Introduction

This comprehensive guide covers differential pressure switches and their applications.

You'll discover:

- The fundamentals of Differential Pressure

- Methods for Measuring Differential Pressure

- Varieties of Differential Pressure Switches

- importance of Differential Pressure Measurement in Switch Applications

- Practical Applications of Differential Pressure Measurements

- And additional valuable insights...

Chapter One: Understanding Differential Pressure

Differential pressure refers to the pressure difference between two distinct points, typically measured using specialized instruments. Gauges and switches are essential components in this process, playing a vital role in monitoring and controlling pressure levels. These devices activate alarms or interrupt circuits when pressure exceeds or falls below predetermined thresholds.

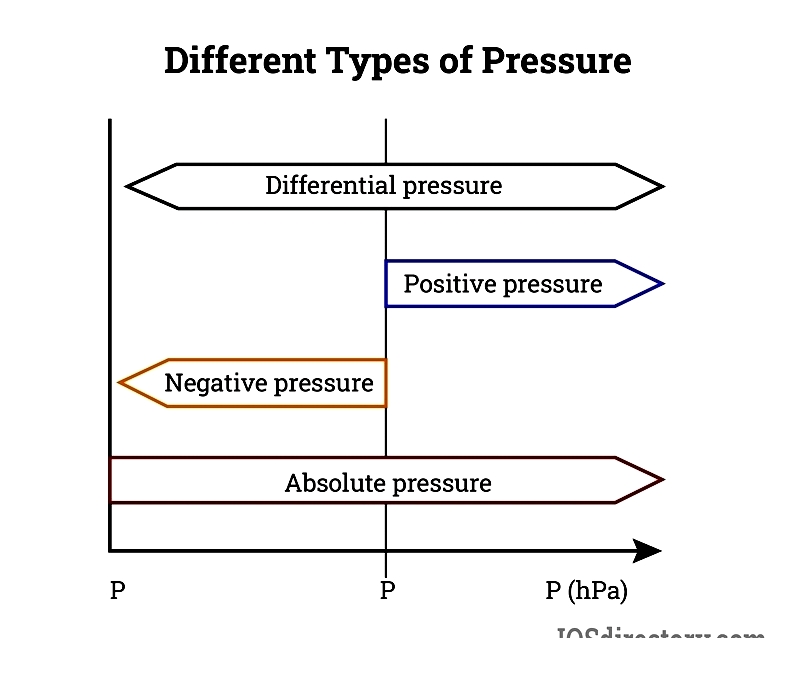

Pressure measurements fall into three main categories: relative, absolute, and differential. Relative pressure measures the difference between a given pressure and atmospheric pressure, while absolute pressure references a perfect vacuum as its zero point.

Measuring differential pressure involves determining the difference between two potentially unknown pressures. Sensors connected to both pressure sources gather data, with gauges or switches calculating the difference. When reaching specific thresholds, these switches control circuit operations. Precise differential pressure monitoring is crucial in industries handling fluids and gases where accurate control is paramount.

Selecting appropriate differential pressure measurement methods depends on factors like application requirements, pressure range, maximum pressure exposure, and medium characteristics. While manual calculations are possible, they're often time-consuming and prone to errors. Modern differential pressure gauges and switches provide more accurate and efficient solutions.

Chapter Two: Measuring Differential Pressure in Liquids

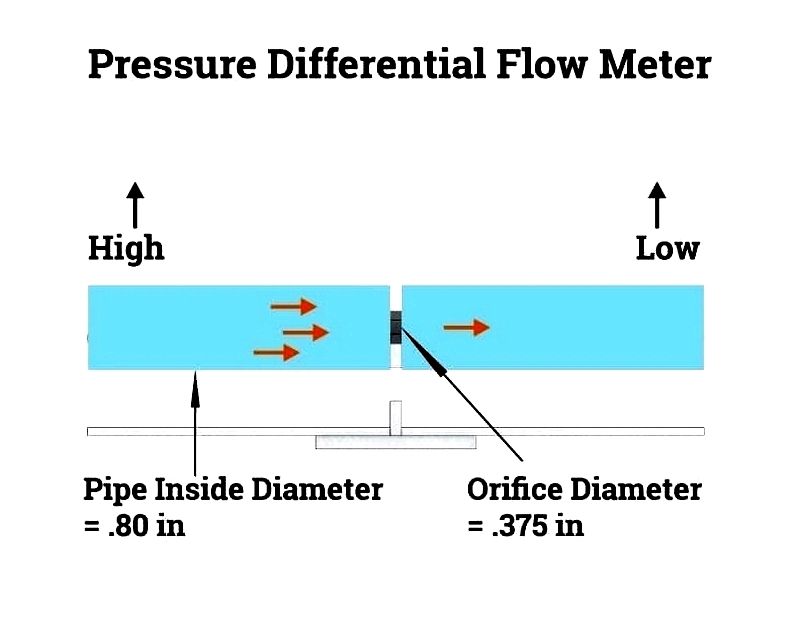

Differential pressure measurement in liquid systems is crucial for industrial automation and fluid control. This process evaluates pressure differences across flow restrictions like orifice plates or filters, with the pressure drop correlating to flow rate. Applications span water treatment, oil & gas, pharmaceuticals, and chemical processing.

Accurate measurements require specialized equipment, proper calibration, and material selection. Considerations include fluid type, temperature/pressure ranges, required accuracy, and compliance with industry standards.

Common measurement devices include manometers, diaphragm seals, and digital pressure transmitters with electronic sensors. Digital models offer remote monitoring and system integration capabilities. Selection depends on required readouts, indication methods, and output signals.

Material compatibility is essential to prevent equipment degradation. Wetted components must resist the measured liquid and withstand system conditions. Corrosion-resistant materials reduce maintenance and extend service life.

Stainless steel offers durability and corrosion resistance, suitable for harsh environments. Brass provides cost-effective solutions for lower-pressure applications. Plastics like PVC and PTFE suit chemical-resistant requirements.

Best practices include proper installation, regular calibration, optimal sensor placement, and quality fittings. Consulting specialists ensures appropriate equipment selection for specific liquid applications.

Chapter Three: Measuring Differential Pressure in Gases

Differential pressure transmitters are widely used in gas measurement applications. These instruments employ sensitive diaphragms to detect pressure differences, converting them to electrical signals for system monitoring.

While liquid measurement techniques apply, gas measurements require additional considerations for temperature, pressure, and density variations. Advanced sensors incorporate compensation features for accurate readings.

Gas leaks pose measurement challenges. Specialized gauges and transmitters incorporate enhanced sealing and leak detection for reliable operation.

Selection criteria include material compatibility, pressure range, accuracy, and output signals. Consider display requirements, communication protocols, and hazardous area certifications.

Accurate gas pressure measurement supports energy management, flow verification, and process safety. Proper equipment selection enhances efficiency and regulatory compliance.

Chapter Four: Differential Pressure Switch Operation

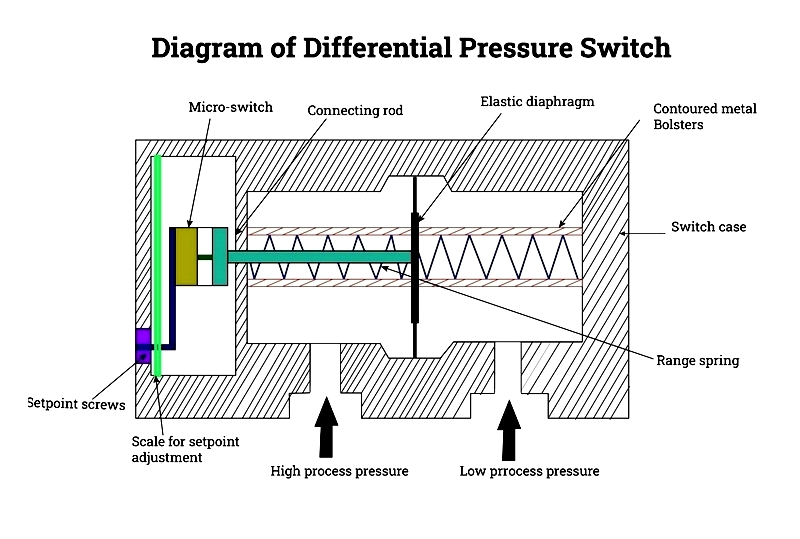

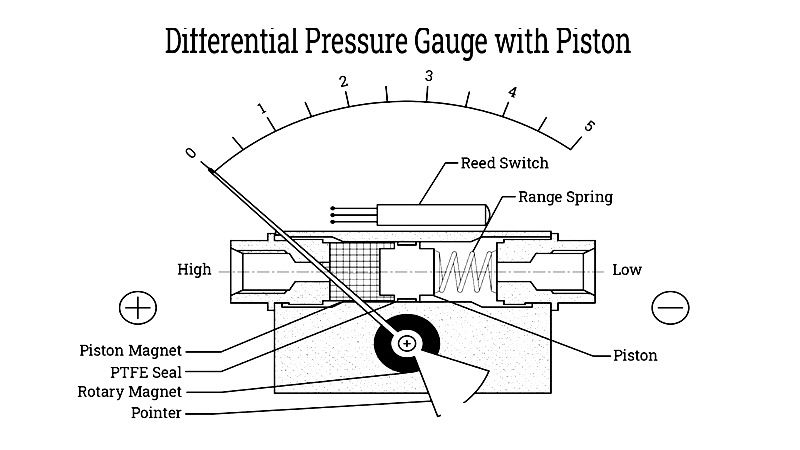

These switches comprise three main components: sensing element, range spring, and microswitch. Various configurations serve different industrial applications.

Operating on lever principles, the device detects pressure differences via a diaphragm. The resulting force activates a microswitch through spring tension.

Dual-port designs separate high and low pressures with a diaphragm. Pressure differential creates axial movement that operates the switch mechanism.

Sensing Elements

Pressure sensing converts medium-induced displacement into measurable responses. Common elements include:

- Diaphragm - Circular plate deflecting under pressure

- Capsule - Dual-diaphragm design for low-pressure measurement

- Bourdon Tube - Oval cross-section tube distorting under pressure

- Bellows - Expanding element indicating pressure levels

Spring

The spring resists sensing element movement, determining the pressure range. Adjusting spring tension sets the switch actuation point.

Microswitch

Converts axial movement into electrical contacts operation at preset points.

Chapter Five: Differential Pressure Measurement Units

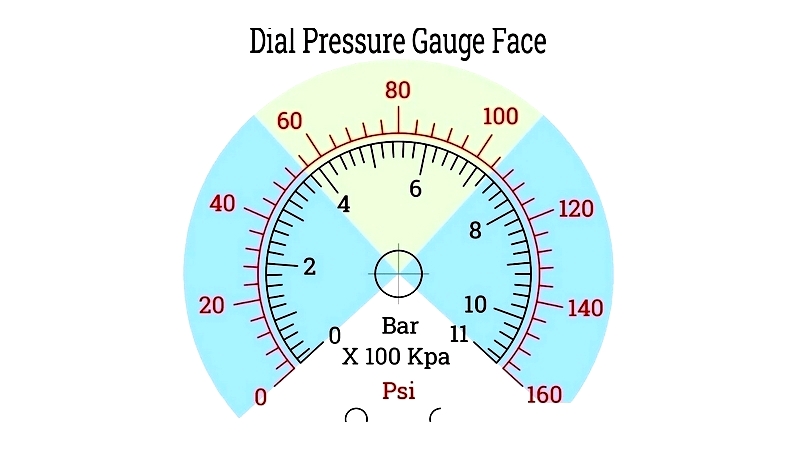

Common units include Pascals (Pa), psi, inWC, and mmHg. Selection depends on application and regional preferences.

The Pascal (SI unit) represents one Newton per square meter. In differential pressure, it indicates the difference between two points.

PSI (US customary) measures one pound-force per square inch difference.

Key differences: Pascals dominate scientific use globally, while psi prevails in US industry. Proper unit selection ensures measurement accuracy, especially in critical applications.

Chapter Six: Differential Pressure Measurement Equipment

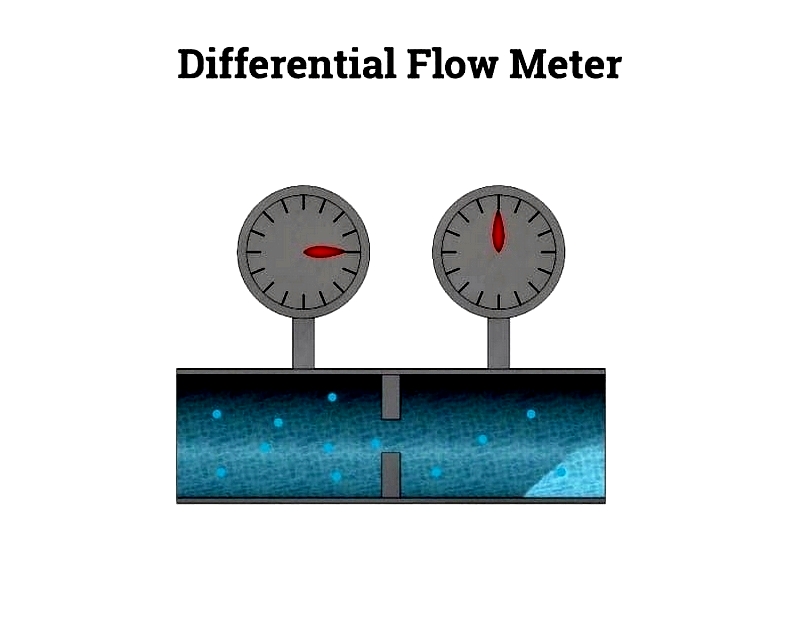

Beyond switches, various instruments measure differential pressure, each suited to specific applications.

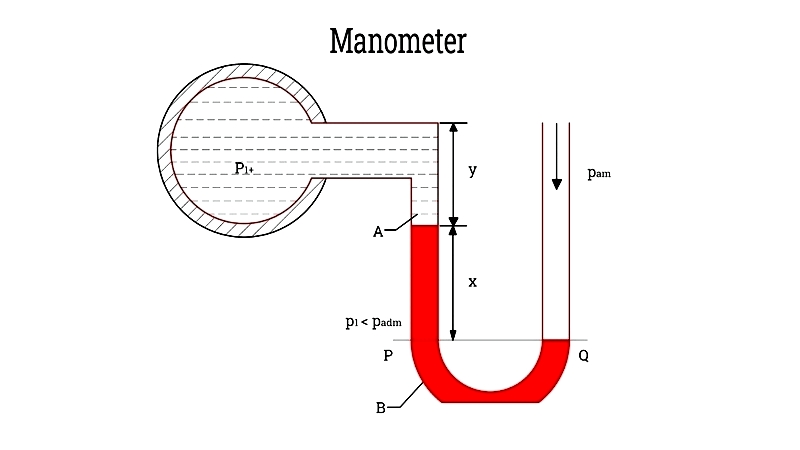

Manometers

Basic pressure measurement devices comparing against fluid columns. Types include U-tube and inclined models for HVAC and industrial use.

Pressure Gauges

Fluid/gas pressure measurement devices including Bourdon tube and diaphragm types for industrial applications.

Differential Pressure Transmitters

Detect pressure variations between system points, often used with flow measurement elements.

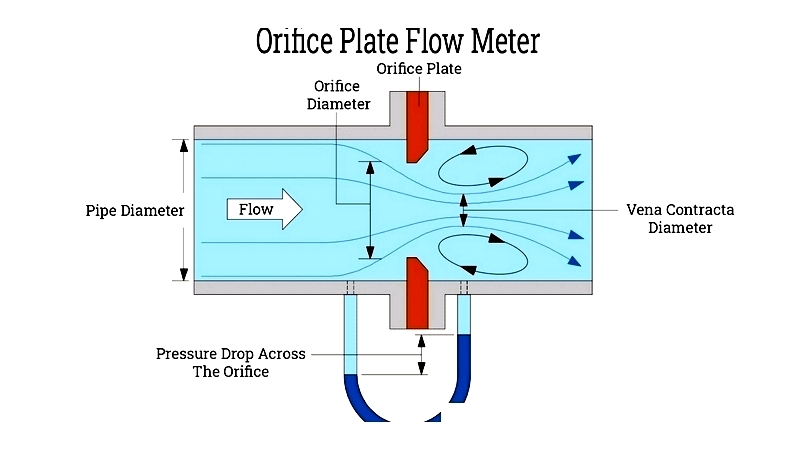

Orifice Plates

Create pressure differentials across central apertures for flow rate calculation in pipelines.

Venturi Tubes

Pipe constrictions generating measurable pressure drops