Introduction

This article provides an in-depth examination of gear reducers and their applications.

You will explore key topics including:

- What is a Gear Reducer

- Types of Gear Reducers

- How to Choose a Gear Reducer

- How Gear Reducers Work

- And Much More...

Chapter One – What is a Gear Reducer?

A gear reducer is a mechanical device designed to reduce input rotation speed while increasing output torque. It achieves this through interconnected gears, where a high-speed input shaft engages with multiple gears to adjust speed and torque. The gear arrangement and quantity depend on the required speed and torque characteristics for specific applications.

Gear reducers are essential when the driving gear is smaller with fewer teeth than the driven gear. This differs from overdrive systems where the driving gear is larger with more teeth.

In automotive applications, gear reducers are crucial for converting high-speed engine rotation into slower wheel motion, allowing tires to effectively utilize engine power safely and efficiently.

Chapter Two – How Gear Reducers Work

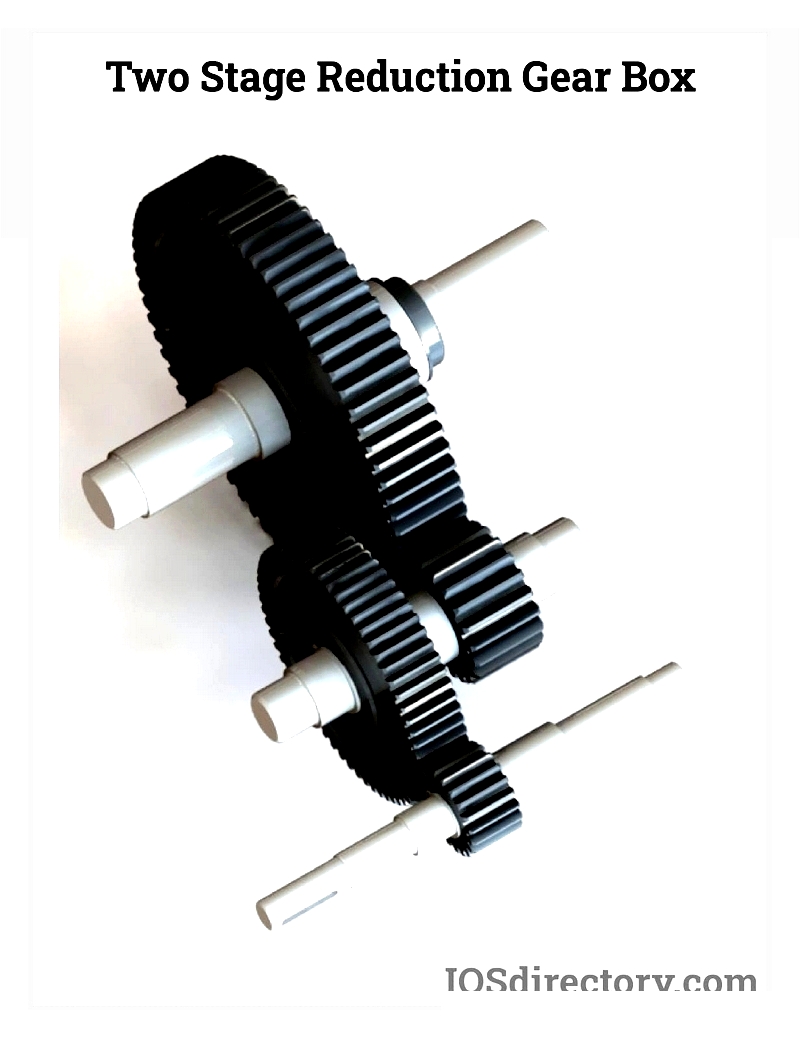

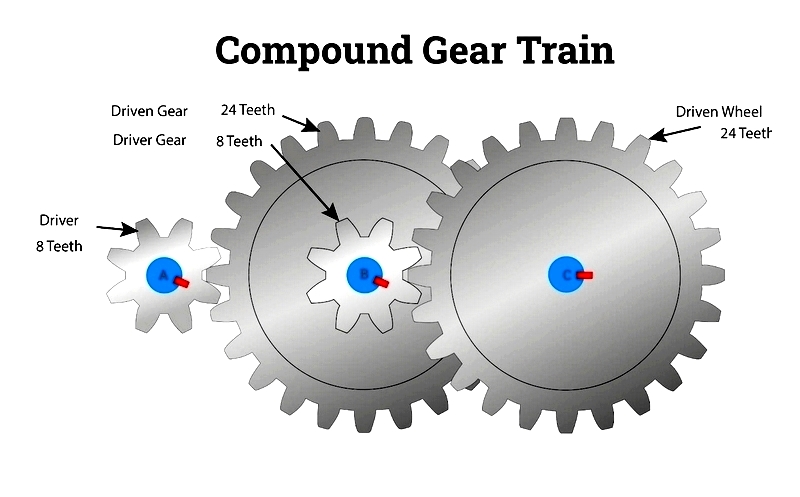

Gear reducers, also called reduction gears or gearboxes, are vital components in industrial machinery. They convert high-speed motor rotation into lower output speeds while increasing torque. This adjustment enables optimal machine performance across various applications, from conveyor systems to robotics. Typically consisting of a larger driven gear and smaller drive gear, they form the core speed reduction mechanism.

When a larger gear drives a smaller one, the smaller gear completes two rotations per single rotation of the larger gear, increasing speed but reducing torque. Conversely, a smaller driving gear increases torque while reducing speed - ideal for industrial systems requiring high force at low speeds.

Gear reduction works through precise ratios that match input/output characteristics with application requirements. By controlling gear interactions, reducers ensure reliable energy transfer between motors and machinery across industries.

The Process of a Gear Reducer

Gear Ratio

The gear ratio determines gear reducer performance by comparing drive and driven gear characteristics. For example, a 2:1 ratio means output speed halves while torque doubles. This principle extends to complex systems like planetary gear reducers, where multiple gear pairs achieve high torque in compact designs.

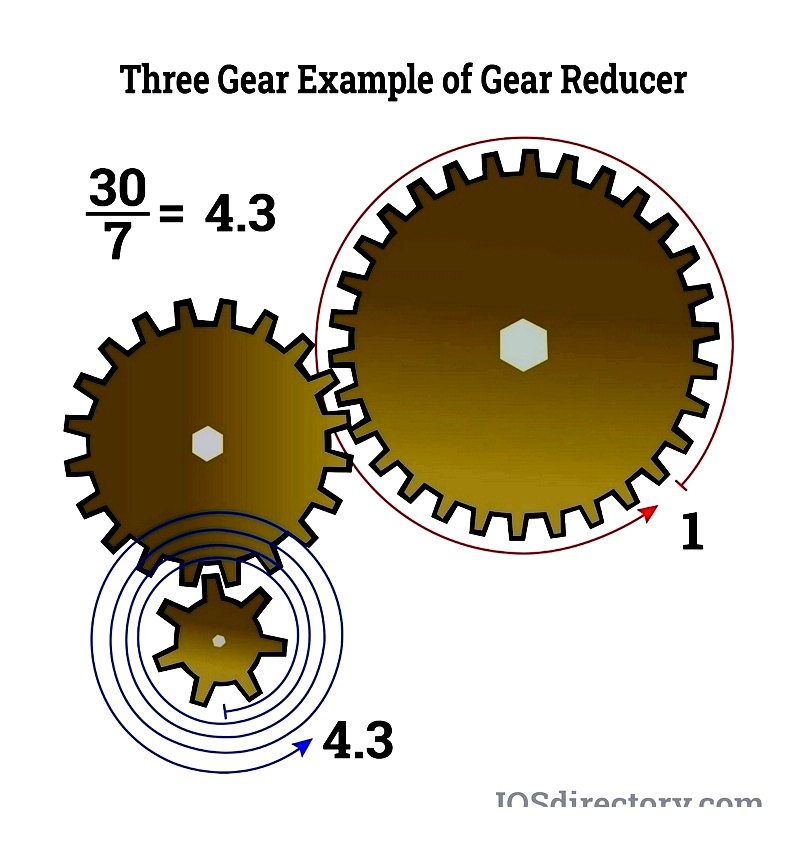

Intermediate idler gears don't affect the ratio but may change rotation direction. To calculate ratio, compare teeth counts - a 7-tooth drive gear and 30-tooth driven gear create a ~4.3:1 ratio. Proper ratio selection ensures efficient power matching for specific applications.

Gear Reducer Torque

Torque represents rotational force modified by gear reducers while maintaining power levels. Different gear types (helical, spur, bevel, worm) enable customized speed-torque balances for various industrial needs. The gear ratio directly impacts output torque, protecting systems from motor overload.

Drive Gear

Drive gears modify shaft speed, torque, or direction. A small drive gear meshing with a larger output gear enables speed reduction. Worm drives, like the silver shaft shown below, provide compact high-ratio reduction with non-reversing benefits for safety-critical applications.

Driven Gear

The driven gear delivers adjusted torque/speed to applications. Designs vary (helical for quiet operation, bevel for axis changes, planetary for compact high-load). In compound systems, multiple driven gears can synchronize outputs for manufacturing processes.

Common Types of Gear Reducers and Their Applications

Major reducer types include: Helical (quiet, efficient for precision systems), Worm (high-ratio for conveyors/lifts), and Planetary (compact high-torque for robotics). Selection depends on torque, speed, mounting, and duty requirements.

How to Select the Right Gear Reducer

Consider torque, reduction ratio, mounting, size, power source compatibility, backlash, efficiency, lubrication, and noise. Manufacturer support helps match reducers to specific industrial needs, improving efficiency and lifespan while reducing downtime.