage ensures consistent metering into the evaporator, improving efficiency in batch or continuous operations.

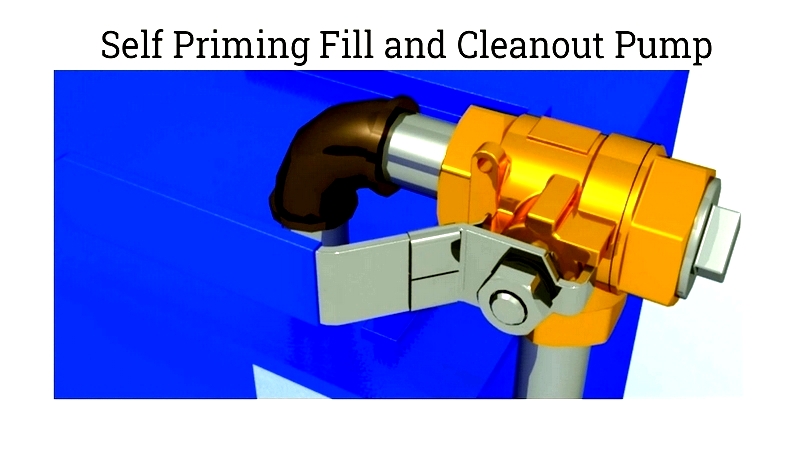

Feed Pump

A feed pump transfers wastewater into the evaporator chamber. The pump can be manual or automated, adjusting to the wastewater's viscosity and composition, from high-solid slurries to clear effluents.

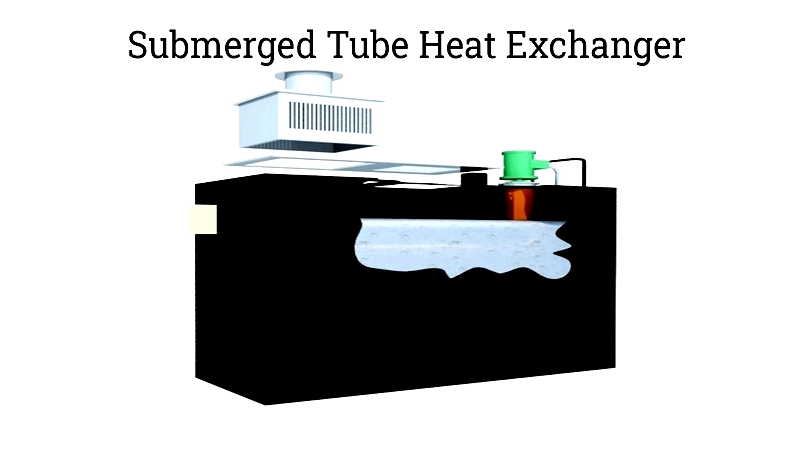

Heat

A heat exchanger applies thermal energy to the wastewater, raising its temperature to near boiling. This process vaporizes the water, concentrating solids into a smaller volume. Efficient heat management is crucial for speed and energy consumption.

once the desired concentration is reached, the system signals for sludge removal, ensuring long-term reliability.

Blower

A blower moves air through the evaporator, removing water vapor and maintaining optimal temperatures. Forced or induced draft blowers enhance evaporation rates and control odors, ensuring safe operation in industrial settings.

Compressor

Compressors in mechanical vapor recompression (MVR) systems boost efficiency by recycling latent heat. These systems reduce energy consumption and operational costs, making them ideal for high-volume industrial effluent treatment.

Mist Eliminator

A mist eliminator removes droplets and contaminants from the vapor stream before discharge. Made from corrosion-resistant materials, it ensures compliance with environmental regulations and reduces maintenance needs.

Heat Production in a Wastewater Evaporator

Gas

Gas-fired evaporators use burners to heat wastewater quickly, making them suitable for oily or high-contaminant wastewater in industries like manufacturing and metal finishing.

Electric

Electric models use heating elements for precise temperature control, requiring less maintenance. They are ideal for small-scale operations or facilities without gas access, such as laboratories.

Oil

Oil-fired systems operate similarly to gas units, using fuel oil for heavy-duty applications with corrosive or high-solids wastewater.

Steam

Steam-powered systems heat wastewater efficiently using direct or indirect steam, making them popular in chemical and food processing industries.

Additional Considerations for Wastewater Evaporator Selection

Key factors include wastewater composition, evaporation rates, energy use, discharge standards, and total ownership cost. Zero liquid discharge (ZLD) systems ensure regulatory compliance, while automation and remote monitoring enhance efficiency.

Investing in the right wastewater evaporator can optimize operations, improve sustainability, and protect your facility from environmental risks.