Introduction

This article provides an in-depth exploration of thermal shocks.

It covers key topics including:

- Principles of Thermal Shocks

- Types of Thermal Shock Chambers

- Applications and Benefits of Thermal Shock Chambers

- And More...

Chapter 1: Understanding the Principles of Thermal Shocks

This chapter examines thermal shock chambers in detail, focusing on their design, construction, and operational mechanisms.

Defining Thermal Shock Chambers

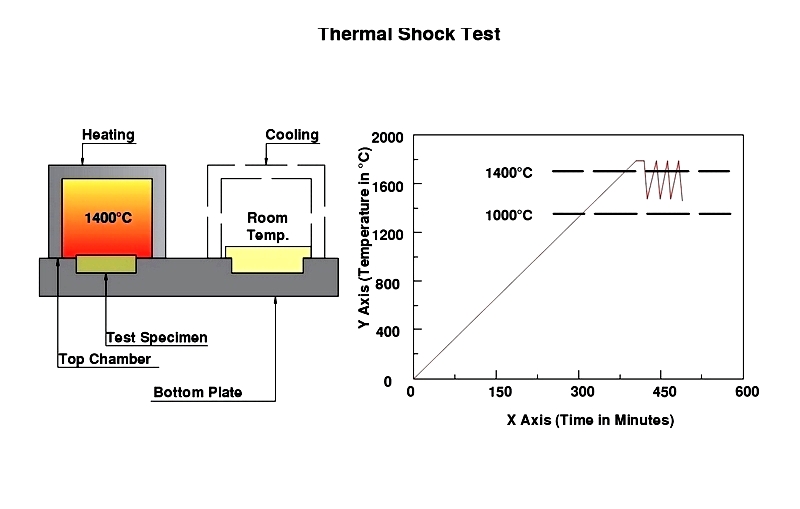

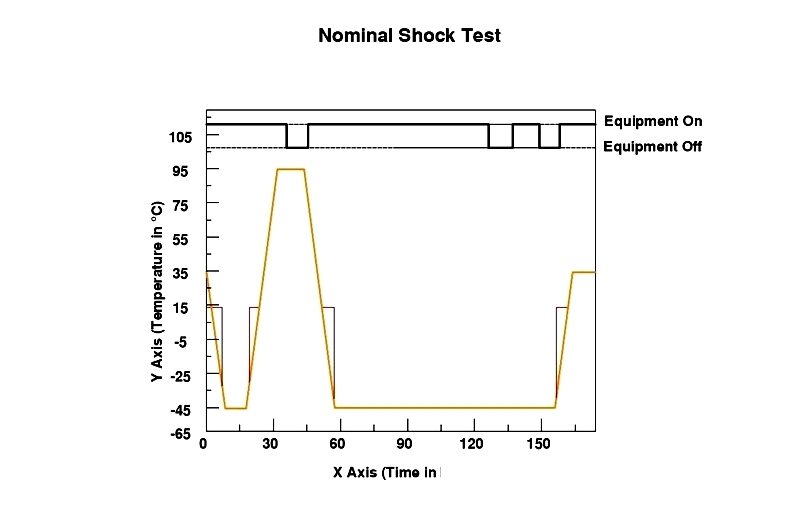

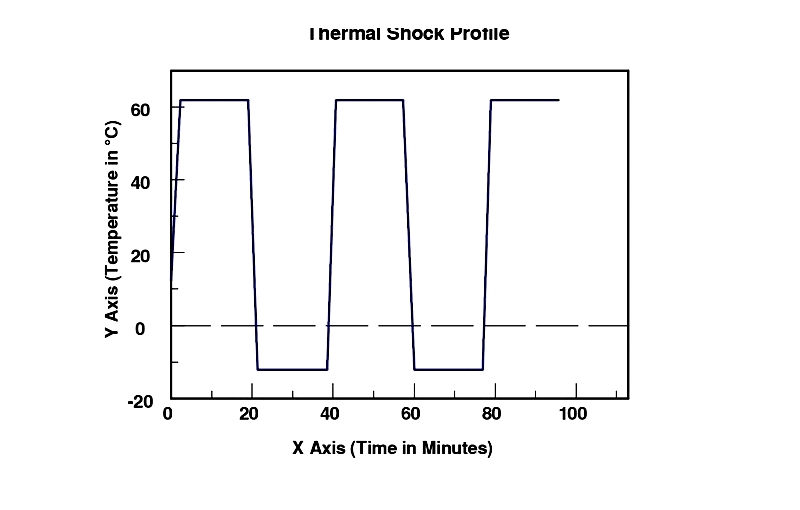

Thermal shock chambers are specialized climate chambers that test materials under extreme temperature variations. They rapidly alternate between high and low temperatures to identify defects or potential failures, particularly important in electronics where early failures can be critical.

Materials are placed in a mobile basket that quickly moves between hot and cold zones, completing cycles in about 10 seconds. These chambers typically feature multiple compartments and follow standardized testing protocols.

The tests evaluate product durability under thermal stress. Materials may experience uneven heating or cooling, causing volume changes and mechanical stress that could lead to failure.

These tests are crucial for assessing electronic reliability in critical fields like aerospace. Thermal shocks exceeding material limits can cause component failures, especially with mismatched thermal expansion coefficients.

Using thermal shock chambers helps identify product flaws before manufacturing, allowing necessary adjustments to optimize performance.

Environmental Chambers

Thermal shock chambers are a type of environmental chamber that simulates various physical and climatic conditions. They create controlled environments for testing product properties under different temperature, humidity, and pressure conditions.

Environmental testing evaluates product quality through various assessments, checking for issues like corrosion or emissions.

Thermal Shock Chamber Construction

Key components include:

Cabinet Structure

The cabinet features galvanized steel construction with polyurethane foam and glass wool insulation for thermal efficiency. It includes a steel base with support feet and casters for mobility.

High Temperature Zone

Located in the upper section, this zone uses 304-grade stainless steel for durability. It includes a circulating air system with heating elements for rapid temperature transitions.

Low Temperature Zone

Positioned at the bottom, this zone also uses 304 stainless steel. It features a cooling system with an evaporator for low-temperature testing.

Transfer Basket

The stainless steel basket moves samples between zones using a cylinder-powered mechanism for efficient sealing during transitions.

Materials Used

Primary materials include:

Galvanized Steel

Hot-dip galvanized steel provides corrosion resistance, protecting the cabinet structure.

304 Stainless Steel

This alloy offers excellent corrosion resistance and durability for chamber components.

Operational Principles

Key functions include:

Temperature Control

The chamber maintains precise temperature distribution using refrigeration systems and programmable controls.

Humidity Management

Humidity is controlled through electric humidifiers and dehumidification systems.

Technical Specifications

Typical specifications include:

- Volume: 60L to 120L

- Temperature Ranges: -80°C to 220°C

- Loading Capacity: 20kg to 100kg

- Power Rating: 8kW to 14kW

Selection Criteria

important considerations:

Temperature Range

Chambers vary from single-stage (-40°C) to dual-stage (-70°C) systems.

Transition Rates

Typical rates range from 6°C/min to 10°C/min.

Chamber Size

Sample size should not exceed one-third of chamber volume.

Sample Weight

Must not exceed rated capacity.

Chapter 2: Types of Thermal Shock Chambers

Thermal shock chambers come in several configurations for different testing needs.

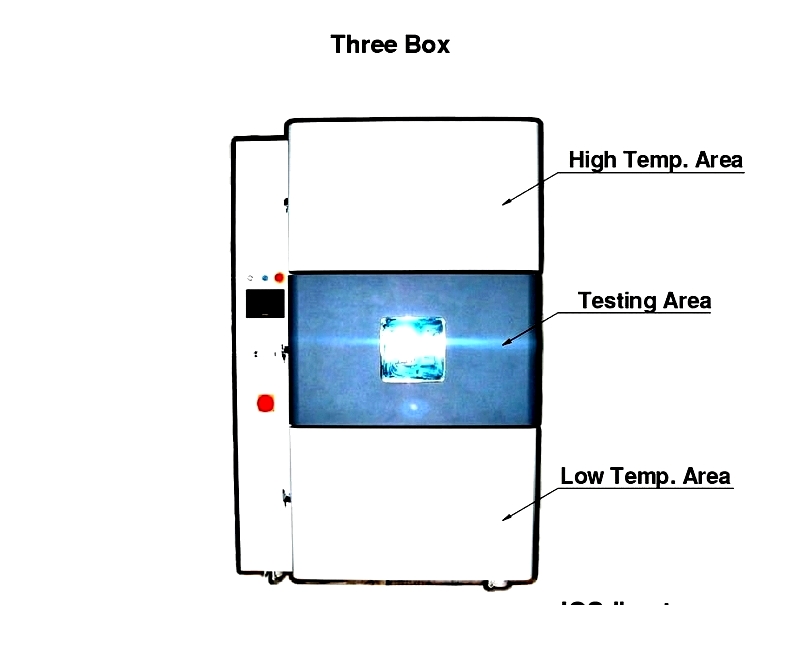

Three-Box Chambers

Feature fixed test zones with high throughput capacity.

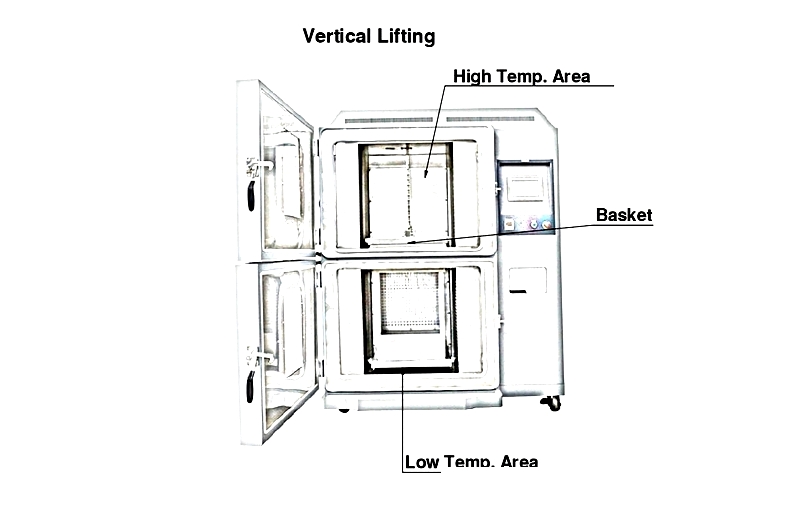

Vertical Lift Chambers

Compact design with vertical temperature zone arrangement.

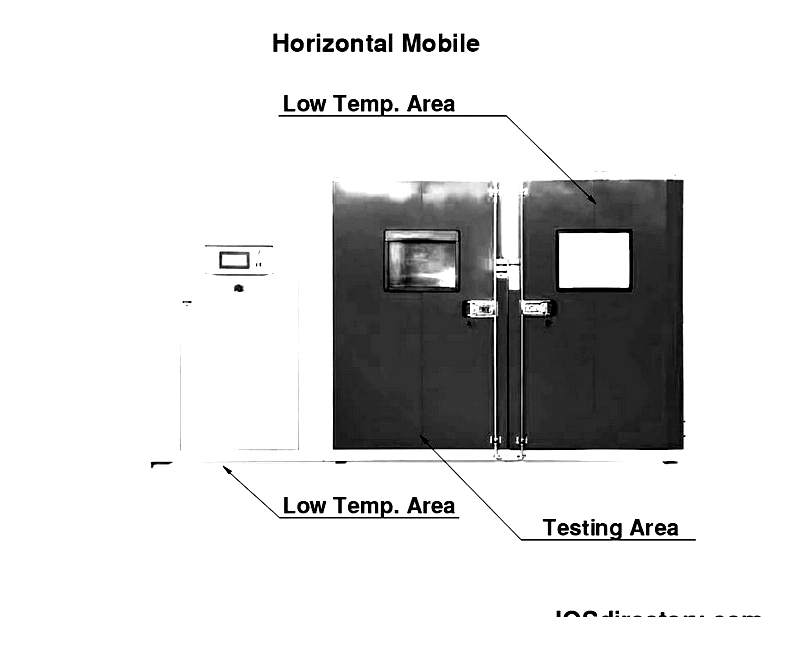

Horizontal Mobile Chambers

Ideal for larger components with side-to-side transfer.

Table 1: Comparison of Thermal Shock Chamber Types

Selection Guidelines

Consider temperature range, sample size, throughput needs, and available space when choosing a chamber.