Introduction

This article provides comprehensive information about Ball Valves.

You'll learn about:

- What a ball valve is and how it works

- Ball valve components

- Different types of ball valves

- Construction materials used in ball valves

- Advantages and limitations of ball valves

- And more...

Chapter 1: What is a Ball Valve and How Does It Work?

A ball valve is a type of shut-off valve that regulates the flow of gases, liquids, and vapors in piping systems. It operates by rotating a ball with a central bore that either permits or blocks flow. Positioned between two seats and connected to an operating mechanism via a shaft, the valve stops fluid passage when the bore is perpendicular to the flow direction. When aligned with the flow, it allows fluid to pass through, with the flow rate determined by the exposed bore area.

As quarter-turn valves, ball valves share this classification with plug valves and butterfly valves. They can be operated manually or with actuators. The simplest operation involves using a wrench or lever that's manually turned. Applying torque rotates the lever arm 90 degrees in either direction to open or close the valve. A lever parallel to the pipe indicates an open valve, while a perpendicular lever shows a closed valve.

Ball valves come in numerous designs with various features to meet diverse industrial needs. Their standards and specifications vary according to industry applications.

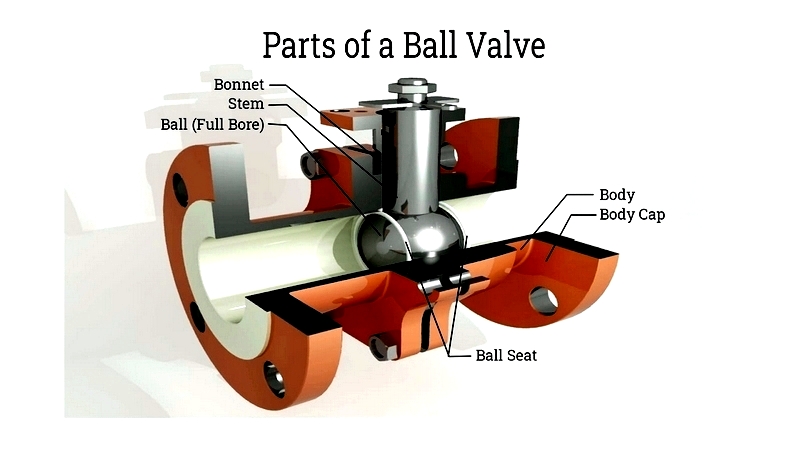

Chapter 2: Ball Valve Components

Ball valves play a crucial role in flow control systems, offering reliable shut-off capabilities across industries like oil and gas, petrochemicals, water treatment, HVAC, and manufacturing. Comprising essential internal and external components, each part is designed to optimize performance, durability, and fluid isolation. Understanding these components is fundamental for selecting, operating, and maintaining valves in both manual and automated systems.

Valve Housing

The valve housing, or body, encloses all internal components, providing a sealed environment for the ball. It features inlet and outlet ports for pipe connections and is typically made from durable metals, thermoplastics, or lined metals. Available in one-piece, two-piece, or three-piece designs, each offers unique maintenance and application benefits.

Ball

The spherical component features a central bore that controls flow. Solid balls maintain consistent flow, while hollow balls allow higher rates but may cause turbulence. Designs include full port and reduced port options, affecting flow efficiency and pressure drop.

Shaft

This component connects the ball to the control mechanism, enabling rotation. Equipped with sealing elements like O-rings, the shaft must withstand system pressures and temperatures. It can be manually operated or actuated electrically, pneumatically, or hydraulically.

Bonnet

Extending from the valve housing, the bonnet encases the shaft and packing, particularly in high-pressure/temperature applications. Constructed from sturdy metal, it may be welded or bolted and sometimes features safety enhancements like blowout-proof designs.

Seat

Typically made from PTFE or elastomers, the two seats create tight seals around the ball. The upstream seat seals against pressure, while the downstream seat prevents atmospheric leakage. High-performance applications may use reinforced materials like PEEK or metal.

Seals, Gaskets, and Packing

These components prevent leakage using materials like PTFE, rubber, or graphite. Stem packing minimizes emissions, ensuring compliance with safety and environmental standards.

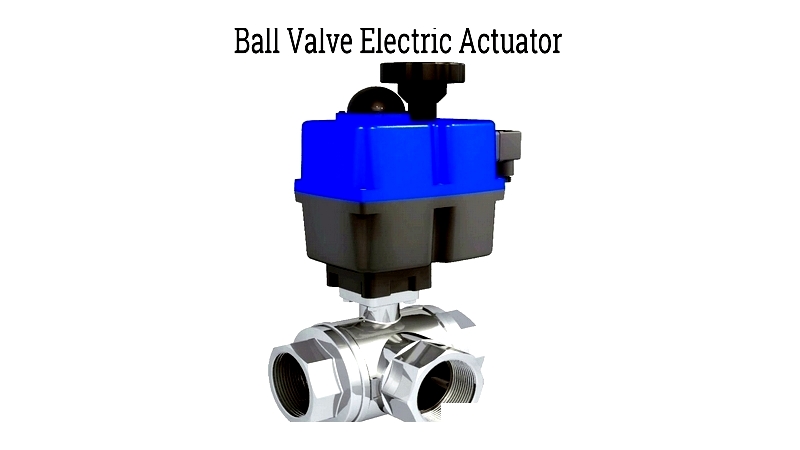

Electric Actuator

Electric actuators enable remote valve control, available in quarter-turn or multi-turn designs. The motor-driven gear system connects to the valve, housed in a waterproof enclosure. Features may include adjustable cycles and network connectivity.

While pneumatic actuators use compressed air, electric actuators offer greater versatility despite higher costs. Selection depends on torque requirements, cycle frequency, and system integration needs.

Motorized Ball Valves

These automated valves use electric actuators for precise flow control, often integrated with PLC systems. Position sensors and microprocessors enable accurate valve positioning, with communication options like 4-20 mA or Modbus protocols.

Ideal for remote locations, they're widely used in HVAC, water treatment, and chemical processing where reliability and quick response are essential.

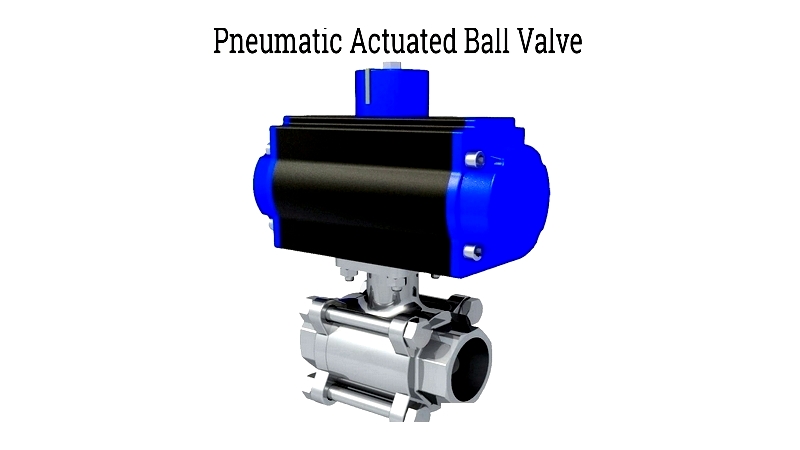

Pneumatic Actuated Ball Valves

Using compressed air, these actuators convert linear piston motion into rotary action. Their simple, reliable design makes them cost-effective for hazardous environments where electricity isn't suitable.

Common in food processing and pharmaceuticals, they offer fast operation with fail-safe options and can include positioners and speed controls.

Additional Accessories

Valves may include lockout devices, emergency shutoffs, fire-safe certification, or heating jackets. Proper selection of materials and accessories ensures optimal performance and compliance with industry standards.