Introduction

This comprehensive guide covers all essential information about modular clean rooms and their applications.

You will discover:

- The definition of Modular Clean Rooms

- Applications of Modular Clean Rooms

- Industries utilizing Modular Clean Rooms

- Standards governing Modular Clean Rooms

- Additional valuable insights

Chapter One – Understanding Modular Clean Rooms

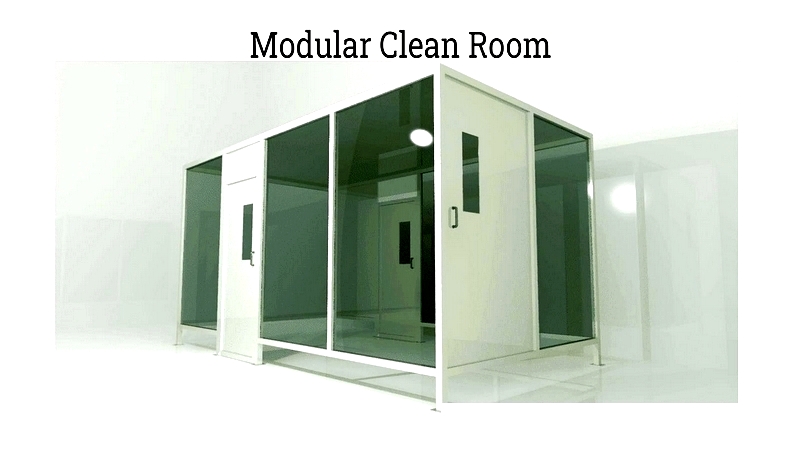

A modular clean room is a pre-engineered controlled environment designed to minimize and regulate sub-micron particles. These spaces are built using prefabricated panels that integrate seamlessly into a structural framework. Available as self-assembly kits or professionally installed solutions, modular clean rooms offer cost-effective alternatives to traditional constructions due to their simplified design and economical components.

The adaptable nature and quick installation of modular clean rooms make them ideal for urgent project requirements, enabling rapid deployment and operational readiness.

Modular clean rooms primarily fall into two categories based on wall construction: hard wall and soft wall. Hard wall variants feature durable panels made from materials like plastic, aluminum, gypsum, or wood, while soft wall clean rooms utilize curtain-based systems typically constructed from plastic or vinyl materials.

Chapter Two – Applications of Modular Clean Rooms

Modular clean rooms serve as versatile, customizable enclosures that create controlled environments for manufacturing and laboratory settings. Their modular design allows for quick assembly and adaptation to existing spaces, maintaining precise control over air quality, humidity, pressure, temperature, and particulate levels. These flexible systems are crucial for industries requiring strict contamination control, meeting ISO classifications and GMP guidelines. As standalone units, they provide pristine conditions for product testing, quality control, assembly, packaging, and research applications.

The precision engineering of modular clean rooms creates isolated environments that protect sensitive processes from contaminants like dust, bacteria, microorganisms, airborne particles, and temperature variations. Industries including pharmaceuticals, biotechnology, medical devices, microelectronics, aerospace, automotive, food processing, and research laboratories extensively utilize these solutions. Their scalable, prefabricated design supports temporary, mobile, or permanent installations tailored to evolving production needs.

Key Applications of Modular Clean Rooms

Epidemic Testing

The mobility and rapid deployment capability of modular clean rooms make them invaluable for emergency response situations, particularly epidemic and pandemic testing. Portable modules facilitate on-site medical diagnostics, sample processing, and biosafety operations in areas lacking permanent laboratory infrastructure. This capability proves especially beneficial in remote or resource-limited regions during public health emergencies.

Facility Expansion

For growing companies needing increased production capacity, modular clean rooms offer efficient expansion solutions for laboratories and manufacturing areas. Their pre-engineered panels enable operational readiness within a day, minimizing downtime and construction costs. This rapid deployment makes them ideal for adapting to changing workflow requirements or meeting new regulatory standards without lengthy construction periods.

Hazardous Waste Management

Modular clean rooms serve as effective containment solutions for hazardous waste handling, storage, and disposal. Designed to capture chemical fumes, particulates, and biological agents, they mitigate risks associated with spills and cross-contamination. These systems provide essential protection for industries requiring emergency decontamination or temporary quarantine spaces.

Educational Research

Academic institutions utilize modular clean rooms as cost-effective solutions for research and laboratory training. These controlled environments provide safe spaces for students to learn contamination control and sterile techniques. For budget-conscious schools, they offer economical alternatives to conventional construction while allowing future reconfiguration as program needs evolve.

Advanced Cleaning

Modular clean rooms provide isolated spaces for thorough decontamination and precision cleaning beyond standard protocols. Equipped with HEPA filtration and customizable layouts, they support manufacturers facing short-term projects or unexpected contamination events. Even companies without permanent cleanroom needs benefit from temporary installations for compliance with regulatory standards.

Pollutant-Free Environments

Engineered to maintain ultra-clean conditions, modular clean rooms eliminate airborne contaminants critical for sensitive processes. Their high-efficiency filtration systems meet ISO classifications from 5 to 8, ensuring compliance with clean manufacturing requirements. Quick installation minimizes downtime in critical applications like semiconductor production and pharmaceutical preparation.

Chemical Handling

Modular solutions provide controlled environments for hazardous chemical processing and analysis. Their customizable airflow management and integration with safety systems create reliable workspaces while reducing operational expenses compared to permanent structures.

Precision Assembly

Industries requiring contamination-free assembly environments benefit from modular clean rooms' configurable controls and flexible layouts. These systems support electronics, optics, aerospace, and food packaging operations, enabling just-in-time production and easy process adaptation.

CNC Operations

Modular enclosures protect CNC equipment from environmental factors affecting precision machining. These solutions extend machine life, improve product yields, and can incorporate temperature control and automation features. Available in various ISO classes, they offer cost-effective compliance solutions for high-tolerance manufacturing.

Emerging Applications

Modular clean rooms are expanding into nanotechnology, regenerative medicine, and advanced manufacturing fields. Their compliance with international standards and flexible acquisition options make them attractive for R&D and product development. When selecting providers, consider certification, system specifications, integration capabilities, and support services to ensure optimal performance and compliance.