Introduction

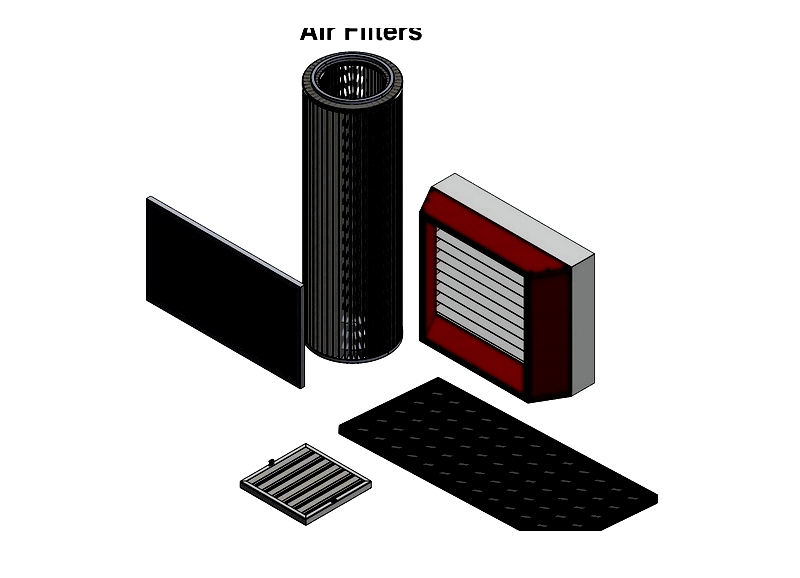

This article provides an in-depth exploration of air filters.

Continue reading to discover more about key topics including:

- What is an air filter?

- Types of air filter media

- Performance of air filters

- Types of air filters

- And much more...

Chapter 1: Overview of Air Filters

Air filters play a crucial role in removing airborne contaminants like particles, pollutants, and microorganisms, which can pose serious health risks and environmental damage. In industrial settings, they are essential for maintaining product quality, protecting equipment, and reducing waste.

Cleanrooms employ high-efficiency particulate air (HEPA) filters, which are about 100 times more effective than standard furnace filters, along with airflow management strategies to control particle levels. Exhaust and stack gases are filtered before release. Air filters are used in residential furnaces, offices, laboratories, medical facilities, microelectronics manufacturing, and aerospace applications.

Air filters effectively capture various airborne contaminants including dust, smoke, aerosols, odors, viruses, and toxic gases. These pollutants can worsen respiratory conditions, allergies, and other health issues.

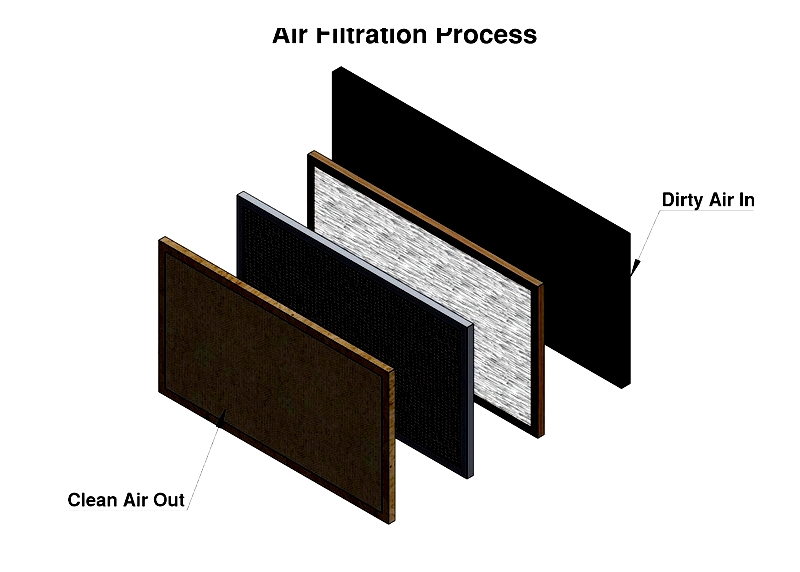

How Do Air Filters Work?

Air filters operate by drawing contaminated air through a filter medium with tiny openings. Particles larger than these openings are trapped, reducing their concentration in the air. As particles accumulate, filtration efficiency improves. Regular replacement or cleaning prevents clogging and maintains optimal performance.

Chapter 2: Types of Air Filter Media

Filter media are the core components of air filters, capturing airborne particles in residential, commercial, and industrial settings. They improve indoor air quality and protect HVAC systems. Typically made of synthetic fibers or engineered materials with microscopic perforations, filter media are housed in frames or cartridges integrated into various air filtration systems.

Air filter media fall into two main categories: pleated and non-pleated, each with distinct performance characteristics and applications.

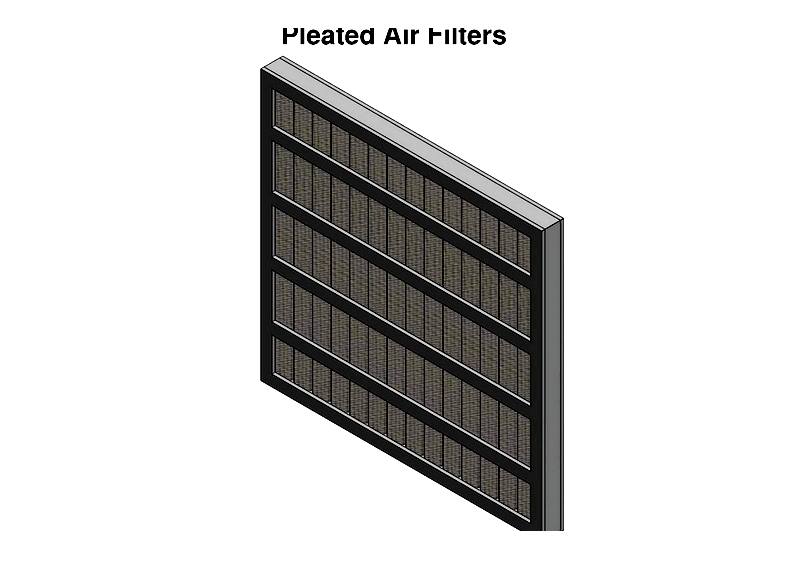

Pleated Air Filter

Pleated air filters feature folds that increase surface area, enhancing dust-holding capacity and efficiency while extending service life. Housed in rigid frames, they perform well in HVAC systems across various settings.

With higher MERV ratings (typically MERV 8-13+), pleated filters effectively capture fine particles like dust mites, pollen, and mold spores. They're ideal for environments requiring improved air quality, such as medical facilities and homes with allergy sufferers.

Made from durable materials like polyester, pleated filters may restrict airflow if improperly sized, potentially increasing energy consumption. Though more expensive initially, they offer longer service intervals and superior performance.

Non-Pleated Air Filter

Non-pleated (flat panel) filters handle higher air pressures and flow rates. Made from fiberglass or electrostatic cotton, they offer cost-effective basic filtration for larger particles.

With lower MERV ratings (MERV 1-4), non-pleated filters require more frequent replacement and are less suitable for environments needing high-efficiency filtration or allergen control.

Common materials used in air filter media include:

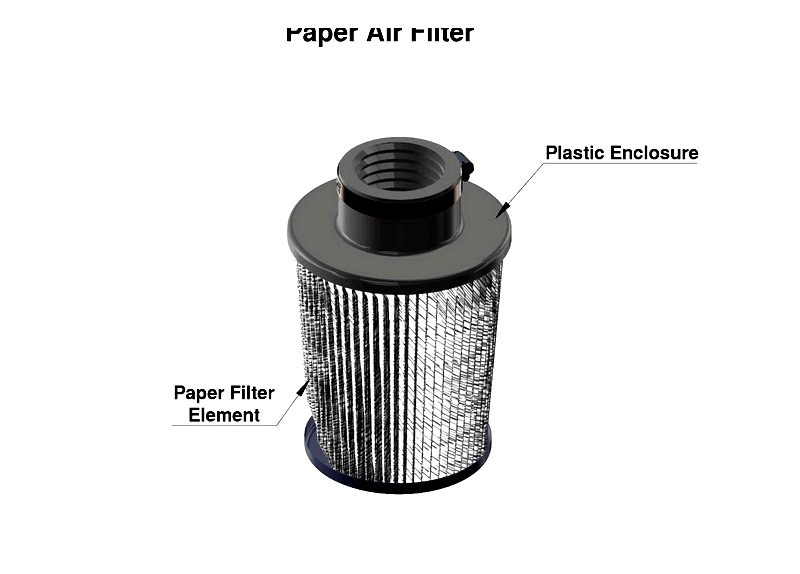

Paper Air Filter

Paper filters, made from compressed wood pulp fibers, offer affordable basic filtration. Pleated designs enhance strength and efficiency for applications like automotive and furnace filters. Regular replacement maintains performance.

Foam Air Filter

Foam filters, made from open-cell polyurethane or polyester, are rated by Pores Per Inch (PPI). Higher PPI means finer filtration but reduced airflow. Ideal for pre-filters and automotive applications, they're washable and reusable.

Carbon Air Filter

Activated carbon filters specialize in gas-phase filtration and odor removal. Their porous structure adsorbs VOCs, smoke, and chemical contaminants. Often paired with HEPA filters, they're essential for odor-sensitive environments.

Aluminum Air Filter

Aluminum mesh filters serve as durable pre-filters in industrial systems. Corrosion-resistant and washable, they're ideal for high-temperature or corrosive environments like HVAC systems and welding facilities.

Fiberglass Air Filter

Fiberglass filters provide basic particle filtration at low cost. With MERV 1-4 ratings, they're suitable for general residential use but less effective for fine particle control. Frequent replacement is necessary.

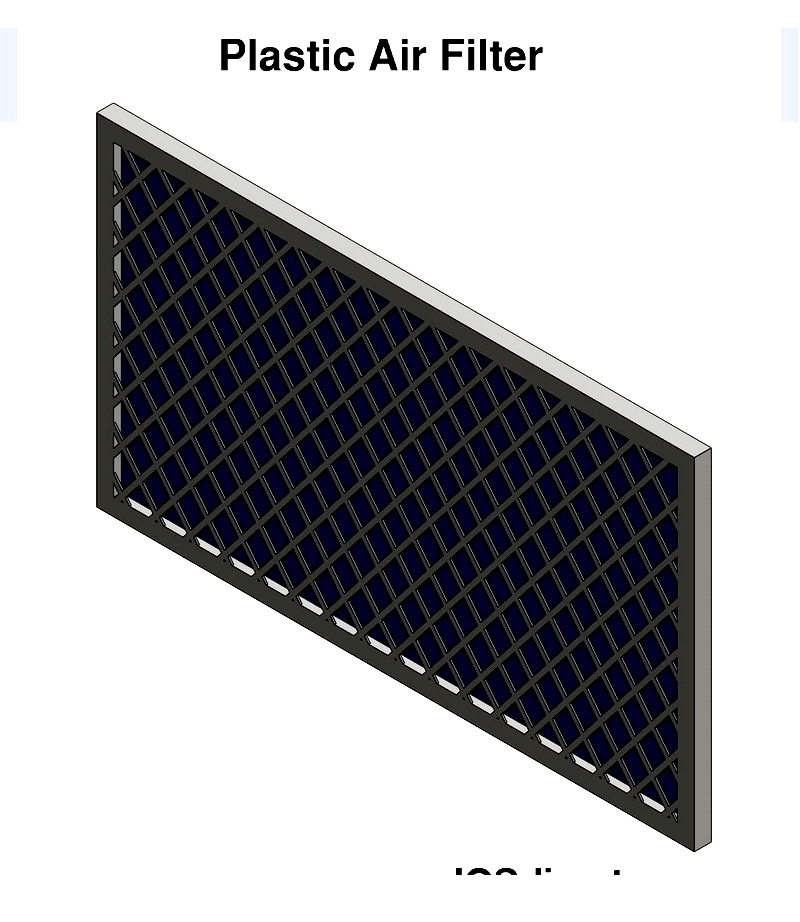

Plastic Air Filter

Made from synthetic fibers like polypropylene, plastic filters offer chemical resistance and durability. Often electrostatically charged, they're suitable for industrial and cleanroom applications where washable, reusable filters are preferred.