Introduction

This article provides an in-depth discussion about hydraulic cylinders.

It covers detailed information on various topics, including:

- What is a Hydraulic Cylinder?

- Types and Piston Configurations of Hydraulic Cylinders

- Design of Hydraulic Cylinders

- Considerations for Choosing a Hydraulic Cylinder

- And Much More...

Chapter 1: What is a Hydraulic Cylinder?

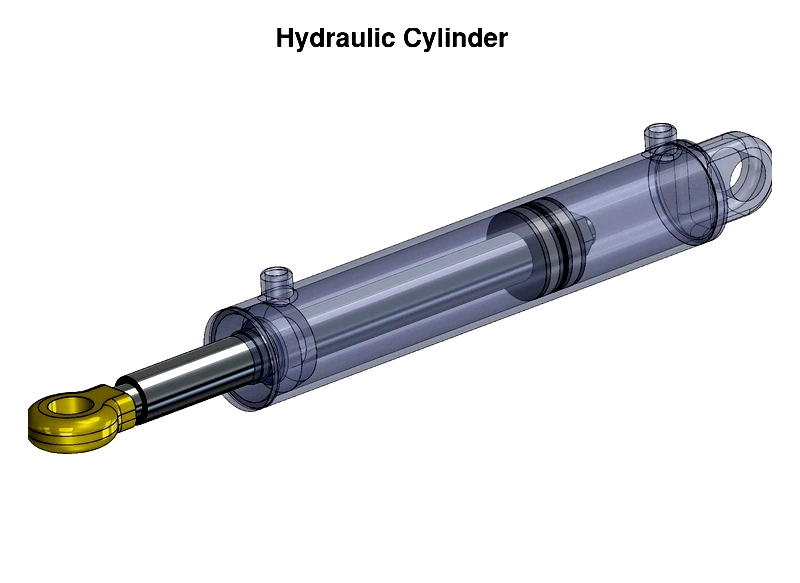

A hydraulic cylinder is a mechanical device designed to generate linear motion through hydraulic pressure. It works by using hydraulic fluid pressure to move a piston forward (pushing) or backward (pulling).

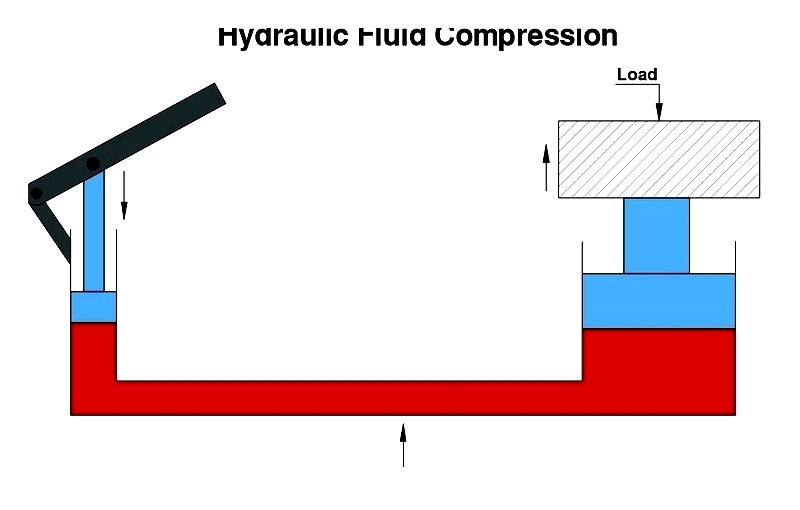

This operation is based on fundamental principles of physics, including:

- Hydraulic fluids cannot be compressed.

- Pascal's Law: In a static fluid within a sealed container, any pressure change is transmitted equally throughout the fluid and container walls.

-

begin{equation} Pressure = frac{Force}{Area} end{equation}

To create a system using these principles, refer to the setup illustrated below.

Since hydraulic fluids are incompressible, pistons A1 and A2 remain stationary until an external force is applied. Applying force to one piston causes the second piston to move, as calculated using Pascal's Law.

The pressure on the left piston with Area A1 and Force F1 is defined by:

Because pressure is transmitted equally through the fluid, the pressure on the right side matches the left side:

Therefore, we determine:

Thus, the force on the opposite side is the applied force multiplied by the area ratio. With the force known, displacement can be easily calculated.

Hydraulic cylinders are crucial for powering movements in industrial and commercial manufacturing. They are used in various fields, such as:

- Aerospace: Operating landing gear and wing flaps

- Automotive: Earth-moving equipment

- Agriculture: Hydraulic systems in tractors

- Civil Engineering: Excavators, bulldozers, and attachments

- Petroleum industry

- Power Generation: Water gate flow control systems

- Highway repair and maintenance

- Mining: Excavator applications

Chapter 2: Types and Piston Configurations of Hydraulic Cylinders

This chapter examines the different types and piston configurations of hydraulic cylinders, which are essential components in modern fluid power and motion control systems used in heavy equipment, manufacturing, construction, and automation industries.

In various applications and industries, hydraulic cylinders may also be called hydraulic actuators, hydraulic rams, or hydraulic pistons. Understanding these terms is important when sourcing suppliers or evaluating hydraulic systems, as terminology can vary by context and sector.

Hydraulic Actuators

While pneumatic actuators are often used for fast, precise, and lower-force motion, hydraulic actuators are designed for applications requiring high force output and the ability to move heavy loads with precision. In industrial automation, process control, and heavy machinery, hydraulic actuators provide the power needed for equipment like presses, excavators, loaders, and industrial valves. Hydraulic actuators are typically based on the piston-cylinder mechanism and are found in both linear and rotary motion systems.

Hydraulic cylinders come in various sizes and pressure ratings, making them suitable for customized solutions in construction equipment, agricultural machinery, manufacturing presses, and marine vessels. Selecting the right cylinder size, type, and bore is critical in hydraulic system design to ensure efficiency, longevity, and safety.

Small Hydraulic Cylinders

Small hydraulic cylinders, also known as compact or micro cylinders, feature a stable design, ease of operation, and durability, making them ideal for long-term use in space-constrained applications. They are commonly used in robotics, medical devices, material handling, woodworking, and automation equipment with intricate components. Despite their small size, compact cylinders can deliver significant force, depending on bore size and working pressure.

Key factors when selecting a small hydraulic cylinder include material type, maximum pressure rating, mounting style (such as flange or clevis mount), stroke length, and compatibility with hydraulic fluids or lubricants.

Hydraulic cylinders can be made from various materials, such as:

Stainless Steel Hydraulic Cylinders

Stainless steel hydraulic cylinders are ideal for applications requiring corrosion resistance, such as chemical processing, food production, pharmaceuticals, and marine environments. While most hydraulic cylinders are made from alloy steels like 1045 and 1018 for their strength, these materials can rust in wet or humid conditions. Protective coatings like epoxy paint can be used on carbon steel cylinders, but coatings may degrade over time, exposing the metal to corrosion.

Stainless steel hydraulic cylinders resist pitting and corrosion even in harsh conditions, making them suitable for offshore oil rigs, deck machinery, shipboard cranes, davits, and boat lifts. Their robust construction reduces maintenance costs and extends service life, making them valuable for industries needing reliable hydraulic actuation in corrosive environments.

Types of Hydraulic Cylinders

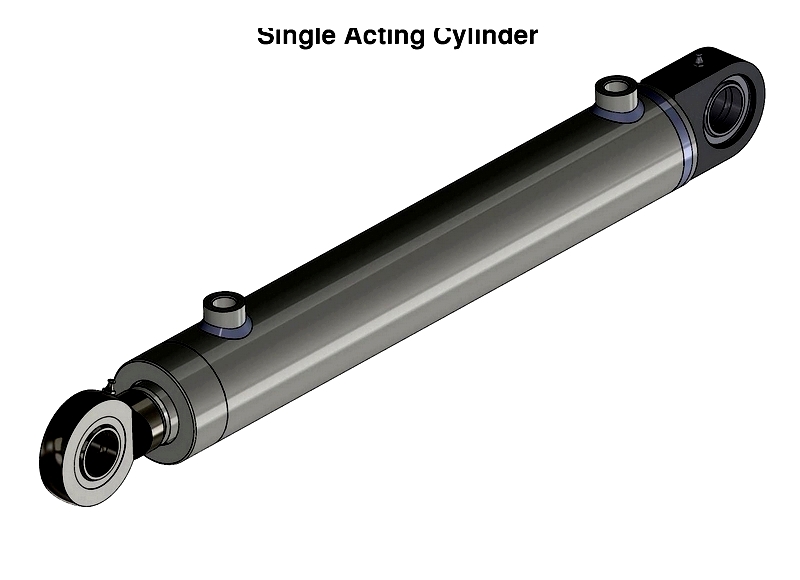

Hydraulic cylinders are categorized as single-acting or double-acting based on how hydraulic fluid moves within the cylinder. A single-acting hydraulic cylinder has one port and chamber pressurized, producing movement in one direction. A double-acting cylinder has two chambers and ports, allowing hydraulic fluid to move the piston both forward and backward for bidirectional operation. Understanding these types is essential when specifying hydraulic cylinders for power transmission, heavy lifting, or automated machinery.

Single Acting Hydraulic Cylinder

A single-acting hydraulic cylinder uses hydraulic power in one direction, either extending or retracting the piston, depending on the design. The pressurized chamber's location depends on the intended motion: for pushing, hydraulic fluid enters the chamber opposite the rod, while the other chamber contains a return spring. For pulling, hydraulic fluid is applied to the rod-side chamber, with the opposite chamber's spring providing the return mechanism.

Advantages of Single Acting Cylinders

- Simpler design, manufacturing, and installation due to single-port configuration

- Lower initial and maintenance costs

- Compact housing for space-limited applications

- Reduced valve and piping requirements lower system costs

Single Acting Disadvantages

- Reduced thrust due to opposing spring force

- Performance decline and inconsistent stroke as spring wears over time

- Limited to unidirectional force applications

Double Acting Hydraulic Cylinder

Double-acting hydraulic cylinders have two ports for hydraulic fluid, enabling precise movement in both extension and retraction. This configuration allows for high precision, speed, and force in applications like industrial presses, injection molding machines, and construction equipment. Since both