Introduction

This guide covers everything about plastic tubing manufacturing and applications.

You'll discover:

- What Plastic Tubing Is

- Plastic Tubing Applications

- Plastic Tubing Manufacturing Process

- Plastic Tubing Design

- And more...

Chapter One – Understanding Plastic Tubing

Plastic tubing combines polymers with various chemicals to create materials ranging from rigid to flexible. Since its introduction in the 1950s, it has transformed industrial processes and become essential across numerous applications.

Known for its versatility, plastic tubing comes in various wall thicknesses, diameters, tolerances, and strengths. Manufacturers use different materials to meet specific application requirements.

Chapter Two – Plastic Tubing Applications

Plastic tubing's flexibility, chemical resistance, durability, and adaptability make it indispensable across industrial, commercial, and residential sectors. It delivers reliable performance in manufacturing, agriculture, healthcare, automotive, and food processing. Compared to traditional materials like steel and copper, plastic tubing offers superior tensile strength, lightweight construction, corrosion resistance, and cost-effectiveness.

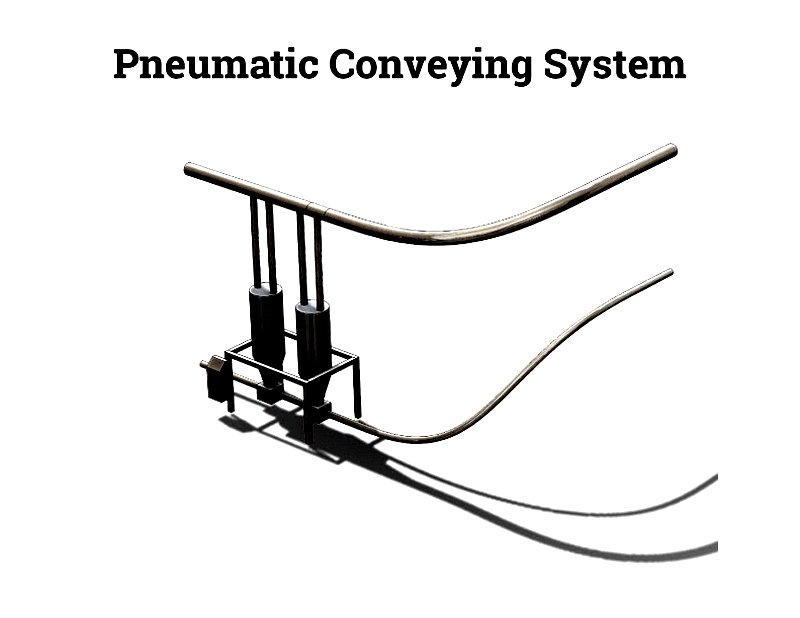

Pneumatic Tubing

Specialty pneumatic tubing handles compressed air distribution in automation systems. Made from polyurethane or nylon, it withstands industrial pressures and temperature extremes (-20°C to 60°C), making it ideal for robotics and factory automation.

Mailing Tubing

Durable polyethylene mailing tubes protect documents during shipping. Their crush-resistant design and tamper-evident caps ensure secure delivery of sensitive materials.

Banking Tubing

Banking systems use thick-walled plastic tubing for secure document transport. Smooth interiors prevent blockages while meeting strict safety standards for financial transactions.

Farming Tubing

Agricultural tubing supports irrigation and livestock watering. Its UV resistance and lightweight design make installation efficient across large farms.

Liquid Tubing

Food-grade tubing meets strict sanitation standards for beverage and water lines. Chemical-resistant variants handle aggressive fluids in industrial settings.

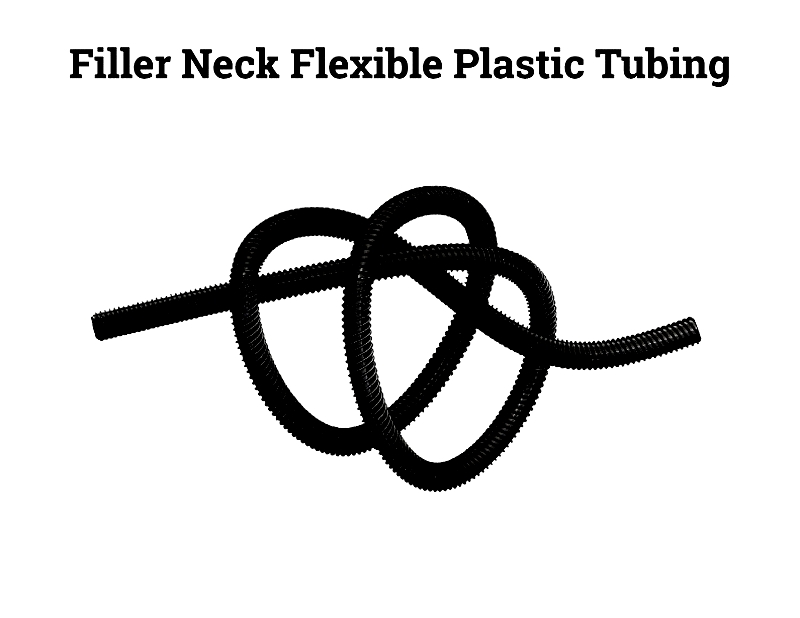

Automotive Tubing

Reinforced nylon tubing replaces metal in fuel and coolant systems. Its vibration absorption and weight reduction benefit modern vehicle design.

Marine Tubing

Marine-grade PVC tubing resists saltwater corrosion. UV-stabilized versions withstand harsh weather conditions in boating applications.

Medicinal Tubing

Medical tubing meets biocompatibility standards for IV lines and catheters. Sterile packaging ensures safety in healthcare settings.

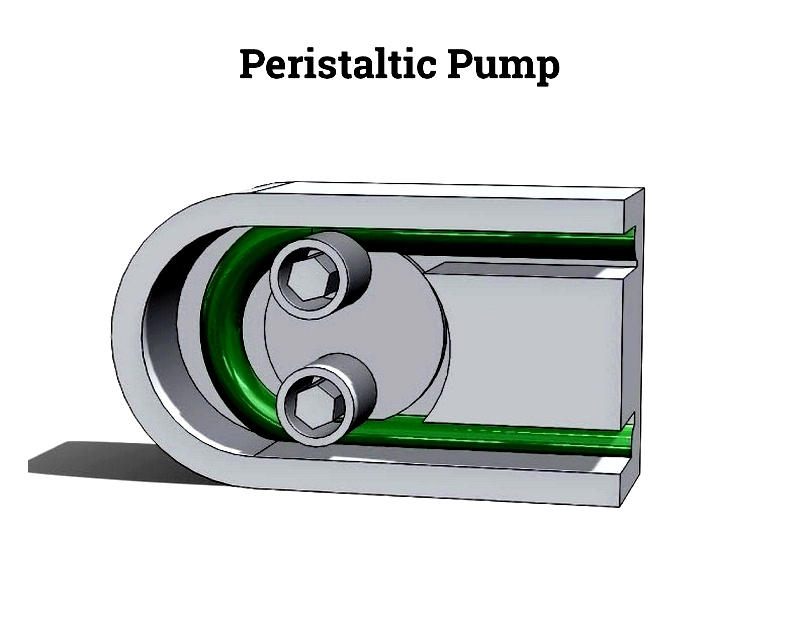

Peristaltic Pumps

These pumps use flexible tubing for contamination-free fluid transfer. Material selection impacts chemical resistance and pump longevity.

Additional Applications

Plastic tubing serves HVAC, aquaculture, and laboratory needs. Selection factors include material compatibility, pressure ratings, and regulatory certifications.

Chapter Three – Plastic Tubing Manufacturing

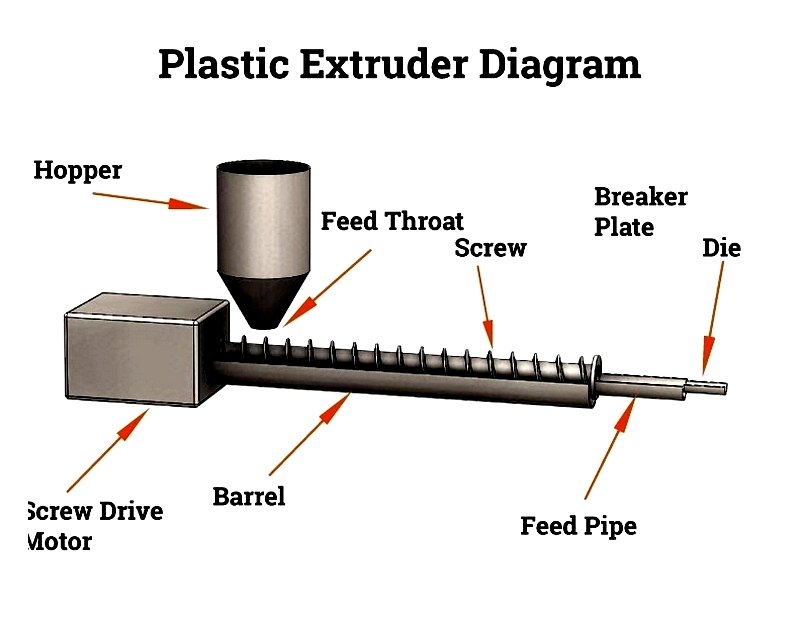

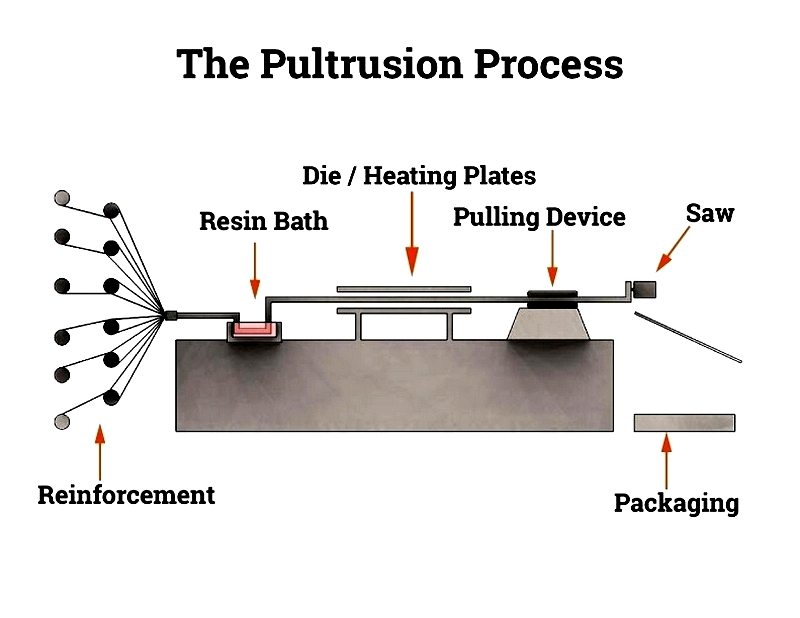

Manufacturers primarily use extrusion and pultrusion processes. Extrusion forces molten plastic through dies, while pultrusion pulls reinforced fibers through shaping tools.

Plastic Extrusion

The process begins with polymer pellets melting in a barrel. Computer-controlled systems ensure consistent wall thickness for medical, industrial, and food-grade tubing.

Coextrusion combines materials for specialized applications like pharmaceutical tubing.

Plastic Pultrusion

This method produces fiber-reinforced tubing with high strength-to-weight ratios. It's ideal for corrosive environments and structural applications.

Material Options

Different plastics offer unique properties for specific applications:

Acrylic Tubing

Optically clear for laboratory and display uses. Half the weight of glass with superior impact resistance.

PVC Tubing

Economical choice for plumbing and irrigation. Resists chemicals and meets food safety standards.

CPVC Tubing

Handles higher temperatures than standard PVC. Ideal for hot water systems and chemical processing.

Fiberglass Tubing

Pultruded FRP tubing offers corrosion resistance for electrical and structural applications.

Nylon Tubing

Durable