Introduction

This article provides an in-depth examination of dust collectors.

You will explore topics including:

- The history of dust collectors

- What is a dust collector?

- Dust collecting systems

- Types of dust collection systems

- Used dust collectors

Understanding Dust Collectors

Dust collectors are advanced air purification systems designed to improve air quality in industrial and commercial environments by removing particulate contaminants. These systems efficiently capture pollutants and solid particles that are regulated by government agencies due to air pollution concerns. Particles released during manufacturing processes can pose health risks, including respiratory problems. Dust collection systems purify polluted air using filters or separators that collect these particles.

The Occupational Safety and Health Administration (OSHA), established in 1971, regulates indoor air quality in workplaces, while the Environmental Protection Agency (EPA), founded in 1970, sets emission limits for industrial pollutants like dust and smoke. Facilities must comply with these regulations to avoid penalties, including potential shutdowns.

Manufacturers depend on dust collection systems to meet strict requirements. System selection depends on the specific pollutants and manufacturing processes involved. only OSHA and EPA-approved systems are permitted. Companies must choose systems tailored to their operations and regularly evaluate them to maintain compliance with air quality standards.

Air pollution is measured using the air quality index (AQI). Higher AQI values indicate poorer air quality. Each country determines acceptable air quality levels, with daily pollution measurements converted to a numerical scale starting at zero. An AQI below 50 represents good air quality, while values between 300 and 500 indicate hazardous conditions.

The Evolution of Dust Collectors

During the Industrial Revolution in 1852, as industries produced large amounts of dust and byproducts, American inventor S.T. Jones patented the first dust collector—a single bag filter. This design was improved in 1921 by German inventor Wilhelm Beth, who patented a three-filter system focused on air and gas filtration.

The 1950s introduced pulse jet filtration systems, which transformed the industry by reducing mechanical components. By the late 20th century, stricter air quality regulations in the 1970s and 1980s made dust collectors essential. Today, the industry continues to innovate, developing smaller, cleaner, and more efficient filtration systems.

Dust Collecting Systems

Dust collecting systems are vital for controlling air pollution in industrial settings, reducing dust and airborne contaminants in workshops, manufacturing plants, and woodworking facilities. These systems are crucial in industries like metalworking, pharmaceuticals, and food processing, where production generates hazardous dust particles. Without proper dust collection, air quality, machinery performance, and worker health can suffer. To comply with OSHA and EPA regulations and protect workers, facilities use advanced dust collection equipment.

While dust collecting systems can occupy significant space and are difficult to reconfigure, their benefits are substantial. Well-designed systems extend equipment life by preventing dust buildup, reduce fire risks from combustible dust, and protect workers from harmful particulates.

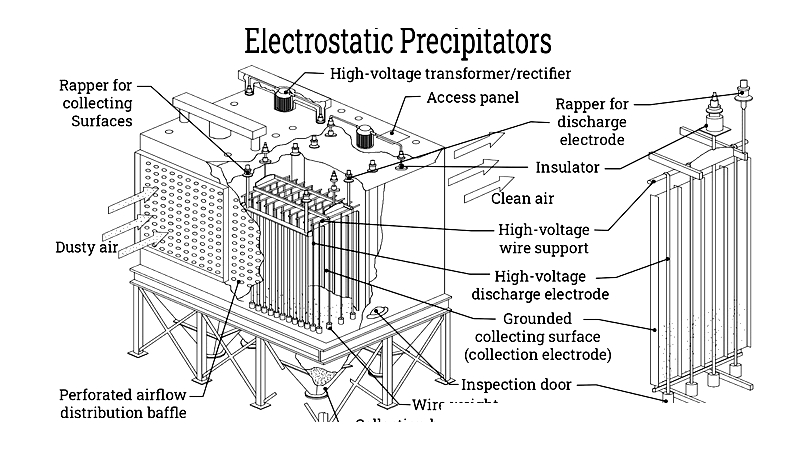

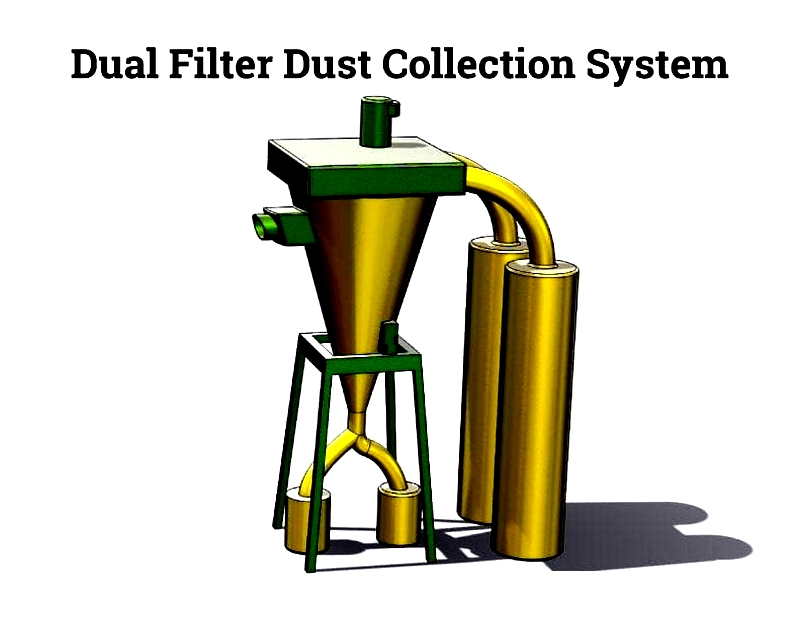

A dust collecting system includes key components for effective dust capture and airflow management, such as ductwork, collection hoods, and a central vacuum unit. The blower assembly, with its powerful engine and high-efficiency fan, maintains optimal airflow. The filtration unit features a dust housing, clean air plenum, and filter elements like cartridge filters or bags. Advanced systems may include sensors, HEPA filters, and automatic cleaning mechanisms.

Dust collection technology began with simple baghouse systems, where air passed through filter bags. Modern systems are classified as positive- or negative-pressure designs, based on fan placement. Negative-pressure systems, which draw air into a vacuum, are preferred for their efficiency and safety features.

Dust collector configurations vary to meet specific needs. Portable units are ideal for small shops or temporary workstations, using compact fans and HEPA filters. Larger operations use central systems with branched ductwork for multiple work zones.

Selecting the right system involves evaluating dust type, air velocity, filter compatibility, maintenance needs, and compliance standards. Manufacturers offer customized solutions, replacement filters, and maintenance services to ensure long-term safety, cleanliness, and regulatory compliance.