Introduction

This section provides information about security booths and shelters, including their applications along with a list of manufacturers and their products.

You will learn about:

- The definition of Security Booths and Shelters

- Manufacturing processes for Security Booths and Shelters

- Practical applications of Security Booths and Shelters

- Different varieties of Security Booths and Shelters

- And additional relevant information...

Chapter 1: Understanding Security Booths and Shelters

Security booths and shelters are modular structures manufactured off-site under controlled conditions before being transported to their final locations as complete units. These structures provide an efficient solution for creating temporary or permanent shelter and protection for personnel across various sites. Their use offers a cost-effective approach to quickly organize spaces or enhance security measures. Due to their affordability, simple installation, and durability, they are among the most commonly used temporary structures.

Despite their modular nature, security booths and shelters incorporate the same high-quality materials found in permanent buildings. Their assembly must comply with building codes, construction standards, and local regulations. These prefabricated structures arrive fully assembled, wired, painted, and ready for immediate use. Many are customized to meet specific environmental conditions and unique operational requirements.

Chapter 2: Security Booth and Shelter Construction

The design and construction of security booths and modular guard shelters incorporate comprehensive comfort, safety, and security features essential for on-site personnel. Guard shacks and access control booths typically feature ergonomic workstations for paperwork, digital record-keeping, and surveillance monitoring. This setup enables security staff to efficiently document vehicle and personnel movements, monitor access points, log incidents, and store relevant data. Integrated power, data connections, and lighting solutions are crucial for supporting 24/7 operations and real-time communication with command centers.

Commercial, industrial, educational, and government facilities utilize various types of security booths and shelters, including vehicle inspection points, elevated observation towers, event ticket booths, and perimeter guard houses. Determining the optimal number and placement of prefabricated security shelters requires thorough site risk assessments and consideration of each facility's unique security needs. Organizations in sensitive sectors like defense or critical infrastructure may require advanced ballistic-rated booths with blast-resistant construction per government or DoD MilCon specifications.

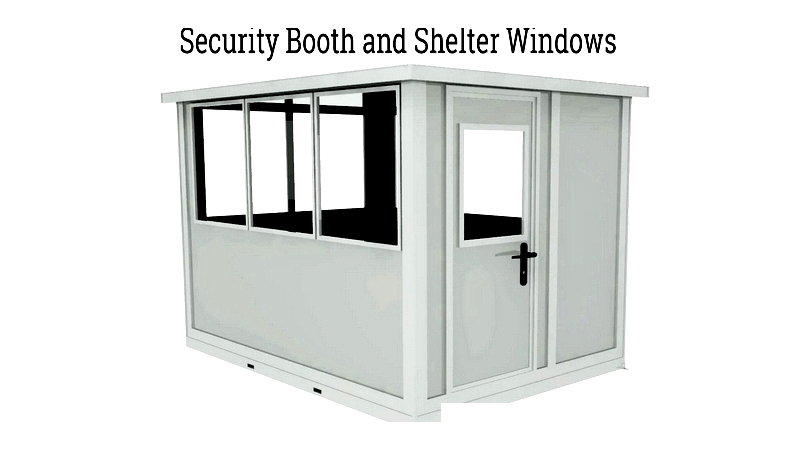

Unlike standard modular buildings, security booths require high-visibility windows on all sides. Panoramic windows maximize visibility, allowing security personnel to detect potential threats from any direction. Security glass is often specified for enhanced protection against breakage, forced entry, and harsh weather conditions, supporting both safety and vigilance.

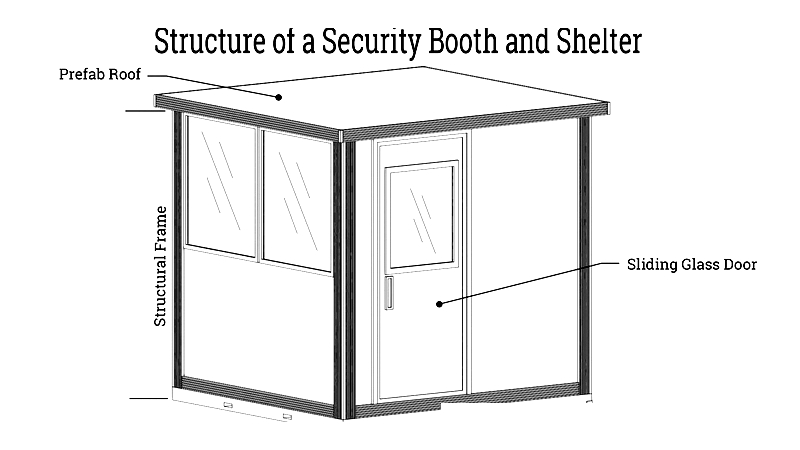

Key components include heavy-duty wall panels, reinforced roofs, insulated floors, secure doors, tamper-proof windows, advanced insulation, and integrated HVAC systems. These elements are engineered using high-performance materials like galvanized steel, anodized aluminum, stainless steel, and composite panels to meet industry standards for strength, security, and durability. This construction ensures long service life, low maintenance, and protection against vandalism, forced entry, and severe weather.

Walls

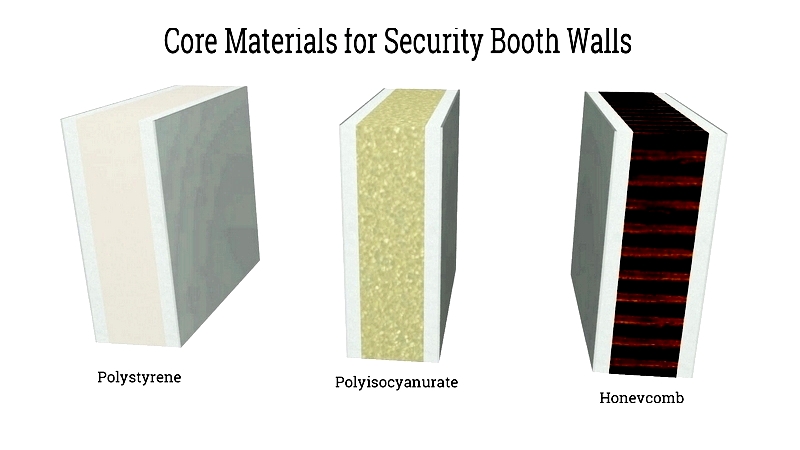

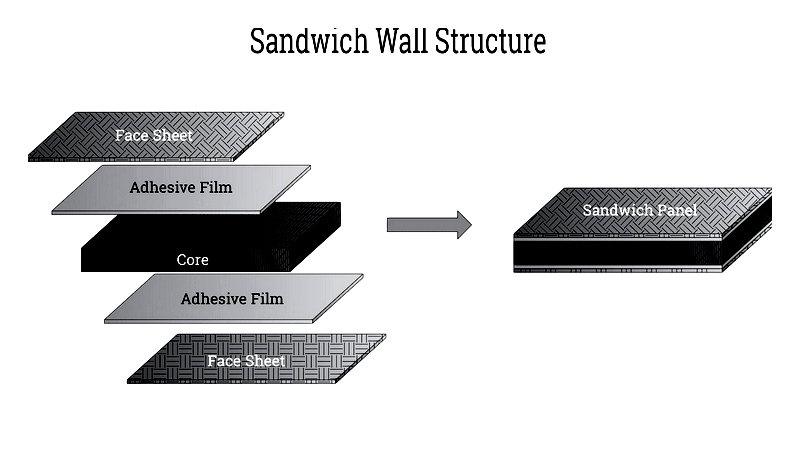

The protective capability of a security booth largely depends on its wall system. Modern guard booths typically feature steel or aluminum frames with solid-core infill materials providing both insulation and ballistic protection. Wall panels often use layered sandwich construction, combining exterior and interior sheets with structural and thermal cores. High-strength cores may include steel, high-density polyurethane foam, mineral fiber, or ballistic materials, selected based on required threat resistance levels.

Various wall systems like insulated metal panels or reinforced fiberglass composites are engineered to provide specific security levels. Sandwich panel construction offers durability, thermal efficiency (with R-values from R-13 to R-21+), and quick installation. Walls must resist physical attacks while providing soundproofing and climate control. Exterior finishes like fiberglass reinforced plastic, painted galvanized steel, or anodized aluminum offer weatherproofing and professional appearance, while inner cores maintain strength and insulation.

For high-risk environments, walls can be upgraded with bullet-resistant or forced-entry rated materials meeting UL 752 or NIJ standards. These customizable options allow facility managers to select security solutions tailored to their specific risks and requirements.

All wall system layers are bonded with industrial-grade adhesives to create a robust, unified structure resistant to delamination. The adhesive selection depends on panel composition, ensuring long-term performance and safety.

Windows

Window design significantly impacts surveillance effectiveness and personnel safety. Security booths feature various window configurations—panoramic, three-sided, dual-sided, or single—depending on placement and visibility needs. Options include sliding, fixed, or vision-blocking panels, all designed for heavy-duty use and environmental resistance. Standard features include weather stripping and locking hardware. Tinted, mirrored, or reflective glass options provide privacy while reducing glare and heat.

Window glass typically uses clear, tempered safety glass, with upgrades available for laminated, impact-resistant, or bulletproof glazing in high-risk locations. Tint options (gray, bronze, green, blue) help control solar gain while maintaining visibility. High-security applications may use one-way observer or anti-bandit glass. Standard window placement is typically 43 inches (109.22 cm) above floor level, with custom designs available.

Roof

The roof structure provides environmental protection, temperature regulation, and overall durability. Roofing systems typically combine corrugated or flat steel panels with structural grids and weather barriers. Roof section dimensions are scaled to booth size and performance requirements. Standard 24-inch (60.96 cm) overhangs help manage precipitation and solar exposure, with options for reinforcement in larger structures.

Ceiling grid options include gasket-sealed aluminum, corrugated steel, or structural steel/aluminum for supporting equipment like cameras, lighting, or HVAC components. Roof insulation and radiant barriers help maintain interior comfort in various climates. Exterior finishes typically use powder-coating or anodizing for corrosion resistance in exposed locations.

frame

The internal frame provides structural support and withstands daily operational stresses. Security booth frames use heavy-gauge steel or aluminum tubing, with extensive welding or bolting for enhanced rigidity and tamper resistance. Reinforced corners and additional welds protect against mechanical damage.

frame assemblies range from standard-duty to military-grade ballistic designs. Flexible framing allows integration of electrical, communication, and security systems, and supports permanent, semi-permanent, or relocatable deployment. Modern modular framing techniques streamline installation and relocation using quick-connect systems and prefabricated modules.

All components securely connect to the frame, creating a stable enclosure. While differing from conventional building frames, these designs maintain equivalent strength, longevity, and code compliance.

base

The base supports all structural and mechanical elements. Options include static (permanently anchored), palletized (forklift-movable), or trailer-mounted configurations. bases must support total weight while allowing relocation when needed. Specialized designs accommodate unique requirements, such as shock-absorbing mounts for mobile units or anchor points for permanent installations.

Flooring typically features slip-resistant coatings and integrated cable management. Collaboration between manufacturers and clients enables fully customized solutions for challenging environments, specialized scenarios, and advanced threat levels. Options