Introduction

This article provides an in-depth exploration of hydraulic valves and their benefits.

Key topics covered include:

- Working Principles of Hydraulic Valves

- Classifications and Varieties of Hydraulic Valves

- Benefits and Limitations of Hydraulic Valves

- Additional Relevant Information

Chapter 1: Fundamental Principles of Hydraulic Valves

This chapter examines hydraulic valves in detail, focusing on their operational mechanisms and the techniques used for effective fluid flow management.

Understanding Hydraulic Valves

Hydraulic valves are critical mechanical devices that regulate hydraulic fluid flow in high-pressure systems, typically operating between 200 to 700 bar. These valves require durable construction materials to withstand such pressures. They employ various control methods, including physical, mechanical, electrical, hydraulic, and pneumatic systems for optimal performance.

Flow Control Techniques in Hydraulic Valves

Hydraulic valves utilize different methods to control fluid flow, such as:

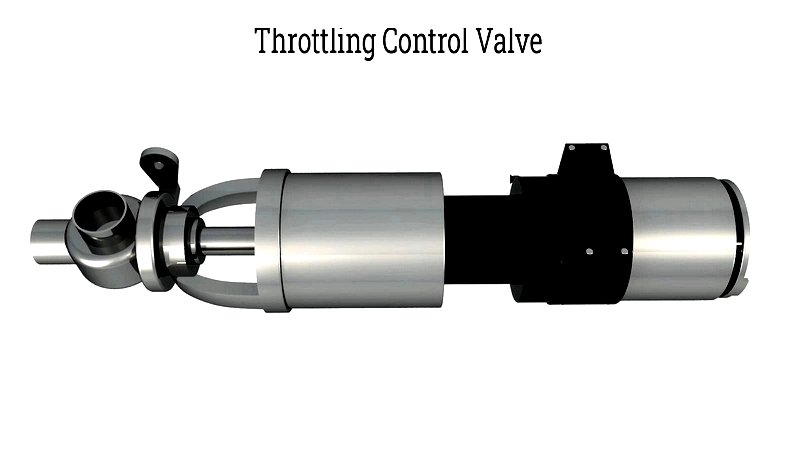

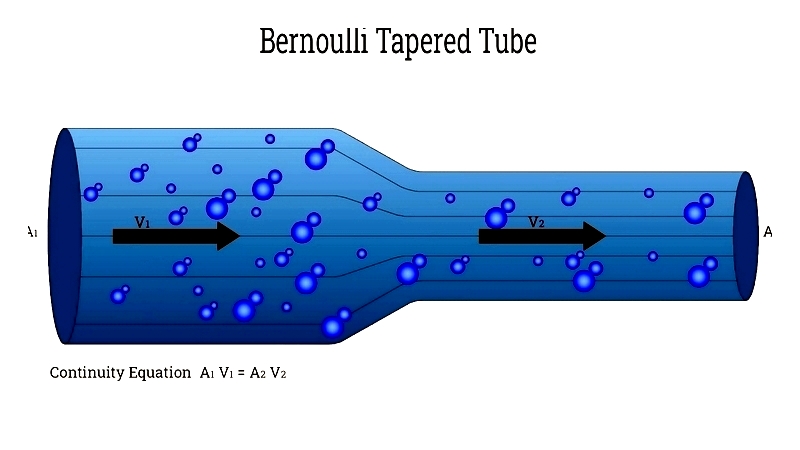

Throttling Flow Control

This method adjusts flow rates by altering the fluid passage size. Changing the valve's cross-sectional area modifies the flow rate, as demonstrated in the accompanying diagram. Bernoulli's principle effectively explains this process.

In tapered tubes, reducing the pipe diameter from d1 to d2 increases fluid velocity (V1 < V2), thereby raising the flow rate regardless of pipe angle. Any device that modifies the valve's cross-sectional area can effectively adjust the flow rate.

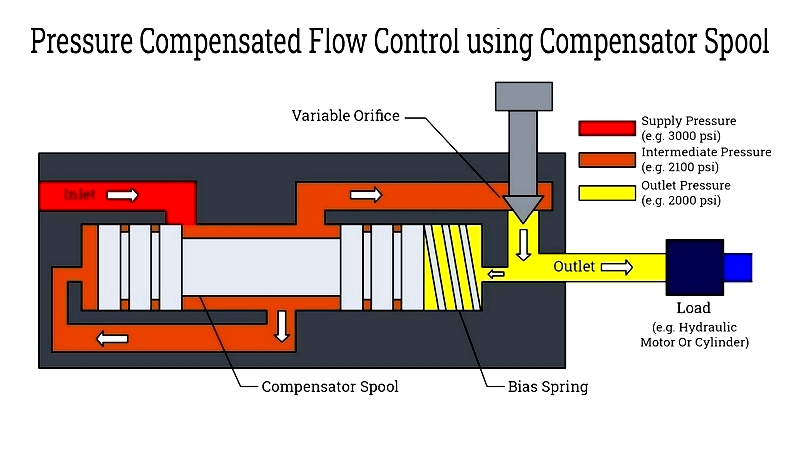

Pressure Compensated Flow Control

These specialized valves maintain consistent volumetric flow despite pressure variations in the system.

Featuring a variable orifice and integrated pressure compensation system, these valves adjust the inlet size dynamically through a spring-loaded compensator spool. The spool position, influenced by spring force, hydraulic load, and inlet pressure, ensures stable flow rates during pressure fluctuations.

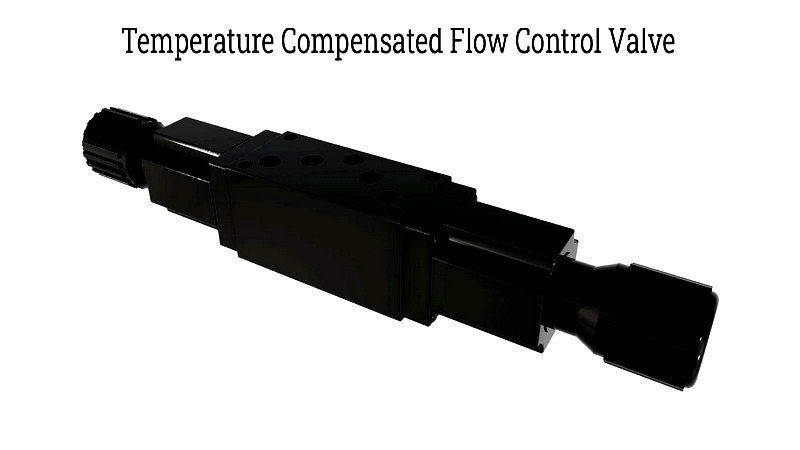

Temperature-compensated variants address precision issues caused by operational temperature changes through integrated temperature compensators.

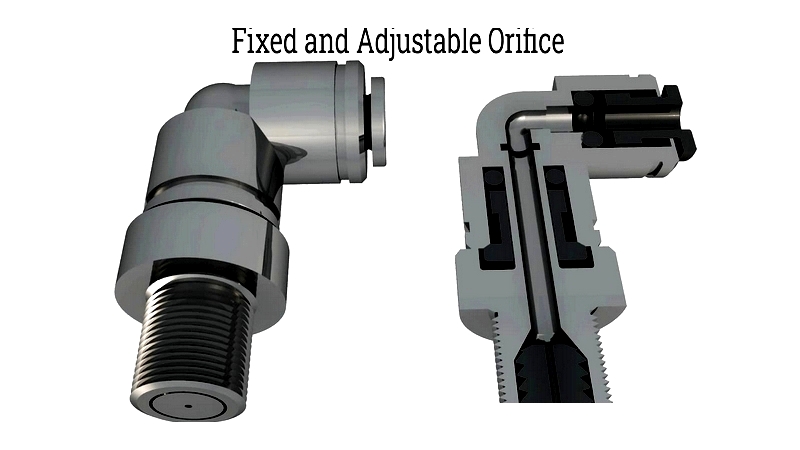

Fixed Flow Control

This simple approach uses a drilled opening in an otherwise blocked fluid channel, typically installed in series with the hydraulic pump.

Adjustable Flow Control

Priority valves represent a common adjustable mechanism, directing flow to specific outlets based on system demands. When pressure falls below a set threshold, these valves reduce flow to non-essential outlets through spring-loaded mechanisms that respond to system pressure changes.

Chapter 2: Hydraulic Valve Classifications and Types

Essential across multiple industries, hydraulic valves perform three primary functions that define their classifications:

- Flow rate regulation – Flow control valves

- Pressure monitoring and control – Pressure control valves

- Flow direction management – Directional control valves

Proper valve selection ensures system efficiency, reliability, and safety. This section details each valve class with specific examples, mechanisms, and industrial applications.

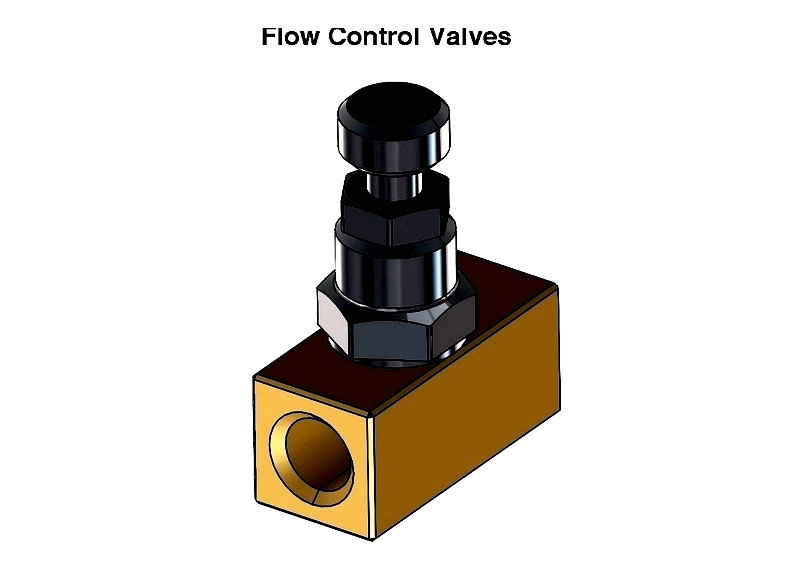

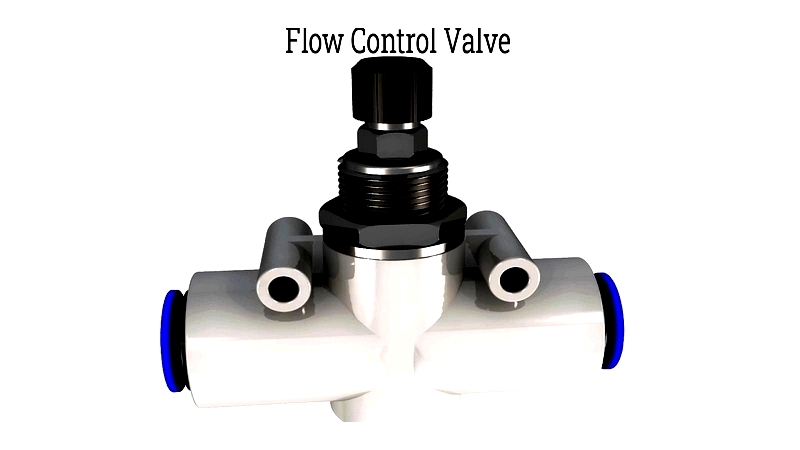

Hydraulic Flow Control Valves

These valves regulate hydraulic fluid flow rate, directly affecting actuator speed and system performance. They enable precise motion control in hydraulic cylinders and motors through adjustable orifices or gates.

For instance, they control press cylinder speeds in industrial applications. Flow rate adjustments directly impact actuator speed and power output, making proper valve selection crucial for balancing performance and efficiency.

Flow Control Valve Varieties

Classification based on internal mechanisms and control strategies includes:

- Ball valves – Basic flow control and isolation

- Needle valves – Precise flow adjustment for metering

- Diaphragm valves – Corrosive/abrasive fluid handling

- Butterfly valves – High-flow, low-pressure applications

Pressure Control Valves

Pressure regulation valves protect systems by maintaining safe pressure limits through various methods:

Pressure Valve Types

- Relief valves – Prevent overpressure damage

- Sequence valves – Ensure operational order

- Counterbalance valves – Maintain load position

- Reducing valves – Maintain lower branch pressures

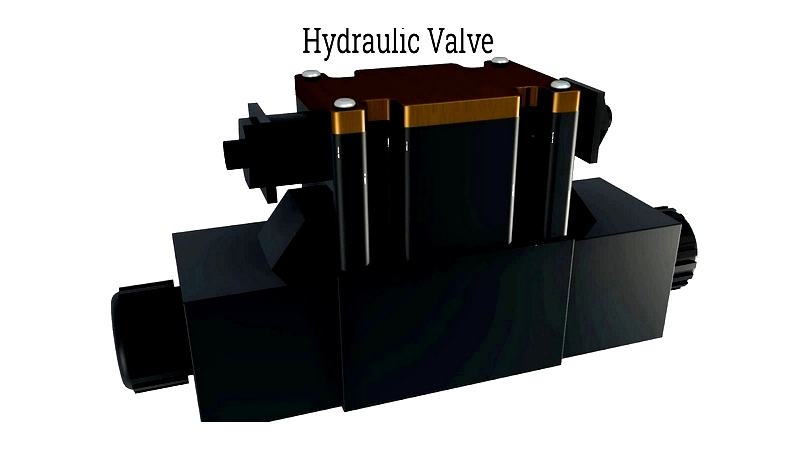

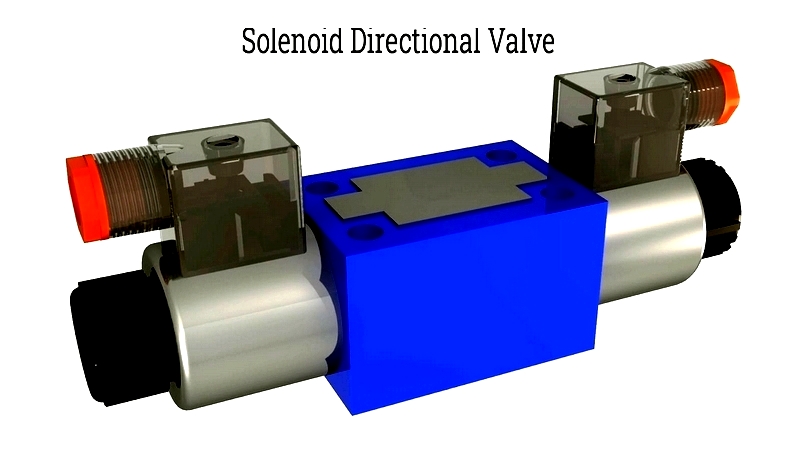

Directional Control Valves

These valves route hydraulic fluid to control actuator movement, essential for coordinated operation in industrial systems.

Directional Valve Types

- Multi-way valves (2-way to 4-way)

- Check valves (prevent backflow)

- Solenoid valves (electronic control)

Solenoid Valve Considerations

- Port configuration: Matches system complexity

- Flow capacity: Matches system requirements

- Material compatibility: Suits operational environment

Understanding these valve classifications enables optimal system design, enhancing performance and safety across applications.