Introduction

This article provides an in-depth exploration of vibratory conveyors.

You'll gain insights into key topics including:

- What vibratory conveyors are

- How vibratory conveyors operate

- Selection criteria for vibratory conveyors

- Key features of vibratory conveyors

- Different types of vibratory conveyors

- Pros and cons of vibratory conveyors

- Common applications of vibratory conveyors

- Maintenance best practices for vibratory conveyors

- And much more...

Chapter 1: Understanding Vibratory Conveyors — Functionality, Selection Criteria, and Key Features

Vibratory conveyors are specialized material handling systems designed to transport everything from fine powders to coarse grains. These robust machines efficiently move bulk materials of varying sizes, with horizontal movement being their primary operation. While their suspension design imposes some limitations, vibratory conveyors offer significant speed advantages over traditional belt conveyors, particularly in silo applications where belts often fail due to material pressure or rapid wear. Their design effectively prevents clogs and maintains operation even after disruptions, performing best in horizontal or slightly inclined configurations.

A vibratory conveyor typically features an accumulation track (linear or gravity-based) to stabilize materials while minimizing vibrations. Drive systems may use pneumatic, electromagnetic, or piezoelectric motors to generate the necessary torque, force, and vibration for material transport.

The transport trough forms the core of the system, moving materials through precise linear vibrations that facilitate bouncing and progression. Speeds range from a few feet to over 100 feet (30 meters) per minute, adjustable by modifying vibration frequency, amplitude, and incline angle.

Similar to fluid control valves, different vibratory conveyors manage material flow. These systems use frames with soft springs to cushion vibrations, enabling steady bulk material delivery at rates from a few pounds to multiple tons per hour. They prevent bridging - a common flow obstruction - through their flow-through design that minimizes friction-related blockages. Material flow can be controlled through direct force application to the deck or via indirect force using resonant frequencies.

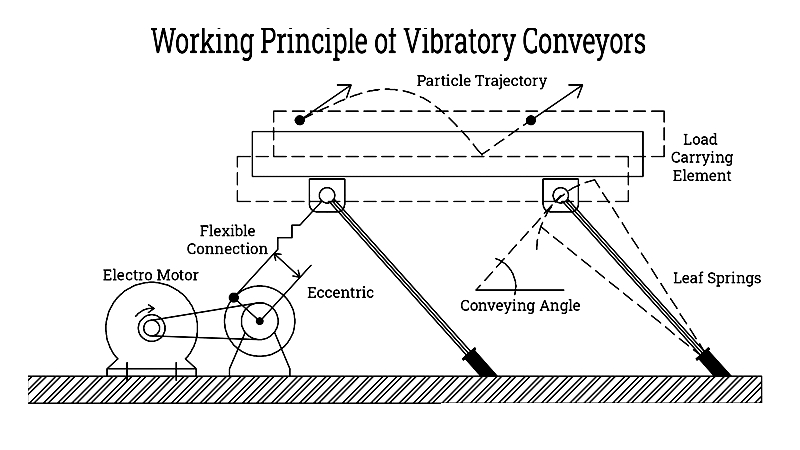

Working Principle of Vibratory Conveyors

As their name suggests, vibratory conveyors use vibration to transport materials along production lines. Electromagnets generate these vibrations by converting electromagnetic energy into mechanical motion. The conveyor, mounted over a permanent magnetic coil powered by an external source, moves vertically with spring support. Typically, 1 to 6 electromagnets work together beneath the feeder base, creating mechanical vibrations that move components onto bowl conveying tracks for further processing.

Considerations When Choosing Vibratory Conveyors

- evaluate required transport distance, optimal width, and necessary vibration characteristics. For instance, long-distance rock transport needs wider troughs and larger drives. These factors help determine the appropriate conveyor and its power requirements.

- Define what materials need transporting, required quantities, and desired speed to establish load capacity and throughput. This information helps suppliers recommend suitable conveyor size, shape, and duty rating.

- Consider control needs and special requirements like damping foundations, sterile environment containment, or hazard prevention. Suppliers can help identify appropriate solutions for specific applications.

Characteristics of a Vibratory Conveyor

- Easy discharge capacity regulation (e.g., using inverters for precise tonnage control)

- Effective transport of diverse materials (powders, granules, large blocks)

- Low maintenance costs and minimal wear

- Customizable features for special conditions (dust covers, liner plates, sealing components)

- Smooth operation with consistent vibrations

- Adjustable grid design prevents blockages

- Optional frequency converter motors for easy feed rate adjustment

Electromagnetic Vibratory Conveyor by PPM Technologies

Electromagnetic Vibratory Conveyor by PPM Technologies

Chapter 2: Types of Vibratory Conveyors

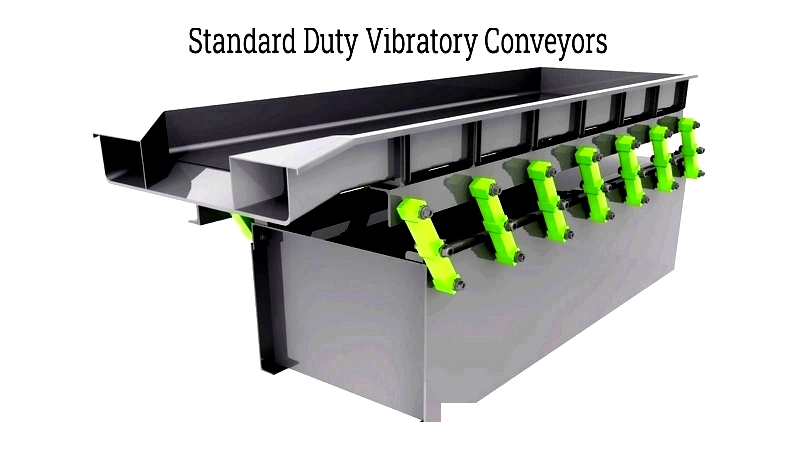

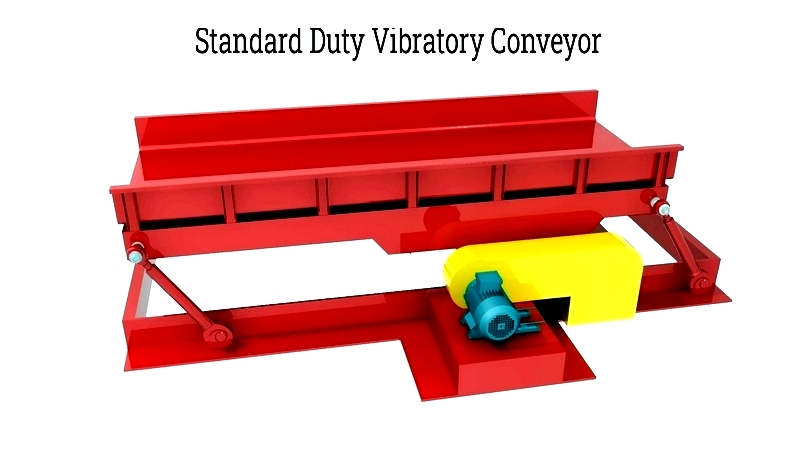

Standard-Duty Vibratory Conveyors

Designed for medium-to-light density materials like plastics, wood, and porous rock, these conveyors serve industries including polymer manufacturing, chemical processing, aggregates, and food production. With capacities of 1-40 tons/hour and speeds up to 60 feet/minute, their robust construction ensures durability with minimal maintenance. They effectively transport granules, chips, pellets, and powders in both automated and standalone operations, available in closed or open trough designs.

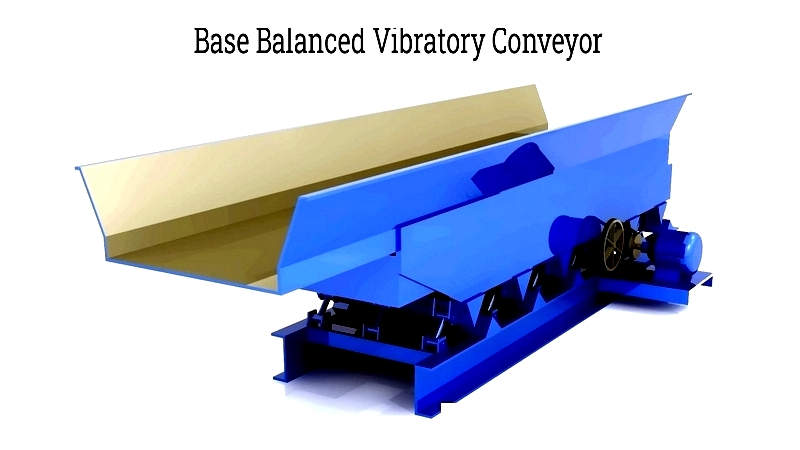

base-Balanced Vibratory Conveyors

Featuring vibration-isolated frames operating near natural resonant frequencies, these conveyors can be installed on lighter structures than unbalanced models. Their heavier frames absorb dynamic forces, reducing noise and structural impact. Throughput speed is adjusted via spring configuration, while eccentric drives control motion amplitude. Limited to about 40 feet in length, they excel in fluidizing, dewatering, classifying, and conveying heat-sensitive materials.

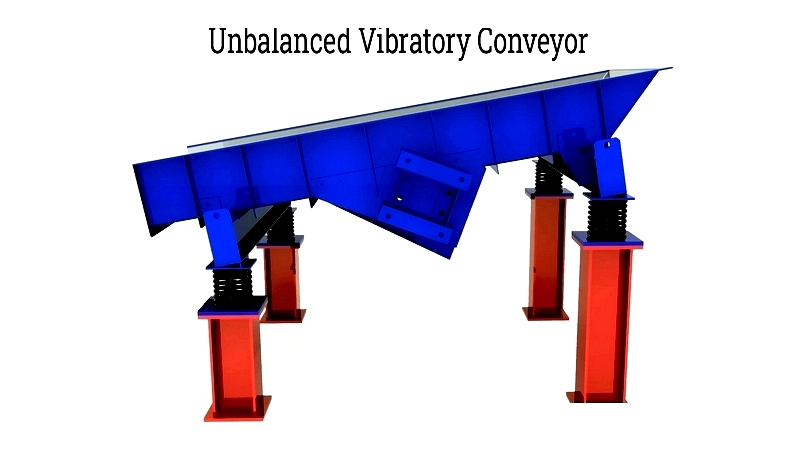

Unbalanced Vibratory Conveyors

Designed for high-capacity continuous flow, these conveyors require sturdy mounting on reinforced concrete or steel frames to handle substantial vibrations. Suitable for lengths exceeding 100 feet, they're ideal for mining, mineral processing, and steelmaking applications. Regular maintenance (bearing lubrication, belt inspection) ensures reliable operation in demanding environments.

Horizontal Vibratory Conveyor by PPM Technologies

Horizontal Vibratory Conveyor by PPM Technologies

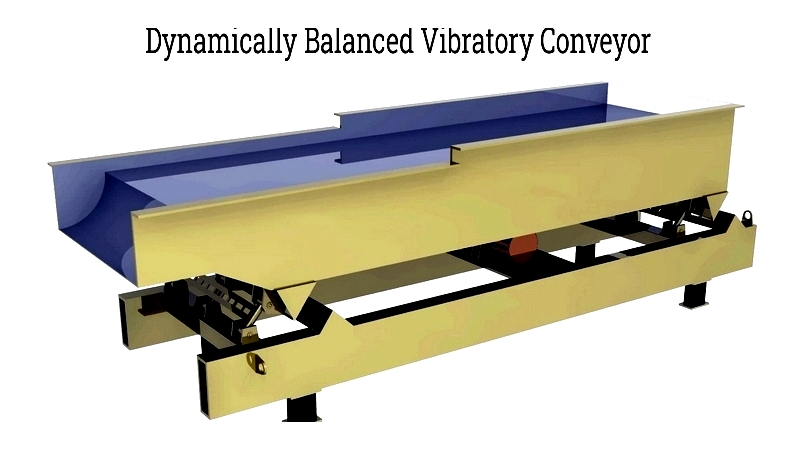

Dynamically-Balanced Vibratory Conveyors

These conveyors feature optimized mass distribution for reduced power consumption and smoother operation, suitable for elevated installations. Their design minimizes vibration transmission, making them ideal for precise process control and delicate material handling. While limited to about 40 feet like base-balanced models, they excel in fluidizing, dewatering, and sorting applications.

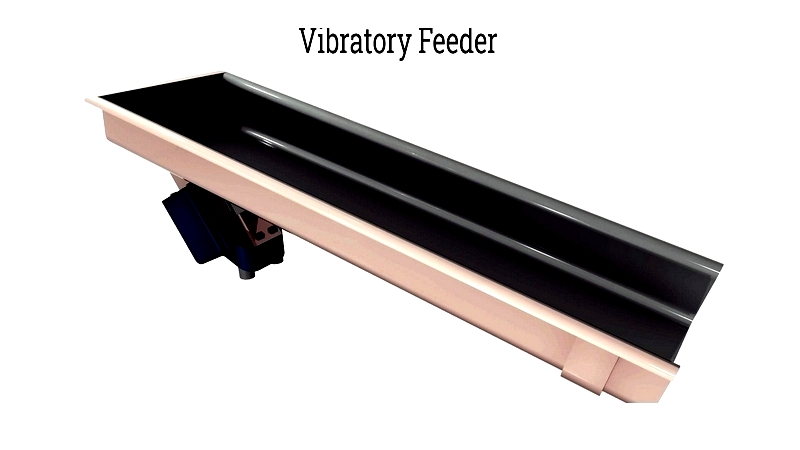

Feeder Vibratory Conveyors

Simple, efficient designs for metering and dosing operations, popular in food processing, packaging, and pharmaceuticals. Typically under 12 feet long with adjustable trough widths, they feature variable-frequency drives for precise flow control. Their sanitary design facilitates clean-in-place operations with minimal maintenance requirements.