Introduction

This article provides an in-depth exploration of on-demand manufacturing.

Key topics covered include:

- Understanding On-Demand Manufacturing & Take Rate

- The Relationship Between On-Demand and Take Rate

- Offshoring in On-Demand Manufacturing

- Benefits of On-Demand Manufacturing

- Challenges of On-Demand Manufacturing

- And more...

Chapter 1: Understanding On-Demand Manufacturing

Take-Rate, order commissions, and on-demand manufacturing are fundamentally interconnected. This production approach creates goods, products, and components as required, in specific quantities and within defined timeframes. By eliminating excessive inventory and warehousing expenses, it helps businesses market their products more effectively. The model operates on immediate production initiation upon order receipt, ensuring timely deliveries and rapid turnaround.

The Take Rate Equation

Xometry maintains an effective take rate of approximately 20%.

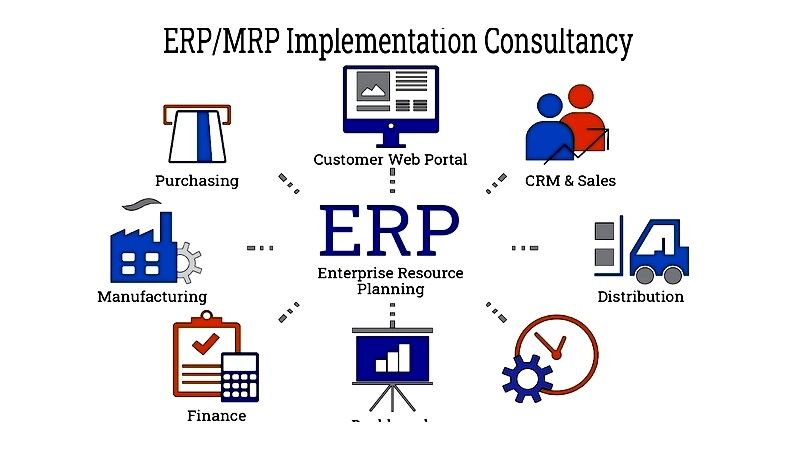

Unlike many B2B marketplaces, Xometry operates a more managed system. After providing AI-generated quotes to buyers, it connects them with suitable suppliers through its marketplace. The fragmented nature of manufacturing makes it ideal for marketplace solutions, enabling Xometry to sustain its 20% take rate.

The platform simplifies access to global suppliers in an otherwise disconnected market. For manufacturers, it offers free lead generation, eliminating marketing burdens. While suppliers pay nothing, buyers cover the take rate difference between Xometry's charge and the manufacturer's payment.

Source: Bowery Capital

This model aligns supplier capabilities with buyer needs, optimizing resource use. As an alternative to offshore production, it enhances market responsiveness. Recent technological advances have boosted its adoption, though many "local" providers actually rely on international networks, introducing potential risks.

Short-Run Production Dynamics

On-demand manufacturing often involves short-run production, necessary when scaling is limited or capabilities are insufficient. Traditional manufacturing depends on long-term partnerships and extended production cycles, making short-run solutions challenging due to cost factors. On-demand manufacturing overcomes these hurdles through advanced technology and specialized expertise.

Advanced software matches buyer specifications with supplier options, optimizing resource allocation. After price agreement, the platform mediates the transaction, typically charging 5-20% of the order value.

Conventional Manufacturing: Long-Run Production

Conventional manufacturing remains the backbone of modern economies, characterized by mass production using specialized equipment. Evolving from early assembly lines, it now incorporates robotics, automation, and AI to enhance efficiency.

Its primary benefits include cost-effective mass production and consistent quality output. Automated processes ensure adherence to strict standards, particularly in industries requiring precision. Continuous technological integration keeps conventional manufacturing competitive in meeting contemporary demands.

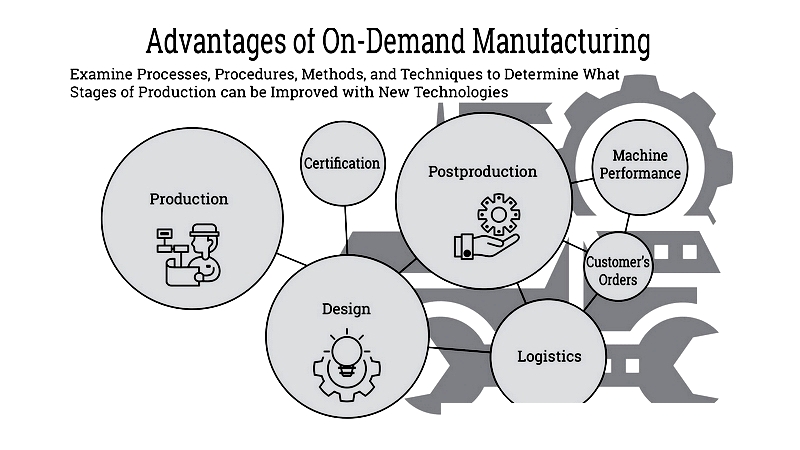

Chapter 2: Benefits of On-Demand Manufacturing

This flexible production model creates goods only when ordered, utilizing technologies like 3D printing and CNC machining. By eliminating excess inventory, companies align production with actual demand, optimizing supply chains. The system is particularly effective for businesses requiring rapid prototyping or producing customized, low-to-mid volume items.

While ideal for industries like fashion, automotive, and electronics, it's less suitable for mass-producing complex industrial equipment requiring extensive planning.

Key Advantages

- Inventory Reduction: Eliminates need for stockpiling materials and finished goods, minimizing overproduction risks.

- Sustainability Benefits: Particularly valuable in fashion and electronics, significantly reducing material waste.

- Supply Chain Simplification: Allows businesses to focus on core competencies like product design and marketing.

- Customization Capabilities: Enables cost-effective production of highly personalized items in small quantities.

- Lower Capital Requirements: Democratizes manufacturing for smaller enterprises through flexible equipment.

- Innovation Acceleration: Facilitates rapid prototyping and faster time-to-market for new products.

- Transparent Pricing: Many platforms offer instant quoting tools for greater customer convenience.

Additional Benefits

- Ideal for limited-edition products and market testing

- Enhanced supplier-customer collaboration

- Quick resolution of production issues

- Shared success through project-based partnerships

- Greater process control and quality assurance

- Flexibility for design modifications

- Domestic prototyping before offshore scaling

- Competitive advantage in fast-moving markets

In summary, on-demand manufacturing offers scalable, sustainable solutions aligned with Industry 4.0 trends, providing agility and customer-centric production models.

Chapter 3: Challenges of On-Demand Manufacturing

While offering faster delivery and better inventory control, on-demand manufacturing isn't without complexities. Operational, logistical, and quality challenges mean only a minority of implementations run smoothly. Careful partner selection is crucial to avoid delays, quality issues, and cost overruns, particularly with overseas production.

- Middleman Involvement

- Additional Fee Structures

- Liability Limitations

- Intellectual Property Risks

- Material and Technique Constraints

- Scalability Limitations

- Foreign Supplier Dependence

- Environmental Considerations

Middleman Considerations

Most platforms act as intermediaries between buyers and manufacturers, typically charging 5% or more for their services. While some simply connect parties, others manage full logistics and quality control. Understanding these differences is crucial when selecting a provider.

Fee Structures

The middleman model adds 10-20% to costs, making it less economical for high-volume production. Without economies of scale, per-unit costs remain higher than traditional manufacturing. These fees can significantly impact profitability, especially for startups and small businesses.

Liability Concerns

Standard contracts often limit intermediary liability for defects or delays. Buyers should carefully review terms regarding intellectual property, data ownership, and dispute resolution before committing.

Production Control Challenges

Reduced direct oversight can lead to communication gaps and specification errors, particularly with overseas production. This becomes problematic for precision components or time-sensitive projects.

Quality Assurance Issues

Distributed supplier networks create consistency challenges, especially for regulated industries. Robust quality management systems are essential to prevent nonconformities.

Intellectual Property Risks

Sharing designs with multiple parties increases IP theft potential. Protective measures like NDAs and encrypted transfers are recommended, especially for technology products.

Material and Process Limitations

Options for advanced materials and specialized techniques are often restricted. Certification requirements may further limit available solutions.

Scalability Constraints

While excellent for prototyping, on-demand methods struggle with mass production economics. Traditional techniques often prove more cost-effective at scale.

Global Supply Chain Risks

Dependence on international suppliers introduces geopolitical, currency, and logistics uncertainties that can disrupt production timelines.