Introduction

This article provides an in-depth exploration of Cleanroom Products.

You'll discover key topics including:

- What are Cleanroom Products?

- Cleanroom Equipment

- Cleanroom Furniture

- Cleanroom Cleaning Supplies

- And more...

Chapter One – What are Cleanroom Products?

Cleanroom products are specially designed to prevent contamination in highly sensitive environments. Achieving specific classification levels requires cleanrooms to be constructed, cleaned, and maintained according to strict standards. Manufacturers rely on proper cleaners and materials to create ideal conditions for cleanroom production.

Every tool and material used in cleanrooms must meet rigorous specifications. Manufacturers ensure their products comply with ISO standards and US Federal Standards Act 209E requirements.

Chapter Two - Cleanroom Equipment

Cleanroom effectiveness depends on specialized equipment for manufacturing, testing, and research. All devices must meet strict standards to maintain ISO classifications and controlled environments. Proper equipment minimizes airborne particles and supports compliance with ISO 14644 and GMP protocols for pharmaceutical, semiconductor, and biotechnology applications.

Maintaining sterile environments requires rigorous sanitization of all items entering the space. From PPE to HEPA filtration systems, these tools are designed for particle control and easy decontamination. Their key feature is maintaining cleanliness standards and preventing cross-contamination.

Cleanroom Equipment

Fume Hoods

Fume hoods are containment systems that remove toxic fumes and contaminants from cleanroom environments. Various types include PVC ducted hoods, carbon filter units, laminar flow hoods, and biosafety cabinets. They protect users and products during chemical processes and laboratory work.

Fume hoods are essential in pharmaceutical manufacturing, microelectronics, and research labs where hazardous materials could compromise safety or process integrity.

Laminar Flow Hood

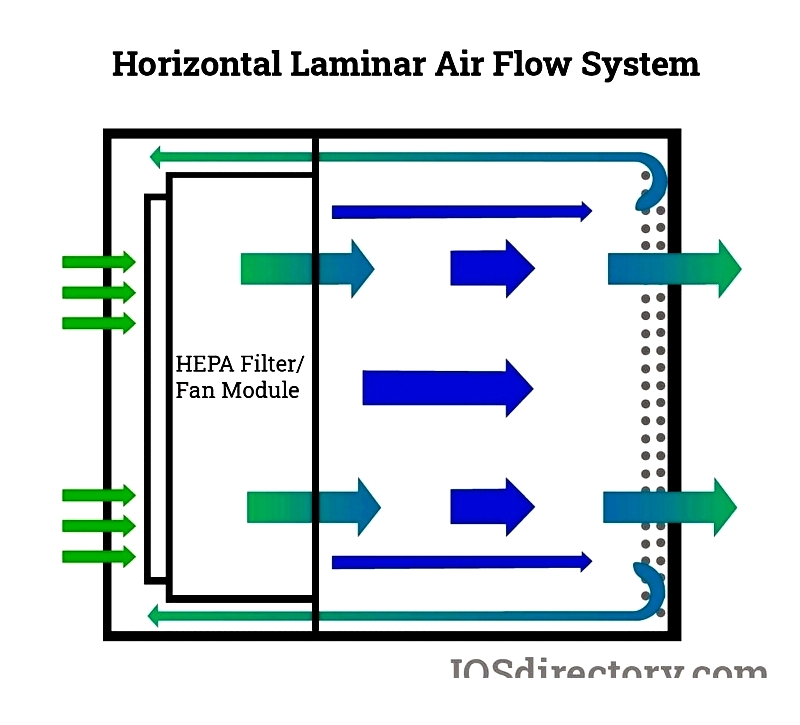

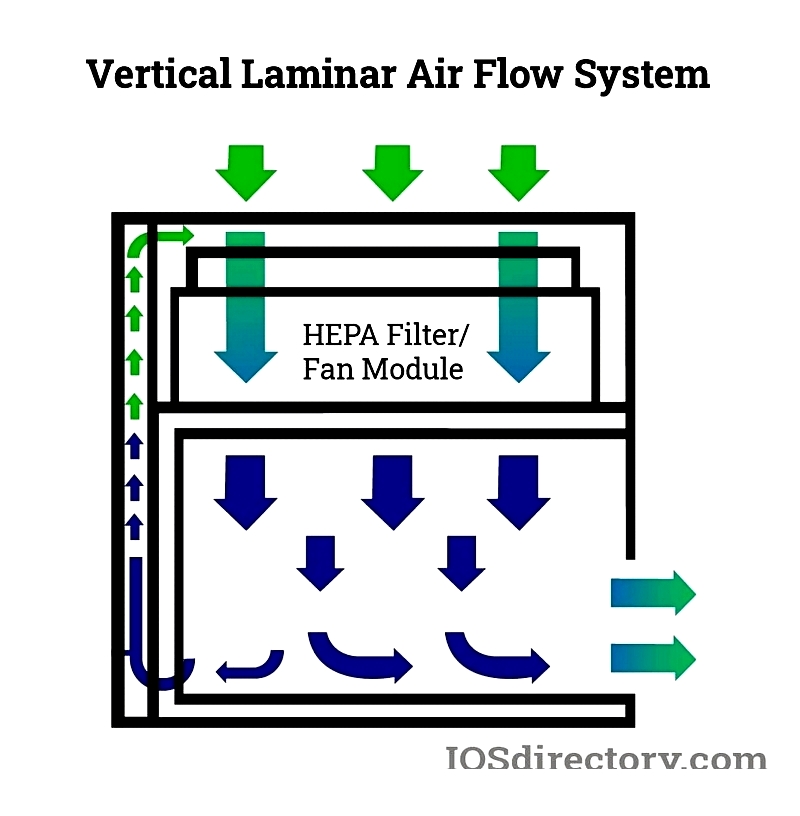

Laminar flow hoods create ultra-clean workspaces using HEPA-filtered air streams. They're ideal for sterile processes like tissue culture or pharmaceutical compounding. These hoods feature filter pads and high-performance fans that remove 99.97% of particulates.

Vertical flow hoods direct air downward, while horizontal models flow air across the workspace. The choice depends on particle sensitivity and workflow requirements.

Biosafety Cabinet

Biosafety cabinets provide secure handling of infectious agents using HEPA filters. Classified into three categories, they offer increasing protection levels. Class III cabinets enable safe manipulation of highly infectious agents for pharmaceutical and clinical research.

Vacuum Chamber

Vacuum chambers create controlled, air-free environments for testing and processing. Used in aerospace, medical, and semiconductor applications, they support outgassing and leak detection while meeting cleanroom standards.

Desiccator

Desiccators preserve sensitive items in moisture-free environments. Available in standard, vacuum, and gas purge models, they prevent humidity-related degradation in pharmaceutical and electronics cleanrooms.

Nitrogen Generator

Nitrogen generators produce ultra-pure nitrogen for cleanroom applications. They support operations in gloveboxes and metrology chambers, ensuring sample integrity and oxidation prevention.

Cleanroom Pass Thru

Pass thrus allow safe material transfer between cleanroom areas, reducing contamination risks. Available with HEPA filtration and UV sterilization, they're essential for pharmaceutical and semiconductor environments.

Cleanroom Door Swing

Cleanroom doors maintain sterile environments with tight sealing and antimicrobial surfaces. Automated models integrate with air showers and access systems for enhanced contamination control.

Lab Oven

Lab ovens provide controlled heating for cleanroom applications. Available in forced air and convection models, they support various thermal processing needs while maintaining compliance standards.

Cleanroom Air Shower

Air showers remove contaminants before personnel enter cleanrooms. These HEPA-filtered chambers maintain ISO compliance with programmable cycles and automated entry features.