Introduction

This article provides an in-depth examination of solenoid coils.

You will explore topics including:

- What solenoid coils are

- Their manufacturing process

- Common applications

- Different types available

- And more...

Chapter One - What is a Solenoid Coil?

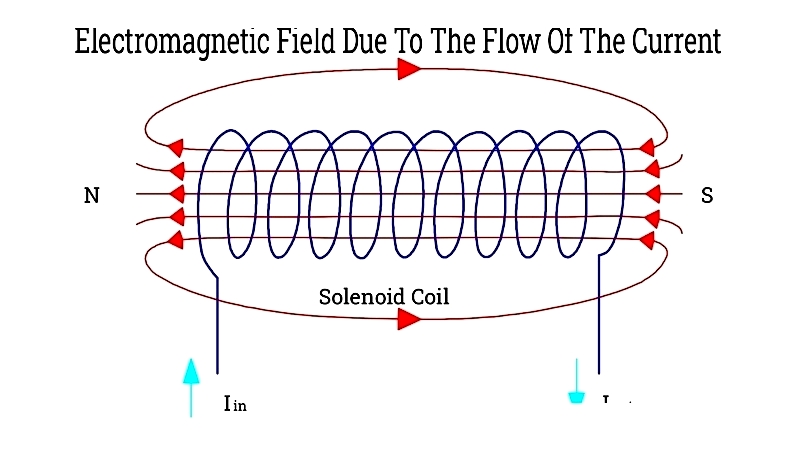

A solenoid coil is a common electrical component consisting of wire tightly wound around a metal core to produce an electromagnetic field. When current passes through the coil, it creates this field which enables linear motion. These coils represent one of the simplest forms of linear actuation devices.

Chapter Two - How Solenoid Coils are Used

Solenoid coils serve as versatile electromagnetic components essential across numerous industries, from industrial automation to consumer electronics. As key elements in solenoid actuators, their main purpose is to enable automatic switching, locking, or movement in electrical circuits and mechanical systems. When energized, the coil's magnetic field activates a movable armature to operate connected devices.

Their reliability and quick response make solenoid coils vital for automated and electromechanical systems. Industrial applications include hydraulic/pneumatic valves, robotics, automated gates, and precision control machinery. They're also crucial for safety interlocks, sorting machines, and process control systems requiring electrical-to-mechanical conversion.

Common Applications

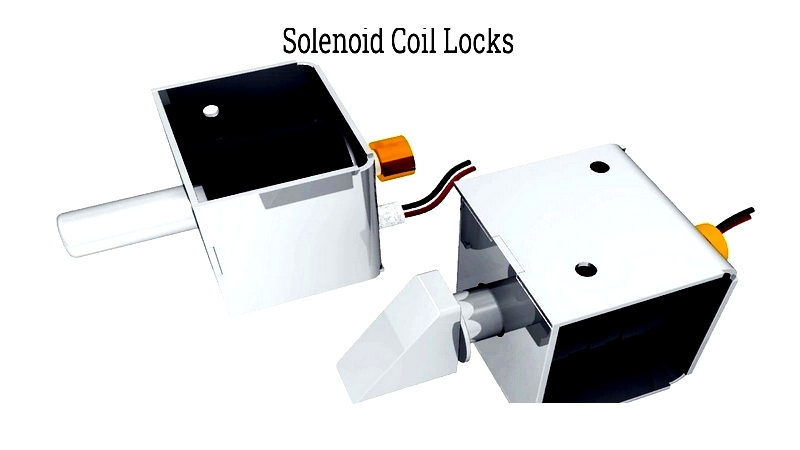

Locking Mechanisms

Solenoid coils power automatic locking systems in high-security areas. The coil stays inactive when locked; energizing it retracts the bolt for access. This failsafe design is essential for access control systems, safes, and smart security solutions requiring remote operation.

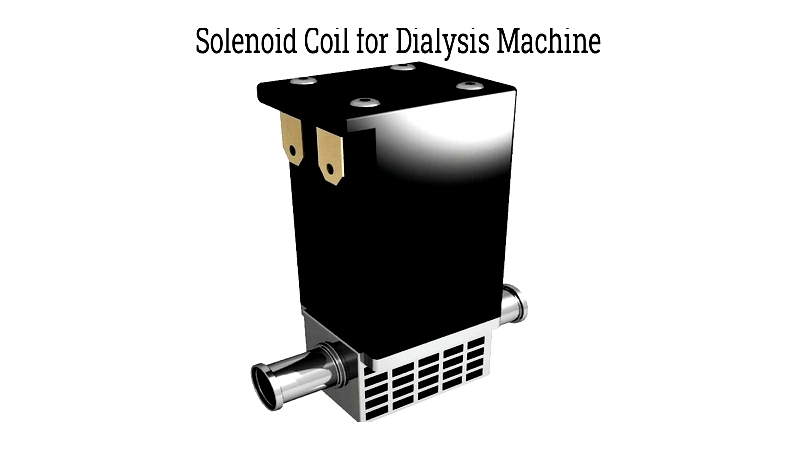

Medical Applications

In medical devices, solenoid coils provide reliable, precise actuation. They control fluid flow in dialysis machines and regulate medication dosing in dispensers. Other applications include oxygen therapy, diagnostic imaging, and infusion pumps. Medical-grade coils feature advanced materials and strict quality controls for safety and durability.

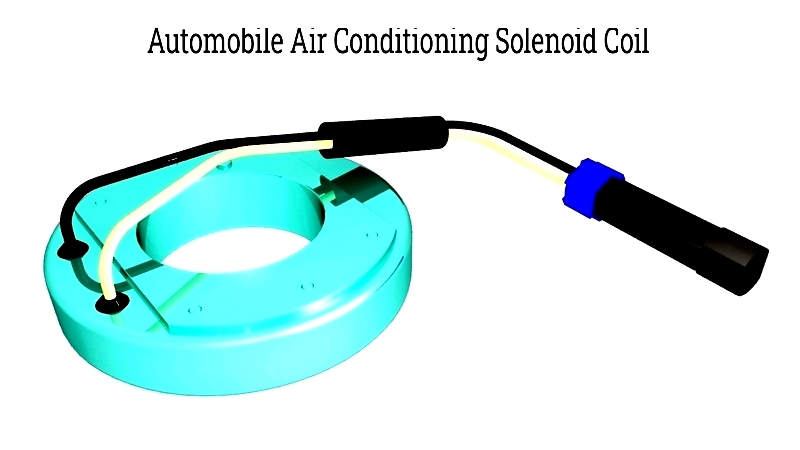

Automotive

Modern vehicles use solenoid coils in transmissions, starters, fuel injectors, ABS, and climate control systems. They enable keyless entry, gear selection, and infotainment features, contributing to vehicle safety, performance, and comfort.

Irrigation Systems

Solenoid coils automate water valves in agricultural and landscape irrigation. They enable remote control of water flow for efficient usage. Designed for outdoor use, these durable coils require proper filtration and maintenance to prevent clogging issues.

Aviation

Aircraft employ solenoid coils for power management and avionics protection. These high-performance coils isolate sensitive electronics during engine starts, meeting strict aerospace standards for vibration resistance and reliability.

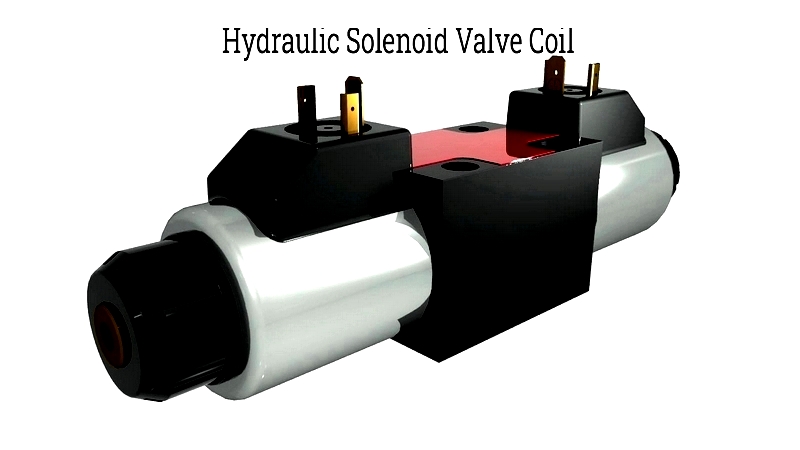

Hydraulic Systems

Hydraulic solenoid coils control fluid direction in heavy machinery and industrial equipment. They enable precise flow regulation for cylinders and actuators, with selection based on voltage, insulation, and duty cycle requirements.

Pneumatic Systems

Pneumatic solenoid coils operate valves in compressed air systems, enabling automation in packaging and manufacturing. Available in various configurations, these coils offer fast switching and reliable performance under different pressure conditions.

Pinball Machines

Pinball machines use solenoid coils to power flippers and bumpers. These coils provide quick, forceful actuation for dynamic gameplay, with modern designs incorporating safety features to prevent overheating and ensure consistent performance.