Introduction

This section explains process chillers and their applications, along with a list of manufacturers.

You will learn about:

- What is a Process Chiller?

- Types of Process Chillers

- Applications of Process Chillers

- How Process Chillers Work

- And much more...

Chapter 1: What is a Process Chiller?

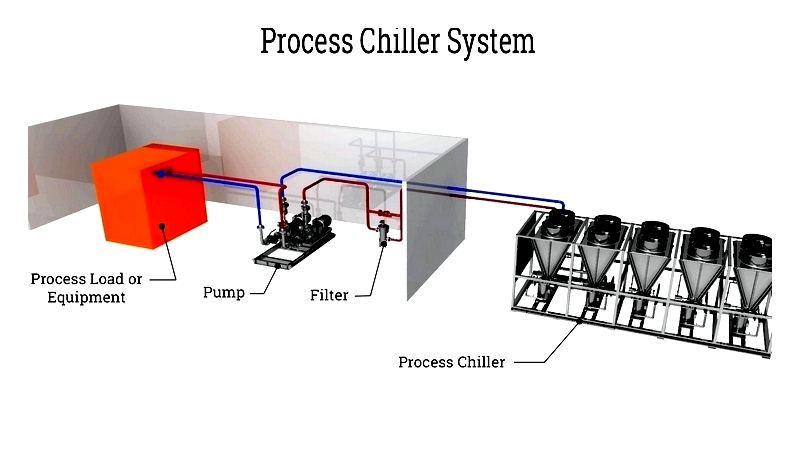

A process chiller is a cooling system that circulates water to remove heat from industrial processes. Using a closed-loop system, it transfers heat from circulating water to a refrigerant. Process chillers are widely used due to their high efficiency and reliability in heat removal during manufacturing. This heat removal protects equipment and products while ensuring optimal performance and extending equipment lifespan.

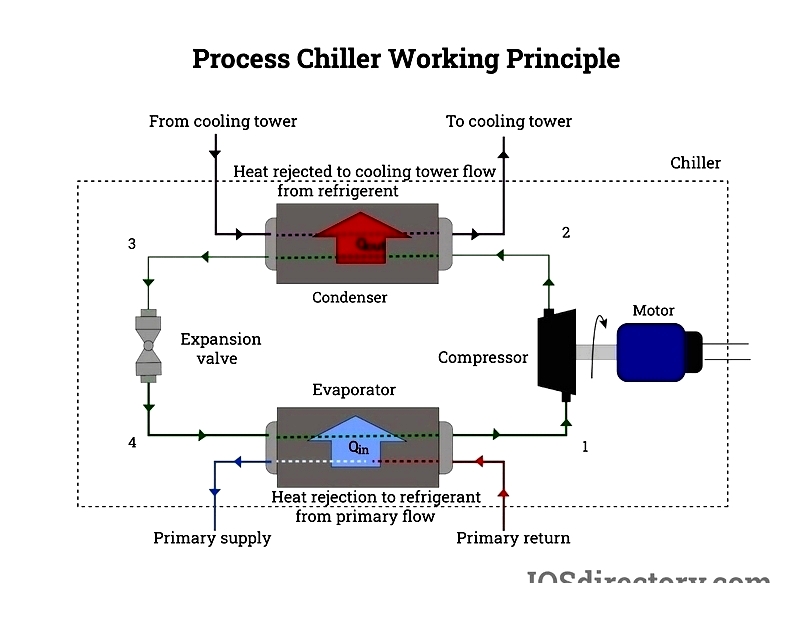

A typical process chiller operates with a pumping system that circulates cooling water or glycol solution. As the fluid flows through equipment, it absorbs heat and returns to the chiller, where the heat transfers from the fluid to refrigerant. The refrigerant then carries the heat through a compressor, condenser, and evaporator to complete the heat removal process.

The refrigerant type varies depending on the required process temperature. It undergoes phase changes from liquid to gas and back to liquid. All process chillers contain basic components for refrigerant handling: a compressor, evaporator, condenser, and expansion valve - essential for the closed-loop cycle.

Chapter 2: Types of Process Chillers

Process chillers are primarily classified as water-cooled or air-cooled, based on their heat dissipation methods. They are further categorized by compressor type: screw, scroll, or reciprocating. Each type serves specific applications and industries, offering customized cooling solutions. These systems feature complex designs to cool equipment, spaces, and maintain optimal temperatures for operational efficiency.

Types of Compressors

Chillers fall into two main classes: water-cooled and air-cooled, differing in how they expel collected heat. Both types are further distinguished by their compressor technology, which uses different methods to compress the heat-carrying refrigerant.

Compression methods include positive displacement and dynamic, used in both residential HVAC systems and industrial chillers. Compressors are crucial as they determine a chiller's heat processing capability and overall capacity.

- Positive Displacement Compressors – These compress vaporized refrigerant into a smaller volume at higher pressure, delivering refrigerant gas efficiently at constant speed.

- Dynamic Compressors – These use rotating impellers to generate kinetic energy, reducing refrigerant volume while increasing pressure.

Engineers select compression methods based on factors like required temperature, refrigerant volume, and chiller capacity.

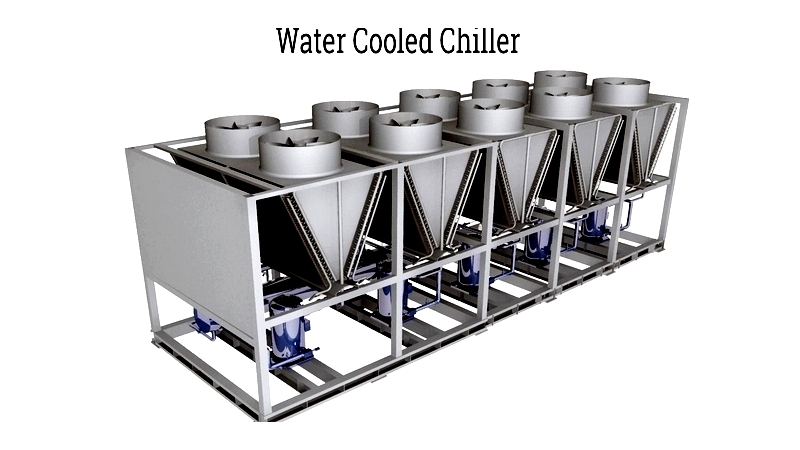

Water Cooled Process Chiller

Water-cooled chillers use water to collect process heat and transfer it to refrigerant. The chilled water exits at 6°C (42.8°F) and is pumped through equipment, absorbing heat before returning to the chiller. The refrigerant then carries this heat through the condenser, where a water loop connected to a cooling tower releases it into the atmosphere.

Heat transfer occurs through pipe walls in the condenser. Cooling towers use fans to dissipate heat, with cooled water returning to continue the cycle. Tower designs include cross flow, counter flow, natural draft, and mechanical draft.

Air Cooled Chiller

Air-cooled chillers operate similarly but without pumps or cooling towers. Water circulates between chiller and equipment, with refrigerant carrying heat to condenser tubes where powerful fans dissipate it. Their simpler design makes them affordable and easy to install, suitable for outdoor placement in various environments.

These chillers offer substantial cooling capacity for demanding industrial applications while requiring less water than water-cooled systems.

Scroll Chillers

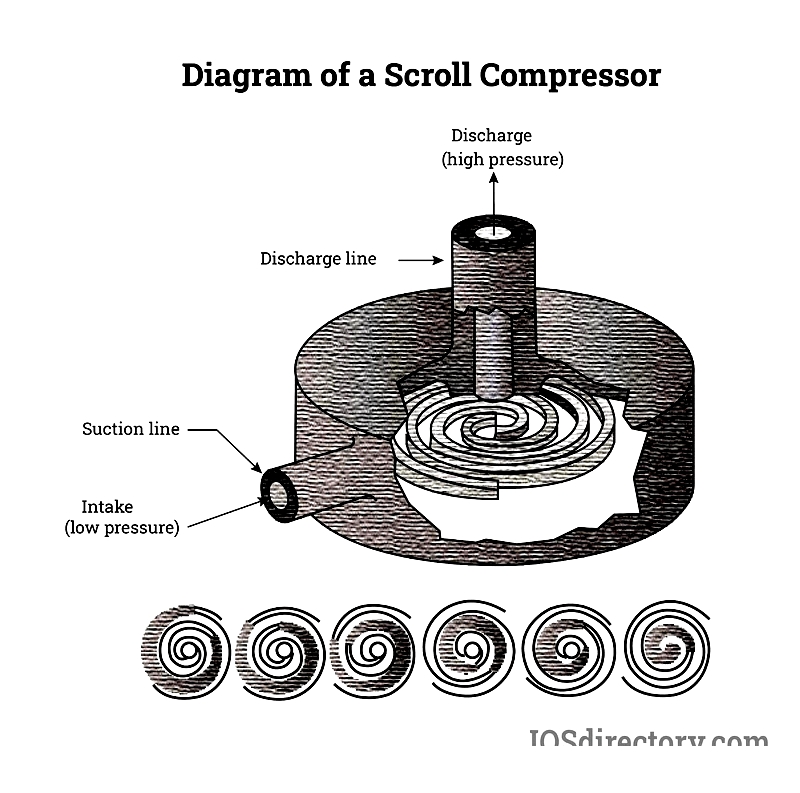

Scroll chillers feature unique compression using two interleaving scrolls - one stationary, one orbiting. This creates pockets that compress refrigerant gas before sending it to the condenser. They operate more quietly than reciprocating chillers but cost more, appearing in both air and water-cooled systems.

Their design reduces breakdown risk, lowering maintenance costs while offering higher efficiency and capacity than reciprocating models.

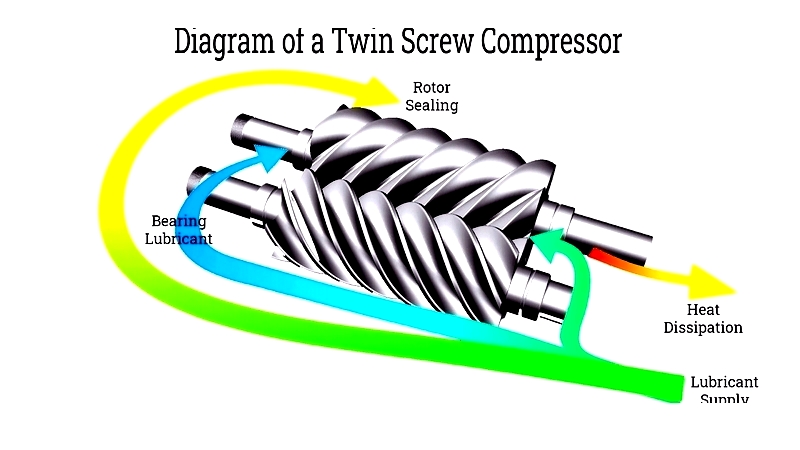

Screw Chiller

Screw chillers feature helical compressors with slotted rotors that compress refrigerant through volume reduction. The refrigerant transforms from liquid to gas vapor as it moves linearly through the compressor. These chillers offer 30-400+ ton capacity, exceeding scroll chiller capacity, and may use single or dual screws for enhanced efficiency.

Explosion Proof Chillers

These specialized chillers withstand explosive environments using protective materials. Available in air or water-cooled versions with various compressor types, their explosion-proof rating comes from system design meeting NEC standards for hazardous locations containing flammable materials.

Key industries using them include oil/gas, chemical processing, and mining, where they contain potential explosions within their structure to protect personnel and assets.

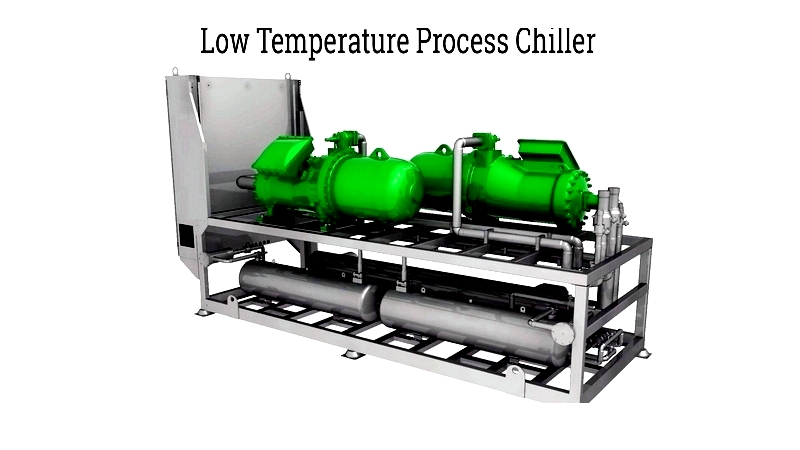

Low Temperature Chillers

Designed for extreme cooling (0°C to -31.67°C), these chillers use multiple refrigeration stages with different refrigerants. Their robust components withstand demanding temperatures, utilizing specialized heat transfer fluids like silicone oil or fluorinated compounds.

Available in air or water-cooled versions, they feature stronger compressors, valves, tubing, and condensers than standard chillers.

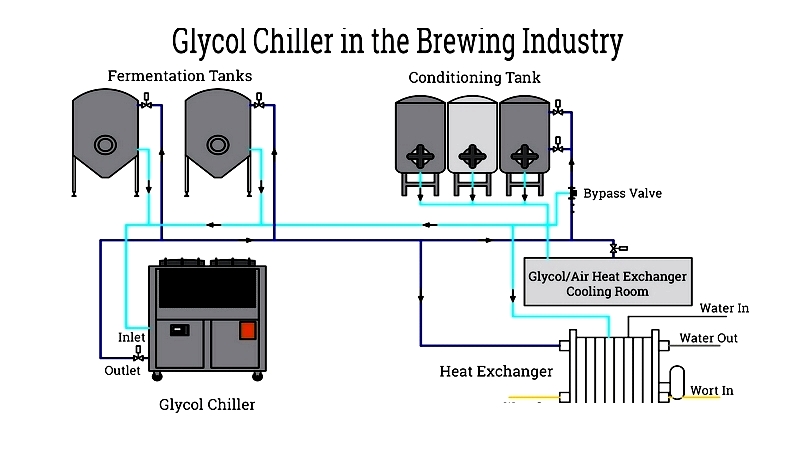

Glycol Chillers

These use glycol-water mixtures (typically 60/40) as coolant, offering antifreeze properties for rapid cooling. Ethylene glycol suits non-food applications, while non-toxic polyethylene glycol works in food production, breweries, and dairies.

Glycol chillers provide consistent temperatures (±1° variation), making them ideal for food quality maintenance. USP standards guide appropriate glycol selection.

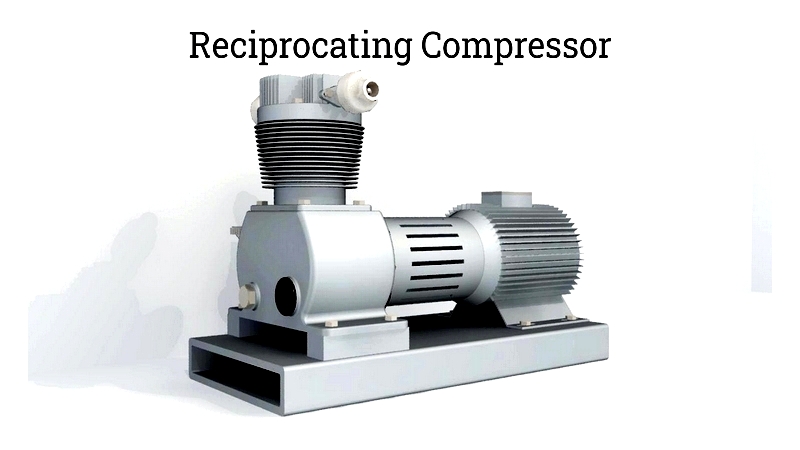

Reciprocating Chillers

These older-style chillers use piston compressors for positive displacement. The piston creates vacuum to intake refrigerant, then compresses it before discharge. Types include hermetic, semi-hermetic (both non-serviceable), and direct-drive models, with limited use in high-volume applications today.

All described chiller types feature durable designs for industrial environments, with compressors being their most critical component. Their reliability is essential to prevent process disruptions in demanding applications.