Introduction

This article provides information about ceramic insulators and their applications.

You will learn about:

- What ceramic insulators are

- How ceramic insulators are used

- Different types of ceramic insulators

- The manufacturing process of ceramic insulators

- And more...

Chapter One: What is a Ceramic Insulator?

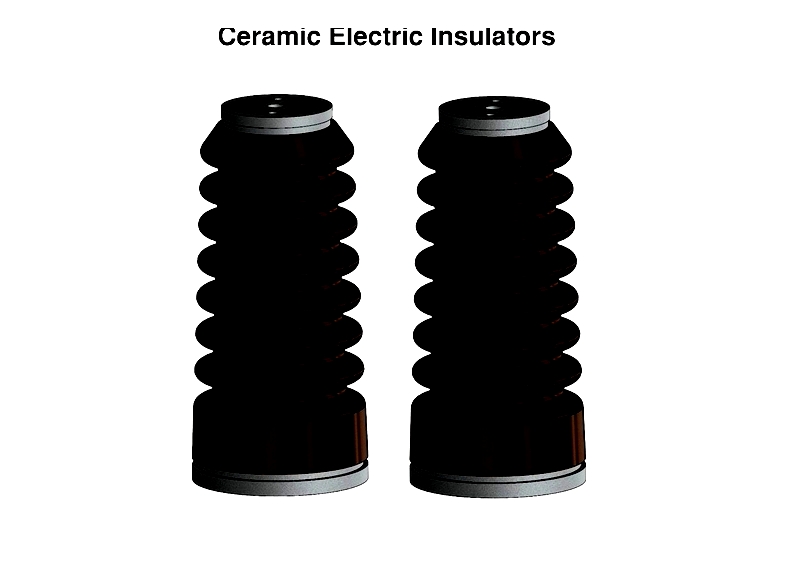

Ceramic insulators are insulating materials made from clay that can be red, brown, or white, typically featuring a porous texture. These insulators effectively separate electronic components while providing excellent dielectric properties, including high resistance to electrical currents and minimal energy loss. They are easy to maintain and highly resistant to stains and residue buildup. Ceramics have long been preferred for electrical insulation due to their exceptional ability to withstand electrical stress.

Ceramic insulators gained widespread popularity in the 1950s because of their affordability and durability in various weather conditions. By the 1970s, they had completely replaced glass insulators, which ceased production in the 1960s. Although some glass insulators remain in use today, they represent only a small fraction compared to the dominant ceramic insulators.

Chapter Two: How Ceramic Insulators are Used

Ceramic insulators play a vital role in numerous electrical and electronic applications, from high-voltage power transmission systems to compact mobile devices. As one of the most reliable electrical insulation materials, they are chosen for their superior dielectric strength, mechanical durability, and resistance to heat and weather. Commonly used in power lines, coaxial cables, substation equipment, transformers, and printed circuit boards, they help prevent electrical hazards such as electromagnetic interference (EMI), arcing, fires, power surges, and short circuits.

These high-performance insulators also withstand extreme environmental conditions, resist contamination and corrosion, and maintain their insulating properties over long periods with minimal maintenance. Their thermal resistance, customizable shapes, and compliance with industry standards make them essential for improving the reliability, safety, and efficiency of electrical infrastructure. In both industrial and consumer electronics, ceramic insulators ensure system stability, prevent current leakage, and extend equipment lifespan, making them indispensable in modern electrical engineering and power distribution.

Uses for Ceramic Insulators

Wire Support

Ceramic insulators are widely used as wire supports on utility poles, transmission towers, and telecommunication masts, making them crucial for power grids and communication networks. Their umbrella-like shape effectively diverts water and moisture, reducing the risk of current leakage during rain, sleet, or snow. Also known as pin or line post insulators, they are designed to endure long-term exposure to UV radiation, mechanical vibrations, and temperature fluctuations. Their robust design and high creepage distance minimize flashover and surface contamination, ensuring reliable power delivery over long distances.

Mechanical Tension

Mechanical tension ceramic insulators, or strain insulators, are designed to withstand the pulling forces of overhead conductors. Used in high-voltage transmission lines, radio antenna guy wires, and distribution networks, they maintain secure line alignment and prevent conductor sag. These insulators ensure electrical clearance between live wires and supports, preserving circuit integrity and reducing wear on conductors and hardware. Their ability to absorb mechanical shock enhances the safety and reliability of power and telecommunications infrastructure.

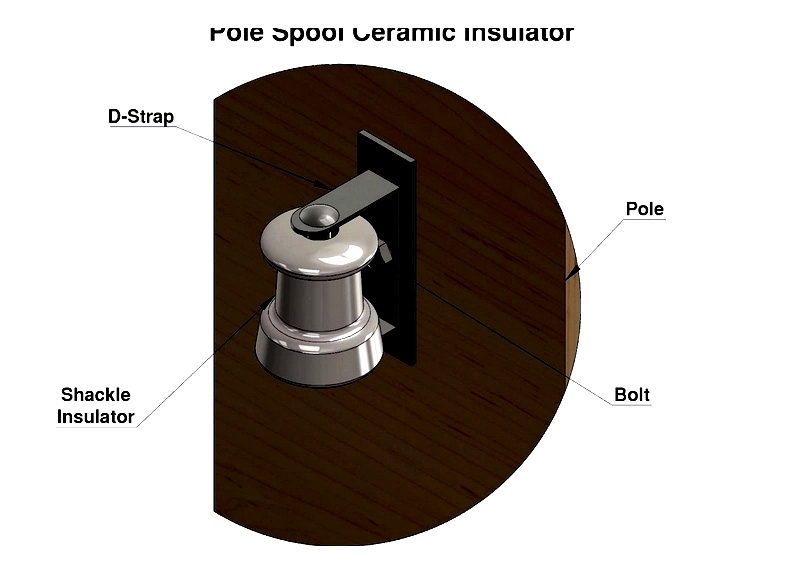

Pole

Pole ceramic insulators, or spool insulators, are compact components mounted on brackets or cross arms to support wiring on utility poles and substations. A central rod or bolt secures them, accommodating wire angle changes. Commonly used in distribution networks and rural electrification, they provide excellent electrical isolation and flexible installation, even in challenging terrain. Their design is particularly suitable for corner or angle poles where directional changes require stable wire positioning.

Safety

Safety ceramic insulators act as barriers against unwanted current flow, protecting personnel and equipment. When wires are damaged during storms or accidents, these insulators prevent dangerous current from reaching the ground or structures. Their robust construction and high dielectric strength are crucial for overhead power distribution, railway systems, and urban infrastructure. Different configurations meet various safety requirements and voltage levels, ensuring compliance with electrical codes.

In cases of pole collapse or wire breakage, ceramic safety insulators isolate faulty sections, reducing the risk of shock, property damage, and service interruptions. They are essential for modern electrical grid protection.

Low Voltage Distribution

Low voltage distribution ceramic insulators provide effective insulation for utility networks and building wiring systems. Installed on cross arms, wall mounts, or poles, they offer excellent electrical resistance and mechanical stability. These insulators are important for municipal power distribution, commercial installations, and renewable energy systems like solar and wind power. By minimizing current leakage, they help deliver safe, stable energy to homes and businesses.

Their cost-effectiveness, reliability, and low maintenance make them a top choice for utility companies prioritizing safety and system uptime.

Spark Plugs

Ceramic insulators are critical in automotive and industrial spark plugs, acting as dielectric barriers between electrodes and metal shells. They channel high-voltage arcs to ignite fuel-air mixtures in engines, with materials like alumina providing heat shock resistance and electrical isolation. Their low thermal expansion ensures consistent performance under extreme combustion chamber conditions, meeting the demands of modern automotive, aerospace, and power generation industries.

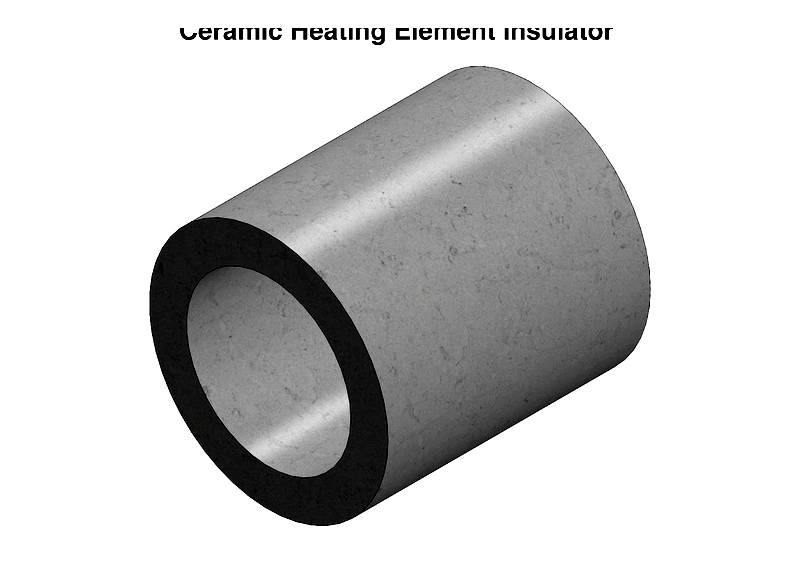

Heat Applications

Ceramic insulators are ideal for high-temperature environments, providing support and electrical isolation in industrial ovens, heaters, and furnaces. Their resistance to thermal shock, abrasion, and chemicals ensures long service life under cyclical loads. Used in electric furnaces, kilns, laboratory equipment, and appliances, they enhance energy efficiency and safety by maintaining temperature control and preventing electrical faults.

Technical ceramics like alumina and zirconia are widely used in advanced heat management systems and industrial processes due to their non-conductive and inert properties.

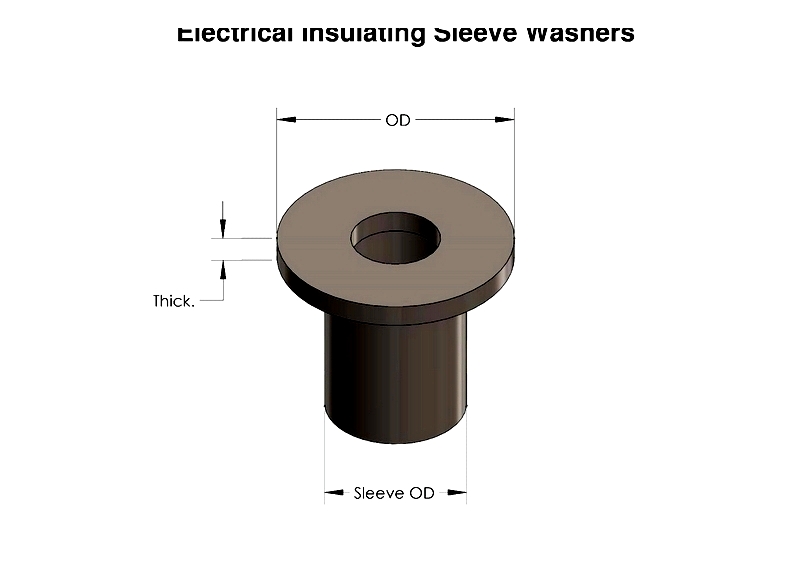

Sleeve Washers

Ceramic sleeve washers, or insulating washers, prevent current bypass and galvanic corrosion at fastener junctions. Used in circuitry, instrumentation, and electronics, they withstand extreme temperatures and corrosive gases. Common in power electronics, transformers, and aerospace hardware, they improve dielectric spacing and durability in harsh environments. Custom configurations make them a reliable choice for engineers seeking robust electrical insulation.