Introduction

This article provides an in-depth exploration of bucket elevators and conveyors.

Through this feature, you'll gain insights into various aspects including:

- The definition of bucket elevators/conveyors

- Their working mechanisms

- Key selection considerations

- Different belt and bucket types

- Varieties of bucket elevators/conveyors

- Their advantages and limitations

- Practical applications

- Maintenance requirements

- And more...

Chapter 1: Introduction to Bucket Elevators and Conveyors

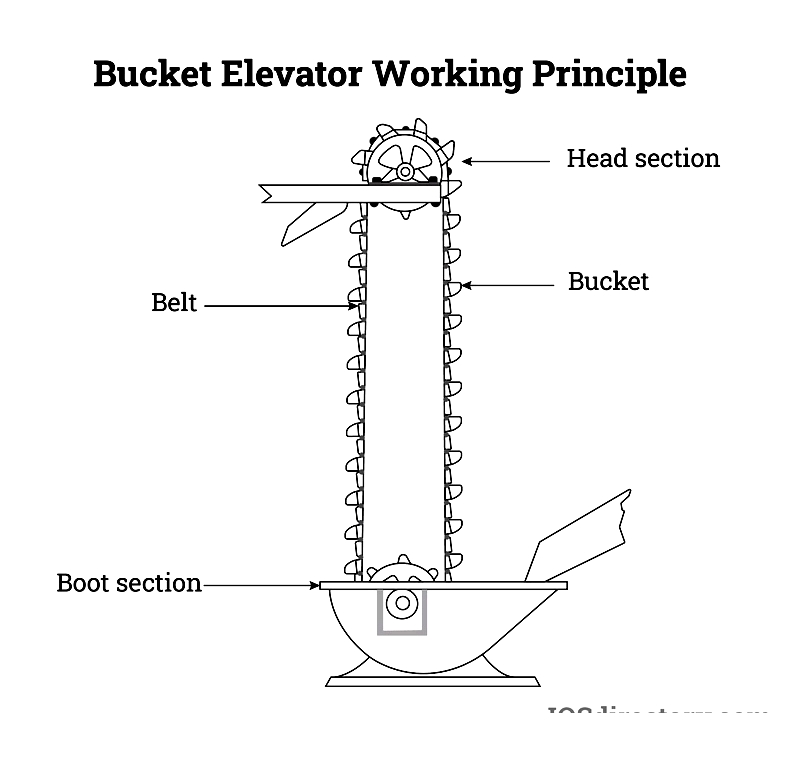

Bucket elevators, also called grain legs, efficiently transport bulk materials. Specialized manufacturers design these systems primarily for commercial agriculture and mining industries.

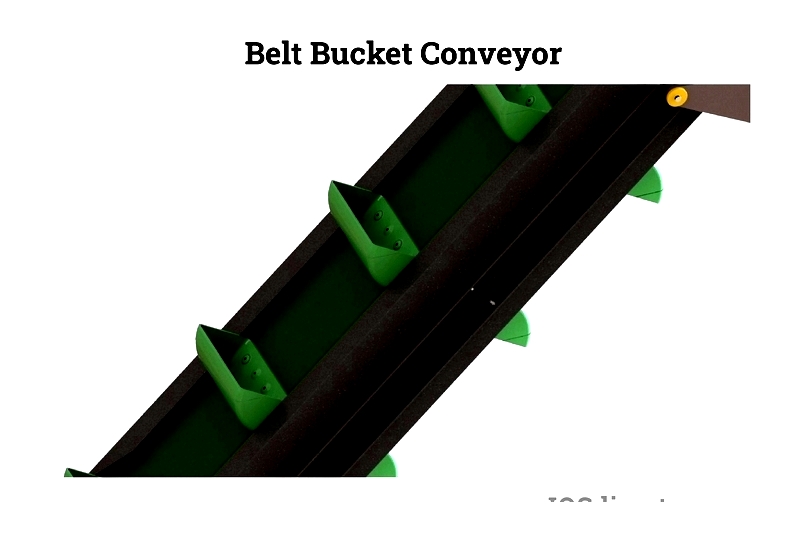

Bucket conveyors feature dual-strand roller chains that move materials horizontally or at inclines. Their robust construction and energy efficiency make them ideal for handling hot, abrasive materials while keeping buckets stable during operation.

These devices, often termed bucket conveyors, transfer materials vertically between facility levels. Though "elevator" and "conveyor" are sometimes used interchangeably, they represent different system configurations.

Commonly known as bucket elevators, these machines lift materials vertically using centrifugal force-driven buckets.

Bucket conveyors move materials along inclines, resembling vertical conveyors but with simpler designs better suited for delicate products.

The scooped-edge buckets maintain upright positions to prevent spillage. Typical applications include transporting ore, fertilizer, or grain. In basic systems, materials rise to the top for discharge before empty buckets return for reloading. Discharged materials flow through chutes to storage or processing areas with minimal human intervention. Advanced systems feature programmable unloading and essential safety measures for operator protection.

How Bucket Conveyors Operate

Bucket conveyors use reciprocating buckets for vertical material transport, typically handling aggregates or bulk goods. The system comprises interconnected troughs that ascend without spilling. Materials enter at the "boot" and discharge mechanically. This automated method offers rapid vertical transport. Construction quality ensures durability tailored to material types and lift heights, making them suitable for dry, light powders but not wet substances.

Designed for continuous operation, frequent starts/stops increase spill risks and reduce efficiency. Operational schedules vary from daily cycles to near-constant use. Emergency stops allow immediate shutdowns, while advanced models include obstruction sensors.

Selecting Bucket Elevators and Conveyors

- evaluate material properties including aeration needs, adhesiveness, and environmental factors before discussing specifications with suppliers. For instance, centrifugal conveyors work well for grains, while gentler systems suit fine materials like sand.

Chapter 2: Bucket and Belt Varieties in Elevators/Conveyors

Bucket Types

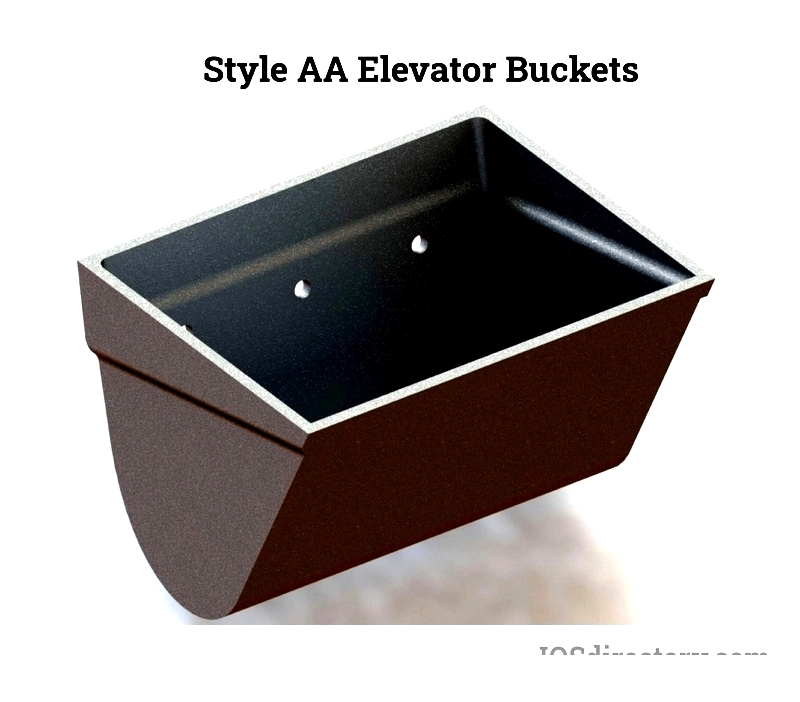

Style AA: These cast iron centrifugal buckets feature reinforced rear walls and durable edges for demanding applications like stone, sand, and cement handling. Their deep design supports high-capacity transport at fast speeds in mining and construction industries.

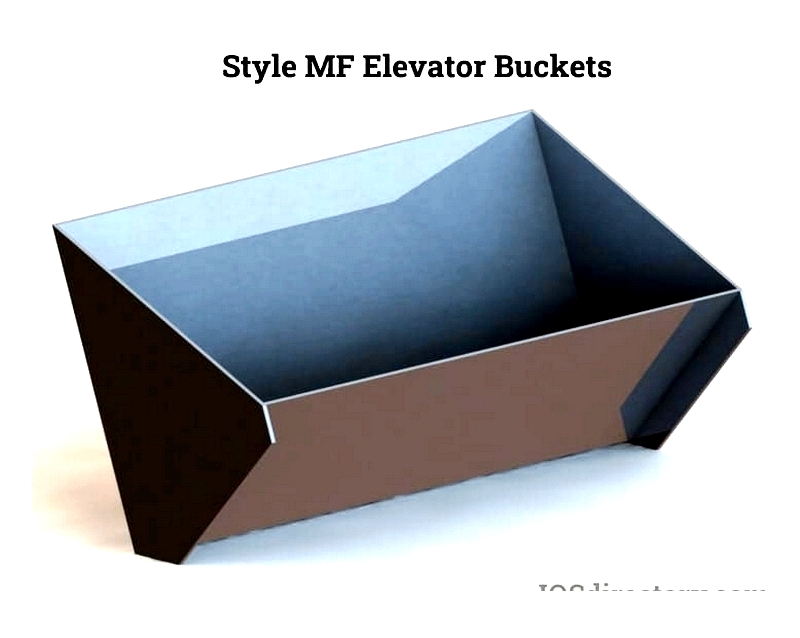

Style MF: With reinforced construction, these steel buckets gently handle pellets, clay, and fertilizers. Their medium front design balances capacity with product protection in agricultural and chemical processing.

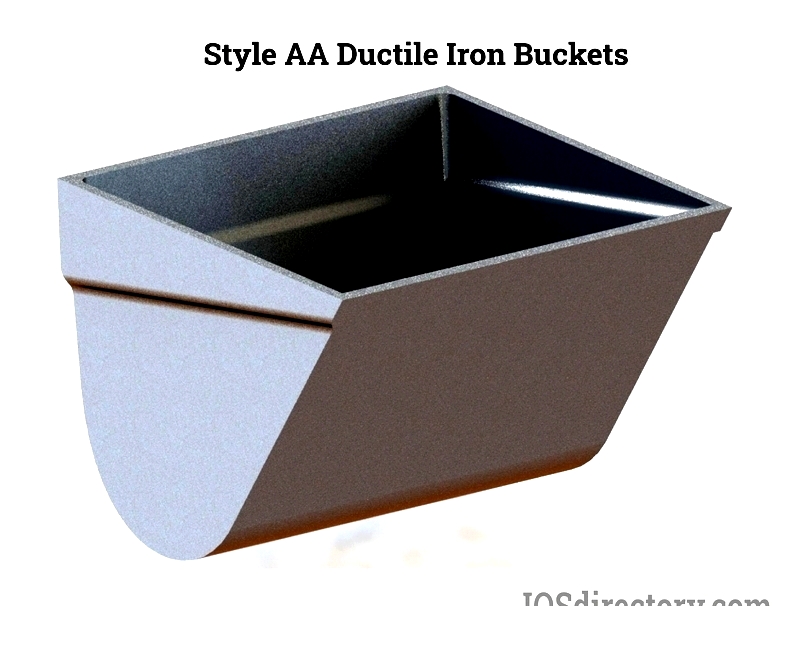

Style AA Ductile Iron: These heavy-duty buckets feature thicker walls and robust lips for abrasive materials. Their superior impact resistance benefits ore processing and heavy industries, reducing maintenance costs.

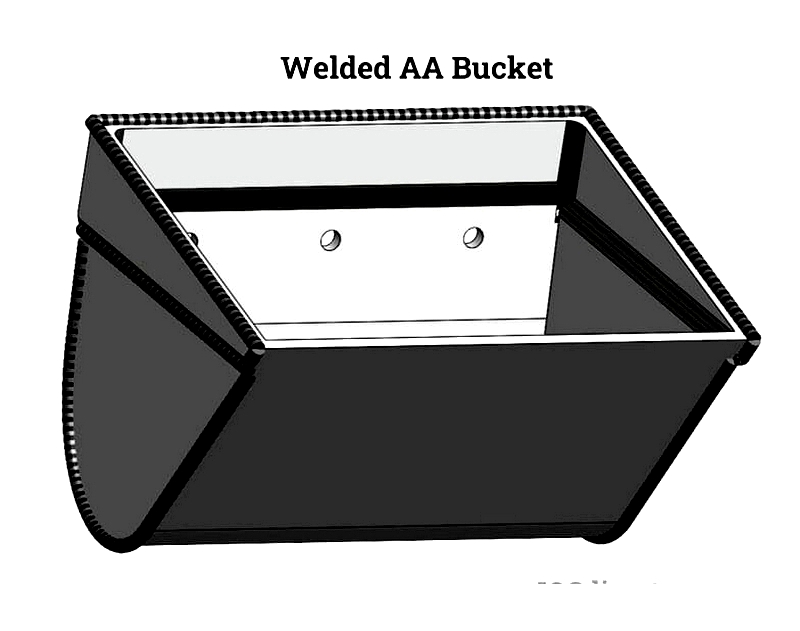

Welded AA Buckets: Comprising three sections with reinforced wear lips, these buckets handle rugged materials in high-throughput systems, ideal for plant upgrades and special applications.

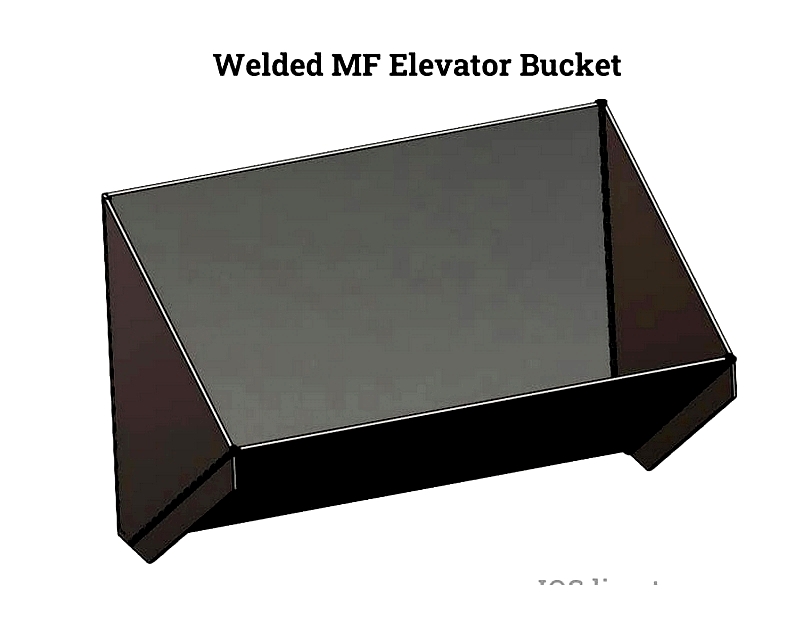

Welded MF Buckets: Featuring front plates welded to press-formed bodies, these buckets gently handle food products and fragile materials while maintaining consistent performance.

Digger Buckets: Engineered for digging operations, these slightly larger buckets withstand additional stress using wear-resistant materials, extending service life in high-abrasion areas.

Specialty Materials: Plastic or polyurethane buckets offer corrosion resistance for food-grade and chemical applications, providing lighter, quieter alternatives to metal options.

Belt Types

Belt selection critically impacts elevator performance. In food and grain industries, belts often require static conductivity, oil resistance, and flame retardancy. Proper traction maintenance through pulley adjustments and lagging ensures smooth operation.

New belts typically stretch 1.5–2% initially, requiring tension adjustments. Repeated stretching indicates aging cords that may lead to failure, necessitating regular inspections.

PVC Belting: Single-ply with cloth cores, these flexible belts suit tight spaces but offer limited chemical resistance. Their lightweight design facilitates clean-in-place operations.

Rubber Belting: Multi-ply fabric-cored belts provide better oil resistance for fatty feeds, grains, and fertilizers. They withstand moisture and heavy loads effectively.

Specialty Belts: Heat-resistant, chemical-resistant, or steel-reinforced belts meet demanding applications in mining, cement, and power generation. Proper selection ensures compliance with safety standards and operational requirements.

Maintenance Best Practices: Regular inspections, tension checks, and preventive maintenance enhance safety, reduce downtime, and extend belt lifespan in all applications.