Introduction

This article covers everything you need to know about vertical conveyors and their applications.

You will learn about:

- What vertical conveyors are

- Different types of vertical conveyors

- Common uses for vertical conveyors

- Key benefits of vertical conveyors

- And much more...

Chapter 1: What Is a Vertical Conveyor?

A vertical conveyor system is a mechanical solution designed to move items like goods, products, and components between different height levels. It improves efficiency by saving time and reducing physical effort, transporting materials to accessible locations whether moving upward or downward.

Often called vertical reciprocating conveyors (VRCs), these systems are customized to meet various size, space, and lifting requirements across multiple applications. Since their introduction in the mid-20th century, vertical conveyors have become essential in material handling and supply chain management.

Vertical Reciprocating Conveyors (VRCs) are classified as material handling equipment under the ASME B20.1 safety code standards. They are engineered for vertical material movement between floors or levels, offering a secure and efficient alternative to elevators or manual handling. VRCs are particularly useful for transporting items from basements, mezzanines, or within multi-story facilities, often proving more cost-effective than other elevation solutions.

Chapter 2: Types of Vertical Conveyors

Vertical conveyors, also known as vertical reciprocating conveyors (VRCs) or vertical lift conveyors, include diverse solutions for modern material handling and automation. These systems efficiently move products, goods, and bulk materials between floors or facility levels. With various designs and configurations, they can be tailored to meet specific industry needs, such as transporting cement bags, heavy pallets, or packages in fulfillment centers.

While some vertical conveyors used on construction sites may appear simple, most systems are custom-engineered to optimize workflow efficiency. They are widely used in airport baggage handling, automated storage systems, food processing plants, e-commerce distribution, and pharmaceutical manufacturing, where controlled movement is crucial.

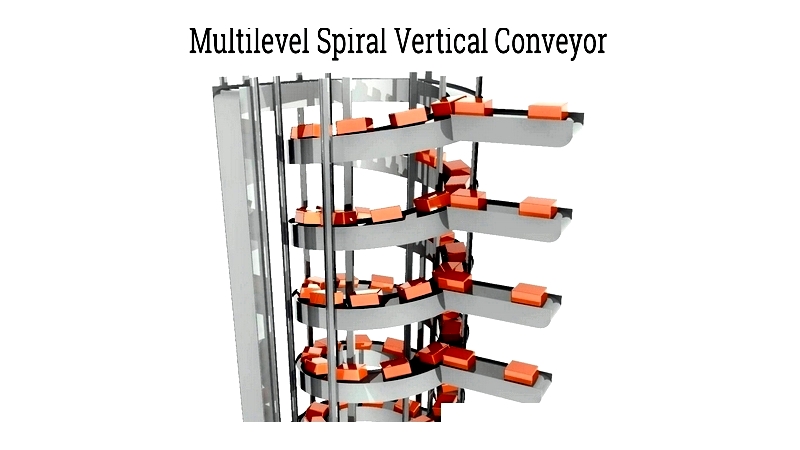

Spiral Vertical Conveyors

Spiral vertical conveyors are continuous motion systems designed for efficient material transfer between elevations. Also called spiral elevators or helix conveyors, they fall into two main categories: bulk material conveyors and unit handling conveyors using belts or slats.

Bulk vertical conveyors handle loose materials like grains, sand, or powdered chemicals, typically using a screw mechanism inside a housing tube. They are ideal for vertical and inclined transfer in food processing or chemical manufacturing.

For unit loads, spiral conveyors use modular belts or slats to carry packaged items between levels. Their compact design saves space in environments like packaging lines and distribution centers.

Unlike inclined belts that require more space, spiral conveyors wrap around a central column, enabling compact vertical elevation with controlled incline. This minimizes product spillage or damage during transfer, crucial for high-volume logistics.

Multi-level spiral conveyors feature multiple entry or discharge points at different elevations, benefiting warehouse systems and order-picking operations. In manufacturing, they streamline component delivery to production lines, supporting lean strategies and increasing throughput.

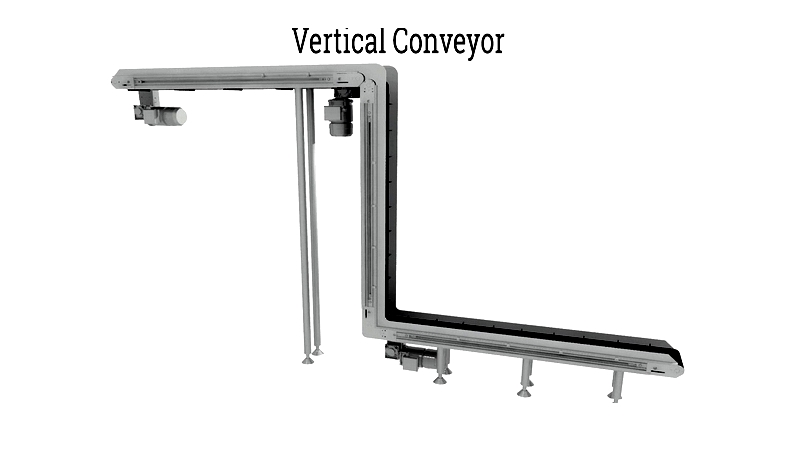

Vertical Reciprocating Conveyor (VRC)

VRCs are industrial lifts designed exclusively for transporting goods—not personnel—between elevations. As material hoists, they are essential for warehouses, manufacturing plants, and mezzanine access. Unlike elevators, VRCs follow material handling safety standards (ANSI/ASME B20.1), resulting in different regulations and fewer inspections.

VRCs are categorized by drive mechanism: hydraulic or mechanical. Hydraulic lifts use cylinders for smooth operation at lower cost, suitable for medium-duty applications. Mechanical lifts, powered by electric hoists or chains, handle heavier loads and higher cycles, ideal for automated production and high-volume operations.

VRCs efficiently move pallets, containers, or parts between levels without forklifts, reducing congestion and improving safety. They often integrate with conveyor belts or pick modules in manufacturing and warehousing. Most feature safety cages, interlocked gates, and load sensors for safe handling. Custom platform sizes and load ratings adapt to various industrial applications.

When installing a VRC, consider site layout, workflow optimization, and long-term material handling strategy. They are common in construction, automotive plants, and multi-story distribution centers.

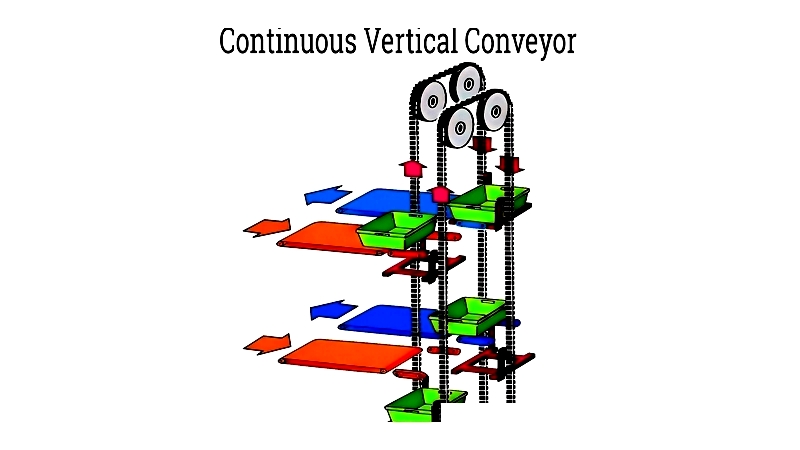

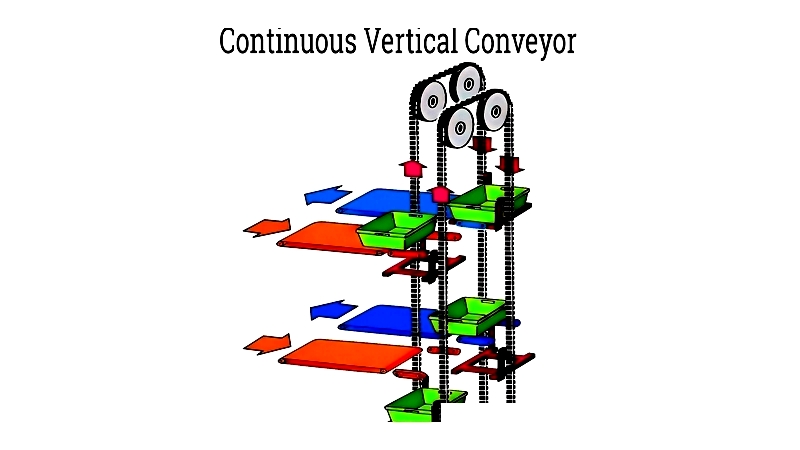

Continuous Vertical Conveyors (CVC)

CVCs, also called box lifters or vertical sortation systems, provide automated transfer of containers, boxes, or packages between levels in high-throughput operations. They handle stable-base items in sectors like e-commerce, parcel sorting, and pharmaceuticals.

- S or Z Type: Cross-floor transfer with entry and exit on opposite sides.

- C Type: Entry and exit on the same side for return loops.

- E Type: Inlet at first floor with multiple upper-level outlets.

- F Type: Multiple inlets and outlets for order consolidation.

- L Type: Right-angle direction change for footprint optimization.

CVCs handle up to 2 tons and reach 120 feet, utilizing vertical space efficiently. Available in materials like stainless steel or aluminum, they can include safety sensors or see-through guarding. Their modular design integrates easily with warehouse automation.

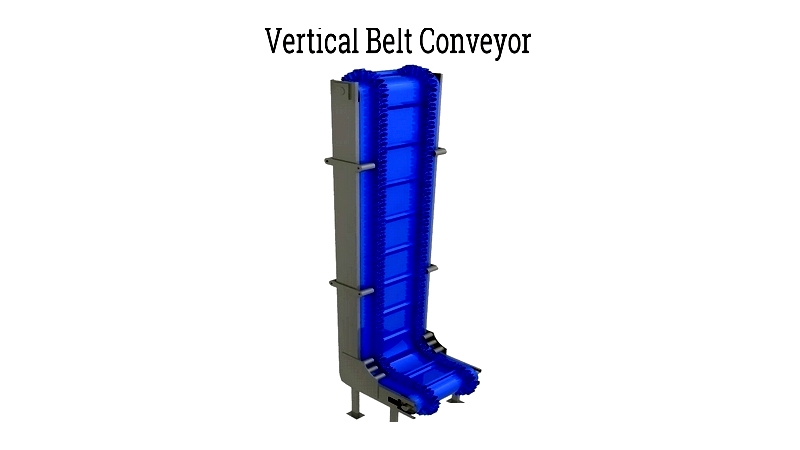

Vertical Belt Conveyor

Vertical belt conveyors, or elevator conveyors, move bulk materials like grains or minerals along steep inclines. They feature cleated or pocketed belts for secure transport in agriculture, mining, or pet food manufacturing.

Design considerations include material characteristics, belt tracking, and pulley interaction to minimize slippage. Options like variable speed controls and dust-tight construction enhance safety and throughput.

Circulating Vertical Conveyors

These conveyors meet multi-level loading needs in automated warehouses. They come in two types: for identical loads (uniform cartons) and variable loads (mixed packages). Their advantage lies in streamlining internal logistics for high-volume vertical transport.

Identical-load conveyors use synchronized platforms, while variable-load systems adjust for different package sizes. Both types promote automated flow and reduce manual handling in dense storage environments.

Bucket Vertical Conveyors

Bucket elevators lift bulk solids like grains or aggregates using attached buckets. They are essential in agriculture, mining, and cement plants.

Three main types include:

- Positive Discharge: For clean unloading of sticky materials like sugar.

- Continuous: Gentle handling of fragile items like plastics.

- Centrifugal: High-speed operation for free-flowing materials like sand.