Introduction

This article provides comprehensive information about hose reels, covering their various types and applications.

You will learn about:

- The definition of a Hose Reel

- Different Types of Hose Reels

- Practical Applications of Hose Reels

- Key Features and Characteristics of Hose Reels

- And much more...

Chapter One – Understanding Hose Reels

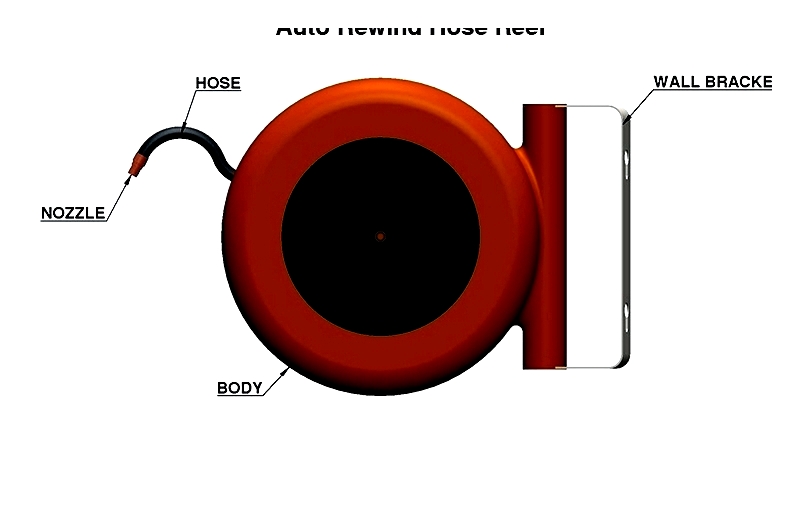

A hose reel is a specialized device designed for storing and managing hoses, typically mounted on a drum or barrel for convenient access. This organizational solution efficiently stores hoses, cords, flexible tubes, and wires, ensuring they remain readily available when needed.

Different hose reel types serve specific purposes, with some models expertly handling various cord-like materials.

Hose reel cylinders are constructed from durable materials like metal, fiberglass, or plastic. The most common spring-driven models automatically retract the hose, while other options include hand-cranked and motor-driven versions. A reel's capacity depends on its cylinder diameter and the length of hose it can accommodate.

Hose Reel Operation

Hose reels efficiently store and dispense hoses, offering practical solutions for gardening, firefighting, and industrial applications. They prevent kinks and tangles while ensuring convenient access and storage.

The basic design features a cylindrical drum made from sturdy materials like steel, plastic, or aluminum. The hose winds around a central spindle, with operation possible via handle or crank for manual or automatic coiling.

To operate, simply turn the handle or activate the motor (for motorized models) to spin the drum. This action neatly coils the hose, preventing kinks and reducing wear. The hose can be smoothly extended when needed without twisting.

Available in various designs and sizes, hose reels accommodate everything from garden hoses to industrial models. They can be wall-mounted, portable, or vehicle-mounted, with some featuring automatic retraction or tension controls for enhanced convenience. Overall, hose reels significantly improve hose management and extend service life across multiple applications.

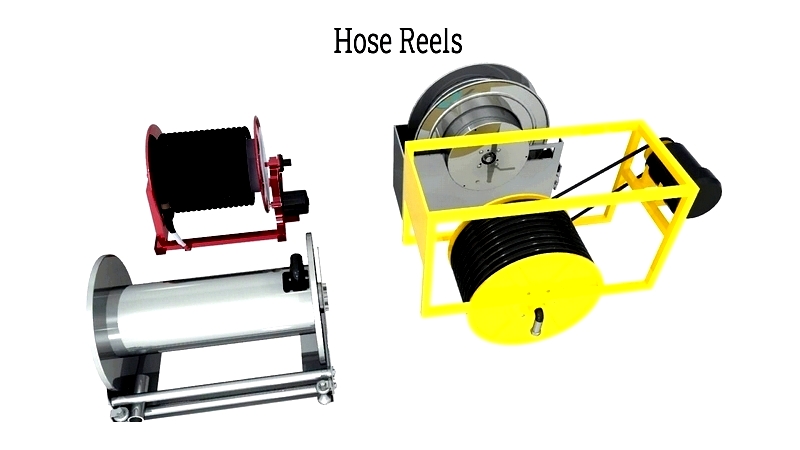

Chapter Two – Hose Reel Varieties

Hose reel designs vary widely to meet residential, commercial, and industrial needs. Home models are lightweight and compact, ideal for garden use and small outdoor spaces. Industrial versions feature robust construction with heavy-duty materials and safety features for demanding environments like manufacturing plants and fire stations.

Retraction options include manual cranks for light-duty use and spring-driven, electric, hydraulic, or pneumatic systems for heavy applications. Selection considerations include hose weight, pressure rating, length, diameter, and fluid type. Additional features like automatic guides and locking mechanisms enhance efficiency and safety.

Cable Hose Reel

Specialized for cable management in electrical and industrial settings, these reels feature durable steel or thermoplastic construction with spring rewind, motor-driven, or manual operation options. High-capacity models often include braking systems and cable guides to prevent tangling.

Power Cord Hose Reel

Designed for extension cord storage in construction sites and workshops, these reels accommodate cords from 30 to 250 feet. Mounting options include wall, portable, or caster-mounted designs with manual or automatic retraction.

Some models remain plugged in for controlled dispensing, while heavy-duty versions support industrial-grade cords with safety features like GFCI protection for OSHA compliance.

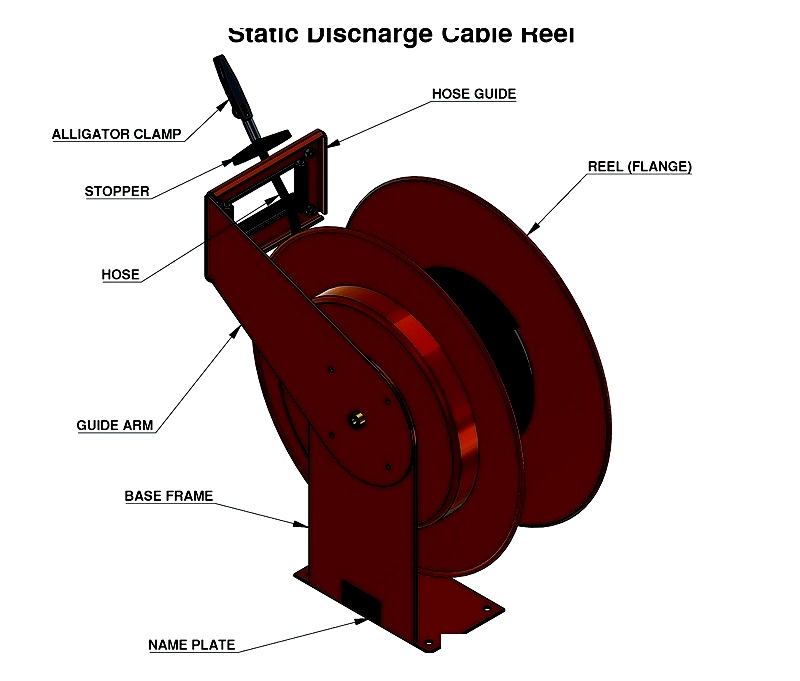

Static Discharge Hose Reel

Essential for static control in fueling and chemical operations, these corrosion-resistant reels feature conductive cables and discharge clamps to prevent sparking in volatile environments.

High Pressure Hose Reel

Engineered for pressures exceeding 3,000 PSI, these reinforced steel reels feature powder-coated frames and swivel joints for demanding applications like pressure washing and hydraulic systems.

Selection factors include hose diameter, length, pressure rating, and mounting style, with options for adjustable stops and locking mechanisms.

Air Hose Reel

Common in automotive and manufacturing settings, these reels connect to compressors and pneumatic tools, offering space-saving ceiling or wall mounting options.

Available as storage or continuous flow models, with features like spring retraction and automatic lockout for improved efficiency.

Audio Cable Reel

Essential for professional audio and video production, these durable reels handle long cable runs with integrated guides to prevent damage during rapid setup.

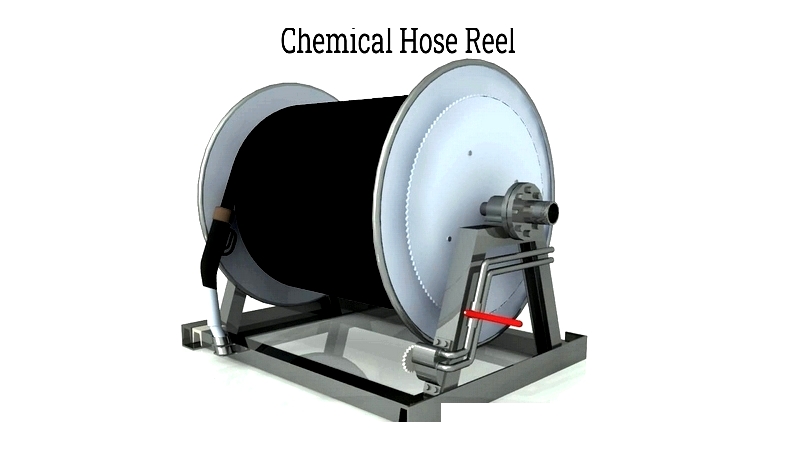

Chemical Hose Reel

Constructed from corrosion-resistant materials, these reels safely handle hazardous chemicals while meeting OSHA and EPA regulations.

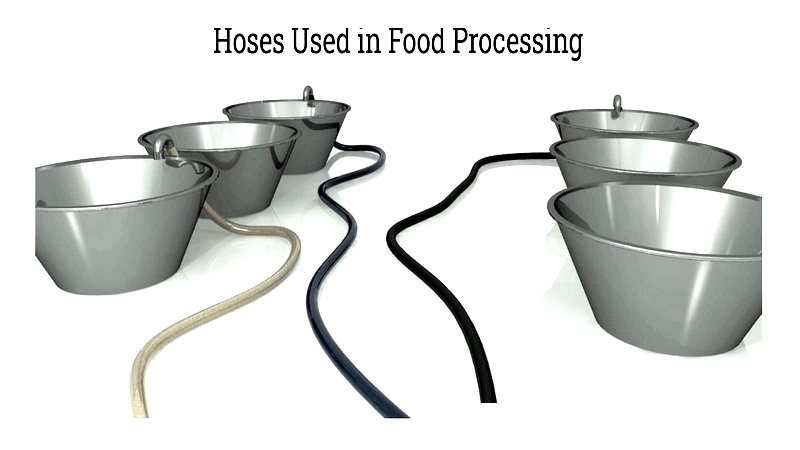

Beverage Hose Reel

Meeting food industry standards, these stainless steel reels feature sanitary designs for potable water and steam cleaning applications.

Common uses include ingredient transfer and equipment cleaning, with features like automatic shut-off valves for safety.

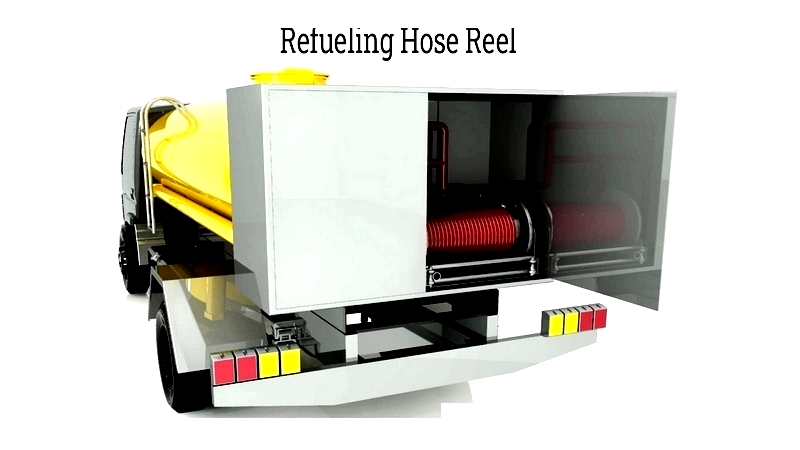

Fuel Hose Reel

Designed for petroleum products, these corrosion-resistant reels feature anti-static properties and explosion-proof components for safe fuel handling.

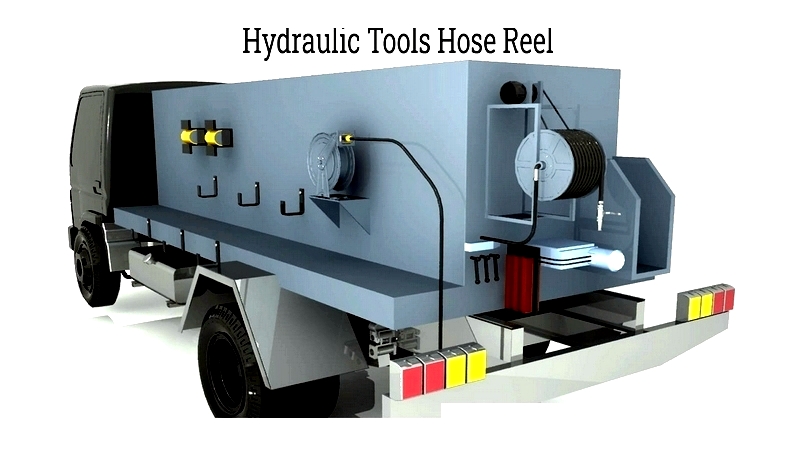

Hydraulic Tool Hose Reel

Built for fluid power applications, these reels withstand high pressures with features like abrasion-resistant guides and tension adjustment.

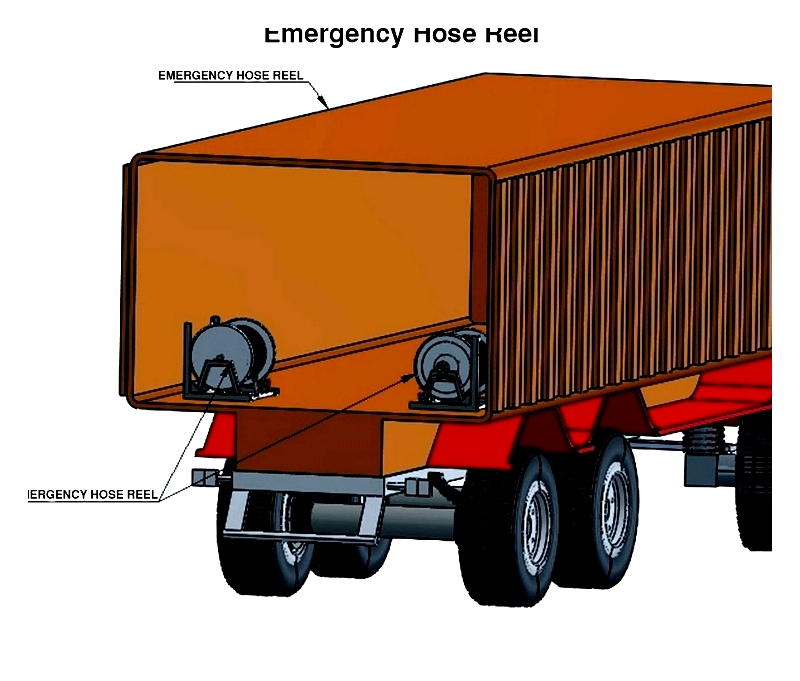

Emergency Hose Reel

Critical for firefighting and rescue operations, these durable reels feature quick-release mechanisms for rapid deployment.

Teach Pendant Hose Reels

Protecting expensive robotic cables, these reels prevent damage and entanglement in automated manufacturing environments.

Flat Hose Reel

Optimized for lay flat hoses, these reels offer