Introduction

This article provides an in-depth discussion on expanded metal.

It covers various topics including:

- What Expanded metal Is

- Material Types of Expanded metal

- Manufacturing Process of Expanded metal

- Surface Finishing and Shearing of Expanded metal

- Quality Standards for Expanded metal

- Applications and Advantages of Expanded metal

- And More...

Chapter 1: Understanding Expanded metal

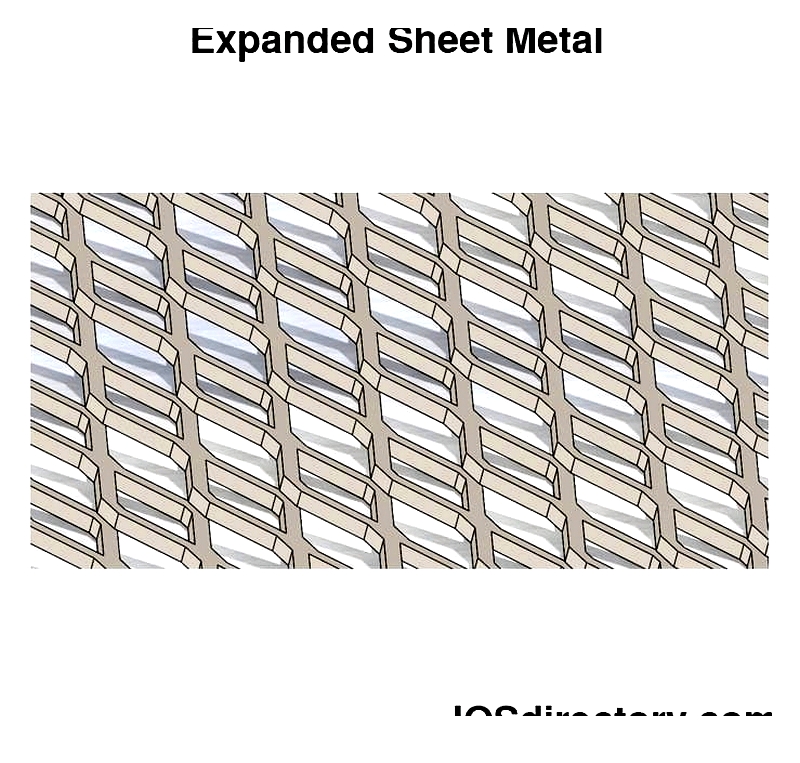

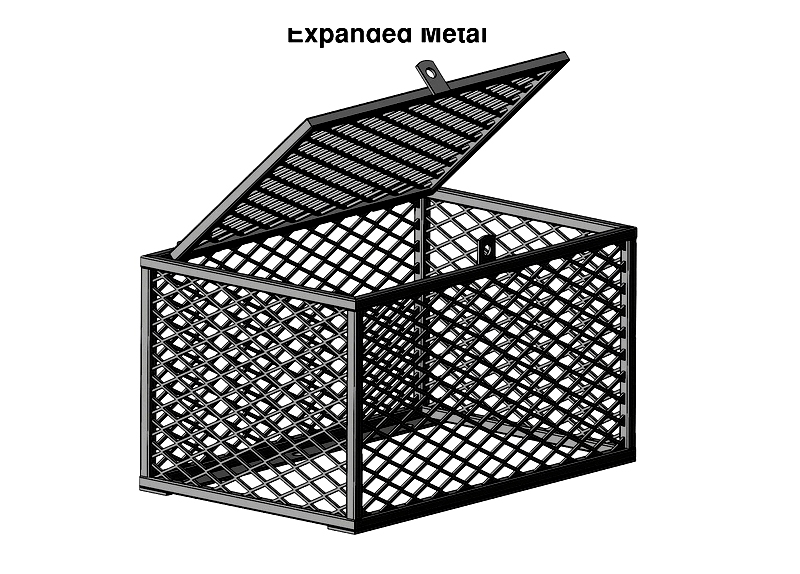

Expanded metal is a specialized sheet metal mesh created by stretching a slitted sheet of ductile metal. The slits are positioned perpendicular to the stretching direction, forming a mesh with multiple holes from the slit sections.

The principle of expanded metal relies on metals' natural tendency to expand and contract under different conditions, determined by their atomic structure and chemical properties.

Expanded metal serves as an alternative to other types, such as:

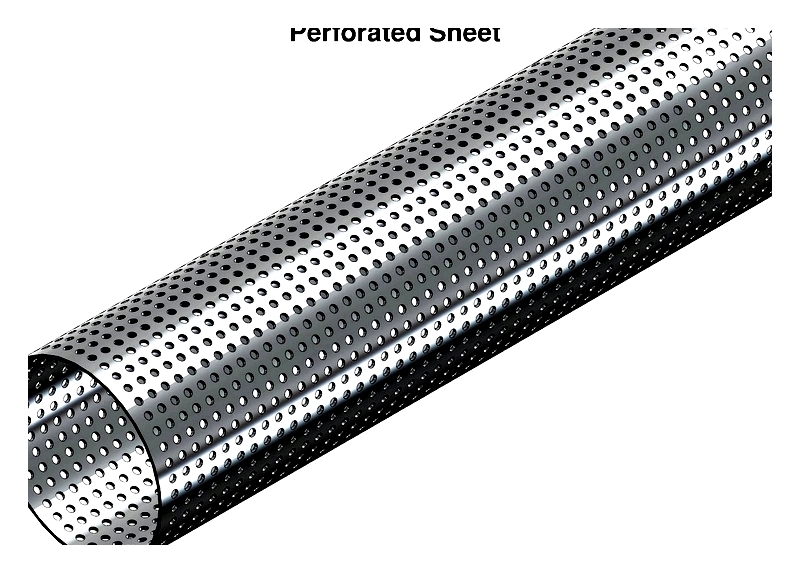

Perforated Sheet

Perforation creates holes in metal sheets, resulting in perforated sheets. While similar materials can be used for both perforation and expansion, perforation is a subtractive process that generates material waste. Unlike expanded metal, perforation doesn't typically involve stretching. Its benefits include creating small openings and drainage systems, as well as enabling unique decorative shapes.

Perforated sheets are commonly used in computer casing designs.

Woven Mesh

This method interlaces metal wires similar to fabric weaving. The weave's integrity depends on friction and wire stiffness since no bonding occurs between wires. Unsecured edges may unravel. Woven mesh is primarily used for sand sieving applications.

Welded Mesh

This mesh features two grids of parallel wires intersecting at 90 degrees, welded at each crossing point. It's ideal for large-area applications, though fine spacing presents production challenges due to the high weld density required.

Welded mesh is frequently employed to reinforce concrete structures.

Chapter 2: Material Types of Expanded metal

Expanded metal can be made from various malleable metals suitable for stretching without fracturing. While many metals can be expanded, only certain types are commonly used commercially due to their performance, availability, and cost. Below are the primary material types used for expanded metal mesh, detailing their properties, advantages, and applications.

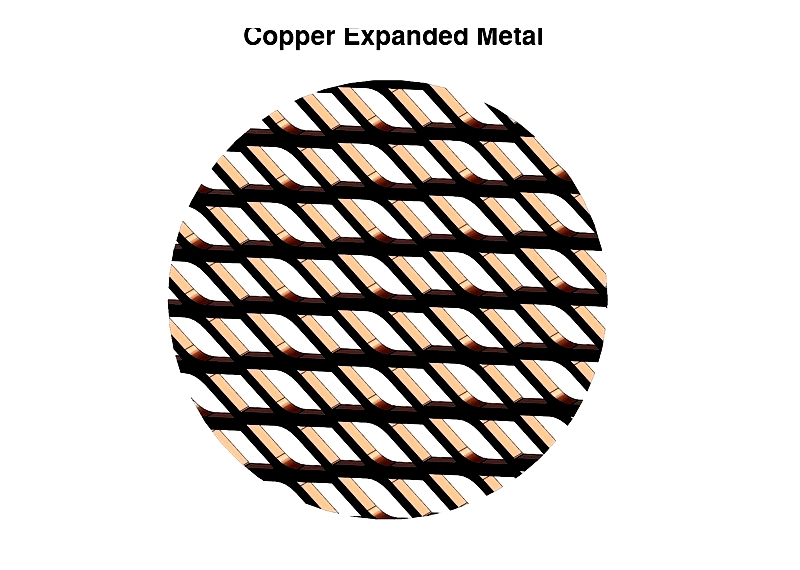

Copper Expanded metal

Copper isn't typically the first choice for structural applications when considering only structural factors, as it's relatively expensive per unit volume. Its high density makes it less suitable for weight-sensitive applications like rigging.

Copper becomes valuable when considering additional factors:

- Corrosion resistance – Ideal for marine, coastal, or chemical processing environments where durability is crucial.

- Electrical conductivity – Superior conductivity makes it suitable for electromagnetic shielding and electrical enclosures.

- Appearance – Its rich color and patina make it popular for decorative and architectural applications.

- Malleability – Easier to work into complex shapes, beneficial for custom mesh fabrication.

Copper expanded metal offers niche solutions combining aesthetic and functional performance.

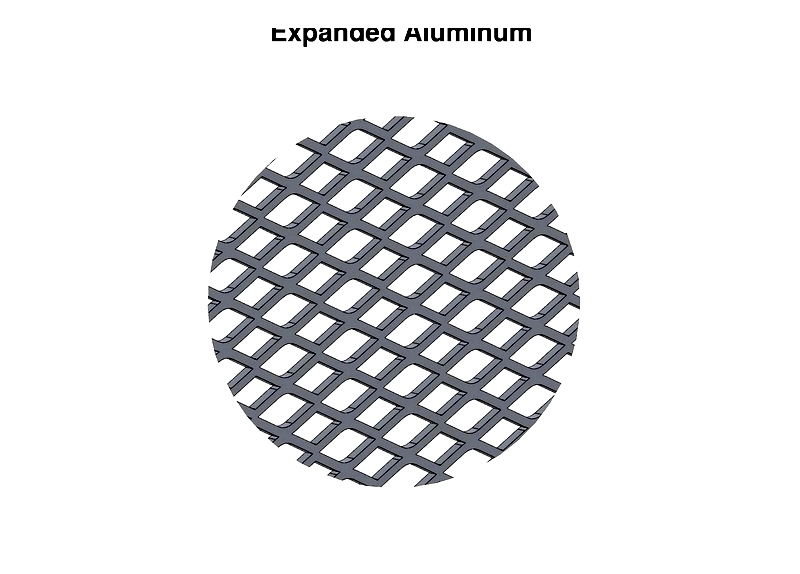

Expanded Aluminum

Aluminum's strength and lightweight properties make it suitable for structural applications. Its conductivity makes it ideal for power lines, while its malleability and corrosion resistance add to its advantages.

Expanded aluminum mesh is valued for:

- Lightweight Strength – Ideal for walkways, partitions, and security panels.

- Corrosion Resistance – Suitable for outdoor and humid environments.

- Versatility – Available in various patterns for architectural and industrial uses.

- Sustainability – Fully recyclable for eco-friendly projects.

Its strength-to-weight ratio and adaptability make it a top choice across industries.

Expanded Steel

Steel is the most widely used structural metal, offering exceptional strength when corrosion-free. Steel expanded metal is versatile for security, fencing, industrial flooring, and architectural uses.

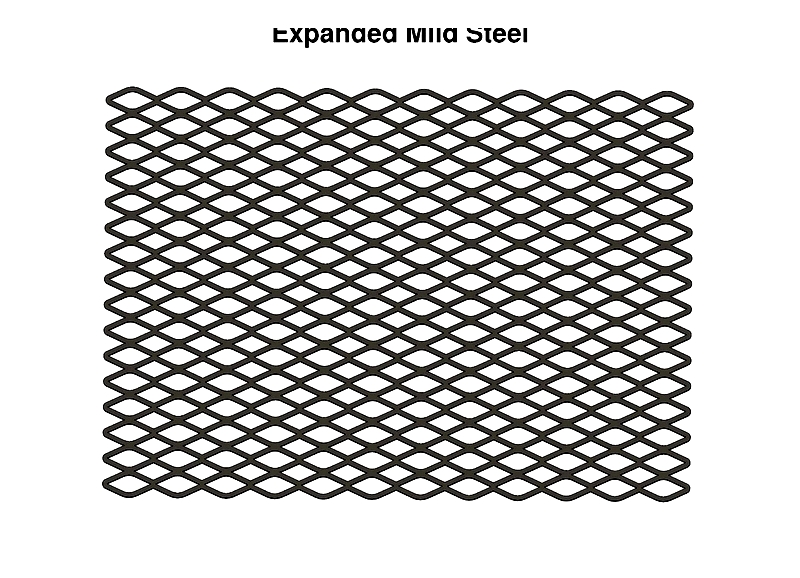

Expanded Mild Steel

An economical solution often galvanized for corrosion resistance, ideal for fencing, grating, and industrial walkways.

Grating metal Sheet

Made from higher gauge steel for heavy-duty applications like industrial flooring and machine platforms.

Stainless Steel Expanded metal

Offers superior corrosion resistance for food processing, pharmaceuticals, and chemical filtration systems.

Key benefits include:

- Durability – High tensile strength for security and industrial uses.

- Low Maintenance – Resistant to staining and corrosion.

- Heat/Chemical Resistance – Suitable for extreme environments.

Material selection depends on application requirements, environmental factors, and budget considerations.