Introduction

This article provides an in-depth exploration of friction hinges and their applications.

We will cover the following topics:

- Key Features of Friction Hinges

- Mechanical Operation of Friction Hinges

- Different Types of Friction Hinges

Chapter 1: What is a Friction Hinge?

A friction hinge provides resistance to rotational movement, allowing controlled positioning of components during opening and closing operations. Also called free motion, positioning, torque, or free stop hinges, they maintain precise mechanical tolerances.

These hinges generate torque through applied force, with additional resistance created by lubricants or springs. Typically installed on both sides of doors or windows, they enable stable positioning without requiring full opening or closing.

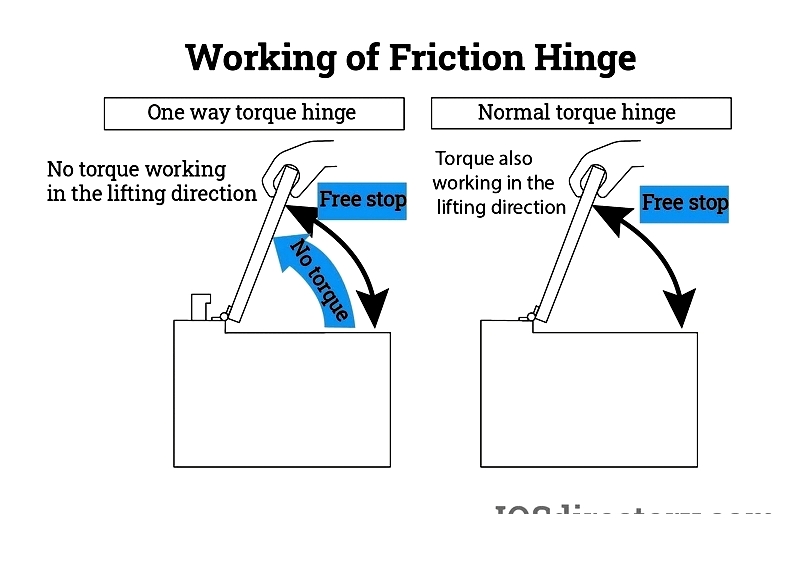

Designed for long-term positioning, friction hinges can be customized as one-way or two-way variants. One-way models resist movement in a single direction, while two-way versions control motion in both directions. Some designs combine both resistance types with adjustable viscosity, temperature tolerance, and torque characteristics.

Practical and secure, friction hinges are ideal for machinery applications. Some models incorporate features like lift assistance to reduce operational effort.

Friction Hinge Strength Variations

Torque strength varies depending on hinge type, design, and internal construction. Each model typically specifies a torque range with ± tolerance values. Understanding these specifications is crucial for optimal performance.

For best results, torque strength should remain near the lower end of the specified range. Excessive torque may prevent free positioning, while insufficient torque can make components difficult to adjust.

Chapter 2: Materials Used in Friction Hinges

Friction hinges are precision components that control movement in various applications. Manufactured from durable metals, material selection directly impacts performance, longevity, and suitability for specific environments.

Different metals offer unique combinations of strength, corrosion resistance, and machinability. These properties are particularly important for hinges supporting moving components weighing 1-10 pounds (0.45-4.5 kg).

Key material considerations include:

- metal capabilities

- Physical properties

- Corrosion resistance

- Mechanical strength

- Surface finish

Common materials include cold rolled steel, stainless steel, aluminum, bronze, and brass, each suited to different applications from residential to aerospace environments.

Cold Rolled Steel Hinges

Processed at room temperature, cold rolled steel offers excellent strength and surface finish. These hinges require protective coatings for humid environments but are ideal for heavy-duty industrial applications.

Stainless Steel Hinges

Stainless steel's chromium content creates a protective oxide layer, making it resistant to corrosion. Common grades include:

- Grade 316: Superior corrosion resistance with molybdenum content, ideal for marine environments

- Grade 18-8: Standard austenitic steel with 18% chromium and 8% nickel, offering good corrosion resistance and appearance

Stainless steel is preferred for food-grade, medical, and marine applications due to its durability and low maintenance.

Aluminum Hinges

Aluminum combines light weight with strength, making it suitable for mobile devices and aerospace applications. Anodized or powder-coated finishes enhance durability.

Brass Alloy Hinges

Brass (67% copper, 33% zinc) offers corrosion resistance and antimicrobial properties, ideal for marine and healthcare applications.

Bronze Hinges

Bronze provides excellent wear resistance and aesthetics, commonly used in outdoor and historical installations.

Steel Hinges

Steel offers cost-effective strength for general applications. Variants include:

- Hot Rolled Steel: More ductile but less strong than cold rolled

- Galvanized Steel: Zinc-coated for enhanced corrosion resistance

Titanium Hinges

Titanium combines high strength with light weight and corrosion resistance, making it ideal for aerospace and medical applications despite higher costs.

Material Selection Guide

Consider application requirements, environmental conditions, load capacity, aesthetics, and budget when selecting hinge materials. Consult manufacturers for technical specifications to ensure optimal performance and longevity.