Introduction

This article provides an in-depth examination of ceramic heaters.

Continue reading to explore topics including:

- What ceramic heaters are

- The scientific principles behind ceramic heaters

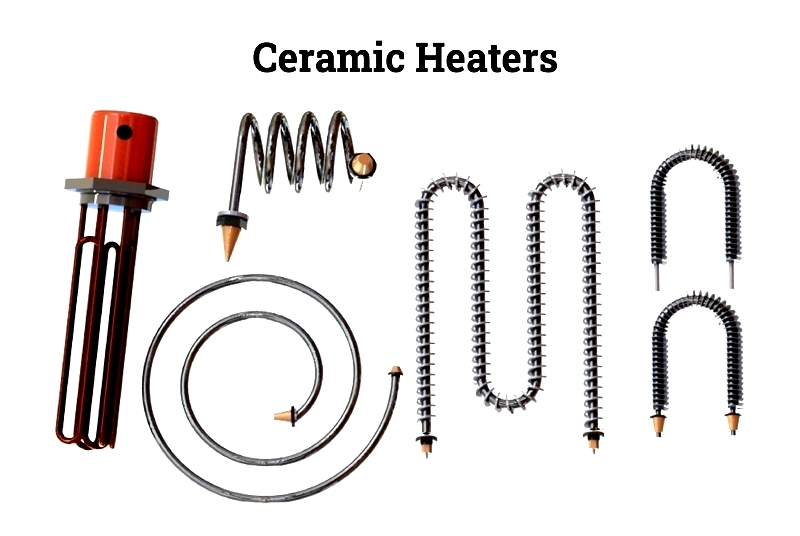

- Different types of ceramic heaters

- Benefits of using ceramic heaters

- And more...

Chapter 1: What is a Ceramic Heater?

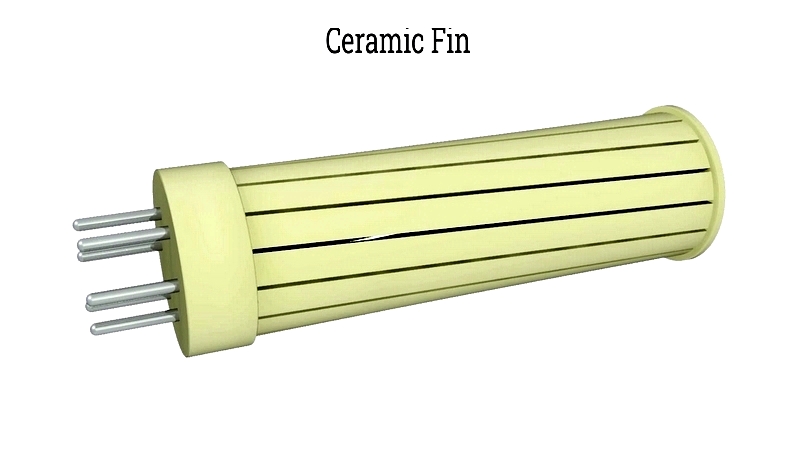

Ceramic heaters are a type of electric heater that incorporate positive temperature coefficient (PTC) ceramic elements. They operate on the principle of resistive heating. Ceramic materials possess significant electrical resistance and excellent thermal conductivity, enabling efficient heat generation and transfer when electricity flows through them. Their durability and strength make them ideal heating elements. While some ceramic heaters use pure ceramic cores, many combine ceramic and metal components. In these composite designs, the ceramic acts as both an effective insulator and heat conductor, minimizing energy and heat loss that typically occurs with exposed resistance wires.

Widely used in industrial applications like drying, boiling, molding, and melting, ceramic heaters are also common for space heating. Their ability to provide quick, safe, and clean heating makes them versatile for various uses.

Chapter 2: The Science Behind Ceramic Heaters

This chapter examines the scientific principles underlying ceramic heater design and operation, focusing on how these efficient devices use resistive heating, advanced ceramics, and safety features to deliver reliable warmth. Their superior performance, durability, and precise temperature control make ceramic heaters popular for residential, commercial, and industrial applications. Understanding their science helps users make informed choices when comparing models.

Ceramic heaters function through resistive heating, also called Joule heating or Ohmic heating. This occurs when electric current passes through resistive elements like PTC ceramics or ceramic plates, generating heat as a byproduct of resistance. This conversion of electrical to thermal energy makes ceramic heaters both safe and energy-efficient. While resistive losses are undesirable in power transmission, they're harnessed in ceramic space heaters to maximize heat output.

Joule's first law (P = I²R) quantitatively describes this heat generation, guiding the design of ceramic heating elements for compact, fast-warming devices.

Molecular Basis of Resistive Heating

At the molecular level, current flow through ceramic materials causes electron collisions that generate vibrations and heat. This fundamental process powers all electric space heaters. Premium ceramic heaters optimize this mechanism while minimizing energy waste, offering quick heating and safe surface temperatures.

Material Resistance Properties

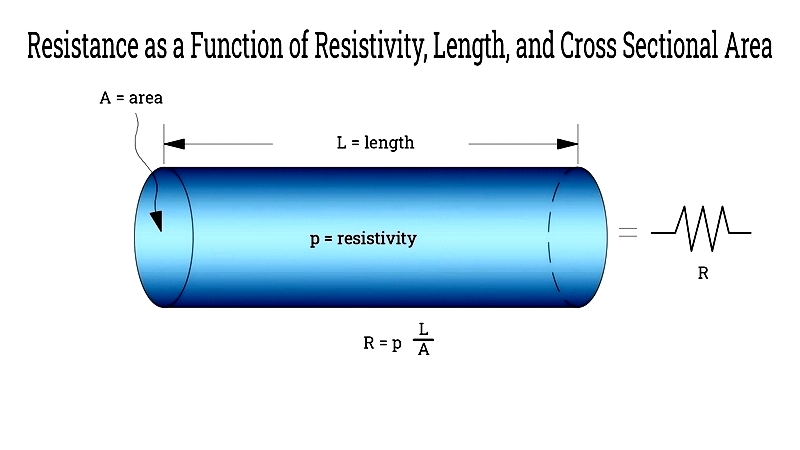

Resistance (R = ρL/A) depends on material dimensions and resistivity (ρ). Ceramic heaters use materials with carefully balanced resistance to ensure optimal heat generation and longevity across applications from infrared heaters to ceramic fan heaters.

Heat Transfer Methods

Ceramic heaters distribute heat through three mechanisms:

- Conduction: Direct heat transfer to contacting materials

- Convection: Air circulation via fans or natural flow

- Radiation: Infrared emission for targeted warmth

These methods, combined with safety features like cool surfaces and overheat protection, make ceramic heaters ideal for home and office use.

PTC Self-Regulation

PTC ceramics automatically reduce current flow when reaching setpoint temperatures, providing inherent safety and energy efficiency. This self-regulating property distinguishes ceramic heaters from traditional metal coil heaters, eliminating overheating risks while maintaining precise temperature control.

Understanding these scientific principles helps consumers evaluate ceramic heaters based on heating speed, uniformity, safety, and energy efficiency when selecting models for personal or commercial use.