Introduction

This article provides information about forging presses and their applications.

You will learn about:

- What is a Forging Press?

- The Forging Press Process

- Advantages of Forging Presses

- metals Used in Forging Presses

- And much more...

Chapter One – What is a Forging Press?

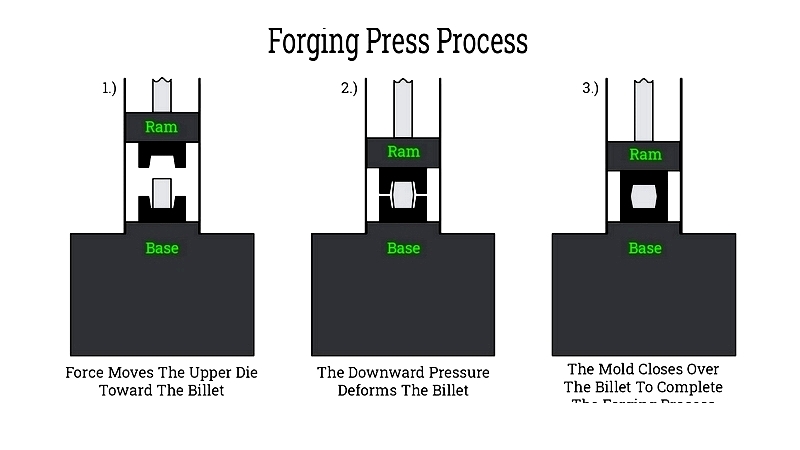

A forging press operates by using a vertical ram to apply controlled pressure on a die containing a workpiece. Unlike drop forging which uses repeated strikes, this method employs continuous pressure. The ram's steady movement allows deeper material penetration, ensuring uniform plastic deformation.

Forging presses use two main die types: open and closed. Open dies partially surround the workpiece, permitting some movement, while closed dies (impression dies) fully enclose the material.

These presses generate force through either hydraulic or mechanical systems. Mechanical presses utilize a flywheel and crank mechanism to drive the ram, capable of producing up to 12,000 tons of pressure. Hydraulic presses, powered by high-pressure fluid, can deliver up to 75,000 tons of force for more demanding applications.

The variety of forging presses is determined by their size and the force required to achieve proper plastic deformation in workpieces.

Chapter Two – Types of Forging Presses

Modern forging operations rely on machines that generate substantial force for metal forming. These high-performance presses produce precise tolerances and shapes for industries like automotive, aerospace, and heavy machinery. They operate using open or closed dies and are classified by their force-generation methods: mechanical, hydraulic, screw, servo, pneumatic, and upsetters.

Presses also differ by frame design: straight-sided for high-tonnage operations and C-frame for easier access in smaller-scale work.

Basic mechanical presses use a vertical ram to shape workpieces with dies. Modern versions represent significant advancements over traditional hammer methods, offering automated, high-speed operation for consistent quality. Other types include hydraulic, screw, servo, pneumatic, and upsetters, each capable of forging strong metals and alloys.

Hydraulic Forging Presses

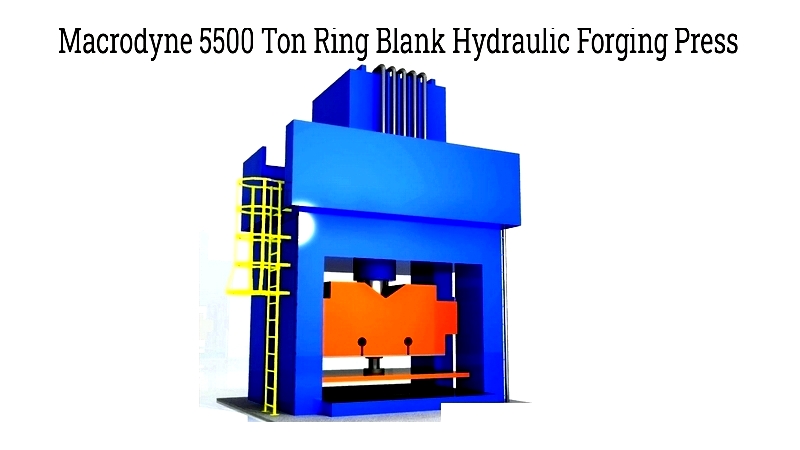

Hydraulic presses generate force using fluid mechanics (Pascal's Law). A small initial force on hydraulic fluid creates significant pressure to operate the ram. These slower-operating presses are ideal for high-strength alloys and precision components, commonly using open dies for complex shapes. Advanced models handle up to 50,000 tons with large die beds for producing items like crankshafts and turbine discs.

Hydraulic Press Components

- Safety Door: Protects operators during operation

- Limit Switch: Prevents mechanical over-travel

- Manual Control Valve: Allows precise fluid control

- Relief Valve: Manages maximum system pressure

- Pressure Gauge: Monitors system pressure

- Hydraulic Cylinder: Powers the ram movement

- Oil Tank: Stores hydraulic fluid

- Pressing Plate: Ensures even workpiece deformation

Mechanical Forging Presses

These presses use a motor-driven crankshaft assembly to deliver fixed stroke cycles. The ram reaches maximum speed mid-stroke, making them ideal for high-volume production of small to medium parts. Modern automated versions achieve up to 70 strokes per minute, reducing labor costs and increasing throughput for items like automotive components.

Mechanical Press Components

- Motor: Primary power source

- Ram: Transmits force to the die

- Die: Forms the workpiece cavity

- Anvil: Supports the lower die

- Bailing Compartment: Holds heated workpieces

Chapter Three – Advantages of Forging Presses

Forging presses offer superior efficiency, reliability, and product quality compared to other metalworking methods. The process enhances grain flow, improving mechanical properties and fatigue resistance. Forged parts feature continuous grain structures that follow component geometry, eliminating weak points and ensuring exceptional structural integrity.

Key Advantages

Strength-to-Weight Ratio

Forging aligns grain structure to distribute stress effectively, creating strong yet lightweight components critical for aerospace and automotive applications.

Reduced Defects

The process minimizes porosity and voids, producing dense, defect-free metal structures that require less finishing.

Cost Efficiency

Forging maximizes material use, reduces waste, and minimizes secondary operations, lowering overall manufacturing costs.

High Productivity

Presses support high-volume production with short cycle times, capable of making 40-50 parts per minute.

Complex Designs

Advanced die technology allows intricate shapes with tight tolerances and deep draws up to six times material thickness.

Chapter Four – metals for Forging Presses

Press forging works with various metals including carbon steel, stainless steel, aluminum, titanium, brass, and copper. Selection depends on required strength, durability, and weight characteristics.

Common Forging metals

Steel

Heated to 2200°F (1200°C) for forging, steel becomes highly malleable without cracking risk.

Aluminum

Lightweight and corrosion-resistant, aluminum offers design flexibility and doesn't require preheating.

Titanium

Known for excellent strength-to-weight ratio and corrosion resistance, titanium is heat-treated before forging.

Chapter Five – Forging Press Limitations

While offering many benefits, press forging has some drawbacks to consider.

Main Disadvantages

Cost

The large, specialized equipment represents a significant investment.