Introduction

This article covers everything you need to know about tape and label cores and their applications.

You will learn:

- What Tape and Label Cores Are

- How Tape and Label Cores Are Manufactured

- The Different Types of Tape and Label Cores

- Common Uses for Tape and Label Cores

- And much more...

Chapter One: Understanding Tape and Label Cores

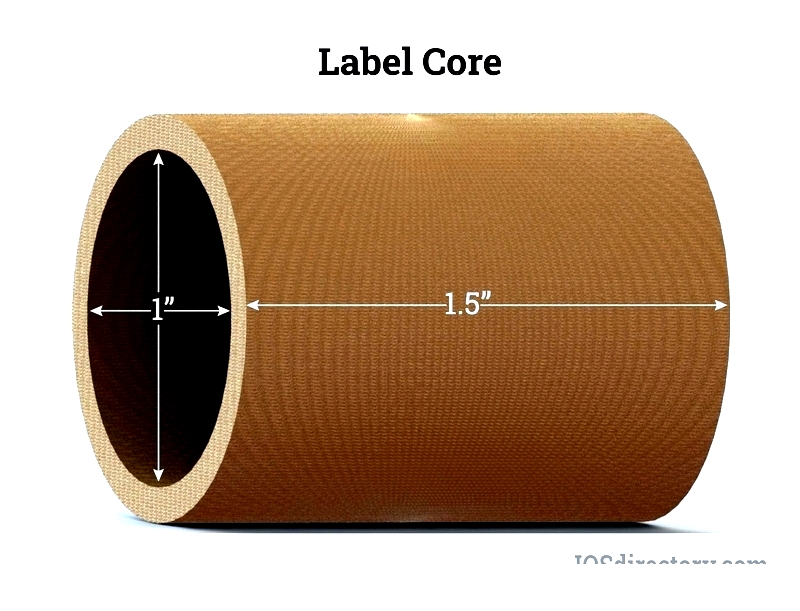

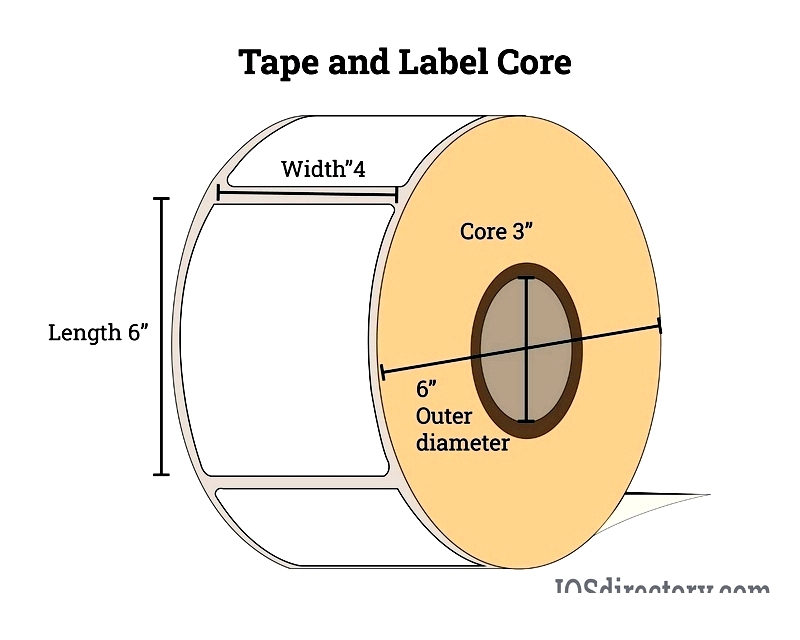

Tape and label cores are sturdy cylindrical bases found at the center of tape or label rolls. While similar in appearance to toilet paper or paper towel cores, they are designed for greater durability and strength. These cores vary in strength, size, material composition, and thickness, with thicker cores typically used for heavier tapes and labels.

When selecting tape and label cores, key considerations include core size (inner diameter, or ID) and the combined outer diameter (OD) of the core plus the tape or label. Additionally, specifying the winding direction is crucial, with eight possible options available.

Rewind directions are determined by label placement—either on the external or internal side of the roll. There are four rewind directions for each placement, creating eight total options. Among these, options 5 and 8 are rarely used, while options 3 and 4 are most common and preferred.

Chapter Two: How Tape and Label Cores Are Made

Tape and label cores are vital components in packaging, printing, and converting industries. Available in various forms and sizes, these cylindrical supports are manufactured using different materials and processes. Understanding their production helps businesses choose the right core for specific applications, enhancing performance, efficiency, and product protection during storage and shipping.

Traditional tape and label cores are made from tightly wound paper, formed on a mandrel and secured with industrial adhesives. Kraft paper is the most common material due to its durability and cost-effectiveness. As needs have evolved, advanced materials and techniques have led to high-performance cores for specialized applications like high-volume packaging, printed labels, and industrial tapes.

Paper cores remain the industry standard for their eco-friendliness, recyclability, and affordability. They are used in masking tapes, pressure-sensitive labels, double-sided tapes, and thermal transfer ribbons. Plastic cores, however, are preferred in sensitive environments like cleanrooms or food and pharmaceutical packaging, where paper dust could cause contamination. Plastic cores also resist moisture, humidity, chemicals, and mechanical impact, making them ideal for harsh conditions. Common plastics include high-impact polystyrene (HIPS), high-density polyethylene (HDPE), polypropylene (PP), polyvinyl chloride (PVC), and acrylonitrile butadiene styrene (ABS).

The manufacturing process for tape and label cores is similar to other cores, with differences in size (typically measured in inches or millimeters), wall thickness, and surface finish. These cores are designed for compatibility with automated unwinding and rewinding machinery, ensuring smooth operation and minimal waste during production.

Core selection depends on the application, ranging from consumer products like retail labels and office tapes to industrial uses such as large-format printing and adhesive tape conversion. Cores must support roll weight, maintain stability, and withstand high-speed winding and unwinding. Material type and wall thickness are critical factors in determining strength, longevity, and resistance to deformation.

It's important to differentiate between mailing tubes and tape/label cores. Tubes are designed for storing and shipping items like posters or blueprints, focusing on protection during transit. Tape and label cores, however, are engineered for rolled materials like pressure-sensitive tapes and printable labels, requiring greater structural strength and dimensional accuracy. Tubes are typically thinner, while cores are thicker and optimized for automated equipment.

Materials

Tape and label cores are made from plastic or paper, depending on the application. Plastic is chosen for heavy-duty materials needing impact resistance and minimal contamination, such as industrial adhesive tapes or medical-grade tapes. Paper cores are ideal for light to medium-duty tapes and labels, offering excellent value and sustainability. For added strength, paper cores can be manufactured with extra plies.

Paper Core Manufacturing

Paper Core Materials

Paper cores are spiral-wound cardboard tubes made from layers of specialty paper, including kraft paper, recycled paper, waterproof cardboard, or dense fiberboard. Recycled content is increasingly popular for sustainability.

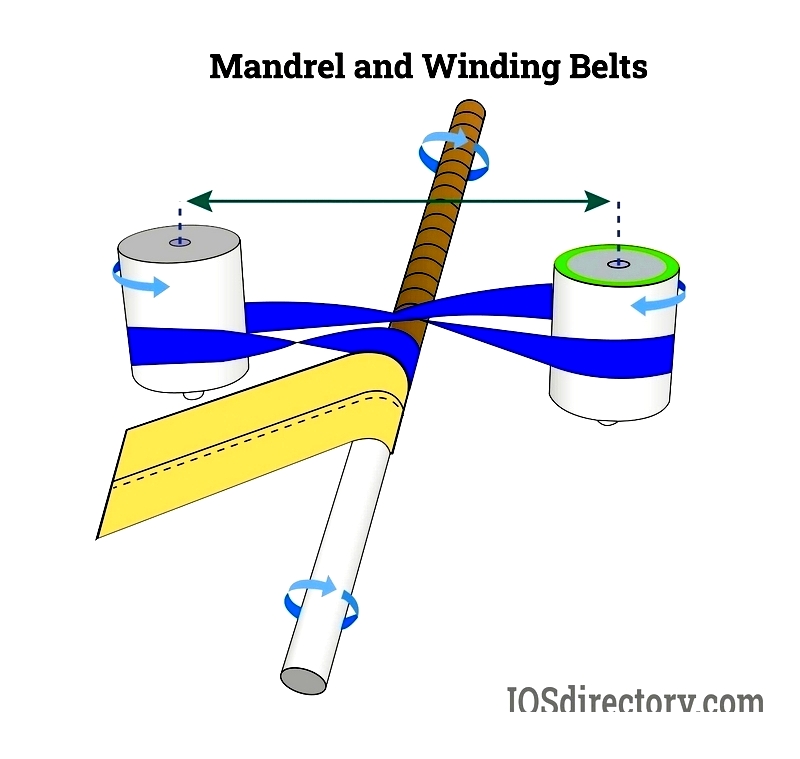

The production process begins with converting large paper rolls into narrow strips, or plies, which are cut to specific widths and thicknesses. These plies are then wound around a mandrel to form the core.

Applying the Layers

During assembly, paper strips are fed through a glue station where adhesives are applied to bond the layers. Adhesive type and application are carefully controlled to ensure core strength and integrity. Factors like bonding strength, core thickness, and ply overlap influence the final product's performance.

Mandrel

The mandrel—a steel rod—determines the core's inner diameter, while wall thickness is set by the number of plies. Modern mandrel technology allows for quick size changes, improving productivity. Tension, speed, and adhesive application are carefully monitored during winding to ensure uniformity.

After winding and curing, the tube is removed from the mandrel and cut to the desired length.

Cutting Process

Precision cutting ensures each core meets specifications. Automated cutters and slitters are standard for high-volume production, enabling rapid changeovers and consistent core widths.

Plastic Core Manufacturing

Plastic Core Materials

Plastic cores are made from engineering-grade polymers like HDPE, PP, ABS, PVC, HIPS, and recycled plastics. Each material offers unique properties for demanding applications.

- Polypropylene (PP): Resistant to cracking, high temperatures, and flexing; ideal for demanding tapes.

- Acrylonitrile Butadiene Styrene (ABS): Impact-resistant and durable; used in challenging environments.

- Polyvinyl Chloride (PVC): Robust against abrasion and heat; suited for heavy-duty applications.

- High-Density Polyethylene (HDPE): Strong, lightweight, and resistant to UV and moisture; ideal for outdoor use.

Plastic cores come in various wall thicknesses and diameters, commonly used in automotive, food packaging, electronics, and medical industries.

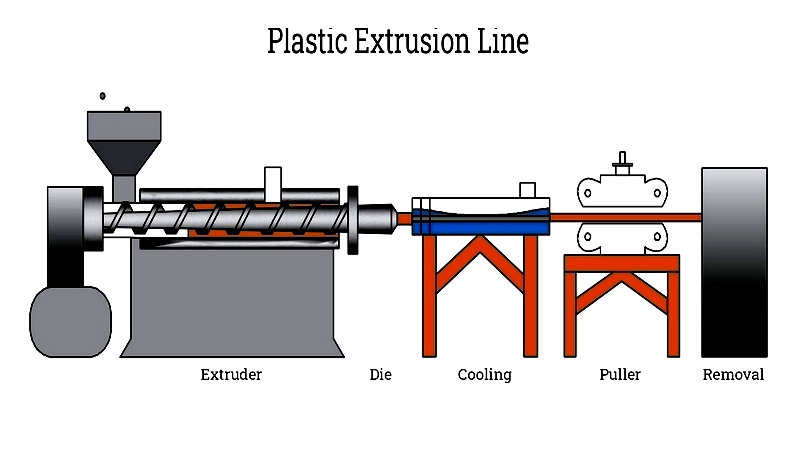

Extrusion

Plastic cores are typically made through extrusion, where melted plastic is forced through a die to form continuous tubes. The die design determines the core's dimensions, with strict process control ensuring consistency.

After extrusion, the tube is cooled and cut to length, allowing for customization based on application needs.

Cutting

Plastic cores are cut using heavy-duty saws or automated systems for precision. Automated equipment with programmable controls ensures consistent results, even with frequent size changes.

Finished cores are shipped to manufacturers for use in high-speed