Introduction

This article provides a comprehensive examination of compression springs.

Topics covered include:

- Principles of Compression Springs

- Manufacturing Processes and Materials for Compression Springs

- Types of Compression Springs

- Applications and Advantages of Compression Springs

- Common Issues with Compression Springs

- And more...

Chapter 1: Understanding the Principle of Compression Springs

This chapter explores the fundamentals of compression springs and key considerations for selecting the appropriate type.

Introduction to Compression Springs

Compression springs, also known as coil springs, store energy when compressed. These helical, open-coiled springs resist compressive forces and shorten under load to absorb significant potential energy.

When the load is reduced or removed, compression springs return to their original shape and length due to stored energy. Unlike extension springs, compressed coils remain in contact when loaded.

Design and Functionality of Compression Springs

Understanding spring mechanics, particularly Hooke's Law, is essential for designers and engineers. This principle states that deformation force is proportional to the amount of deformation, explaining why greater force is needed to compress a spring further.

The spring constant, measured in Newtons per meter or pounds per inch, determines the required deformation force. A higher constant indicates a stiffer spring, influenced by wire diameter, coil diameter, free length, and number of active coils.

Accurate spring constant calculation is crucial for optimal performance. An excessively high constant or overly thin wire may cause spring failure. Precision manufacturing ensures stability and prevents damage through carefully calibrated coiling machines.

Key Considerations When Selecting Compression Springs

Several factors should be evaluated when choosing compression springs:

Types of Compression Spring Ends

Compression springs feature various end types, including standard and custom designs such as open, closed, ground, and ungrouded ends. These configurations can affect spring rate despite consistent wire size, coil count, and outer diameter (OD).

Characteristics of Closed Ends

Closed-end compression springs stand upright on flat surfaces due to their closed terminal coils. They are cost-effective and simple to produce, requiring minimal processing. Additional support may be needed for springs with high slenderness ratios.

Features of Ground Ends

Ground end compression springs, a closed-end variant, have precisely ground ends for dimensional accuracy. This precision increases production time and cost but ensures proper slenderness ratios without requiring additional support.

Benefits of Double Closed Ends

Double closed end compression springs feature two closed terminals, similar to closed and squared ends. All coils remain in contact, enhancing stability and allowing higher slenderness ratios. Reinforced ends prevent buckling, often at lower costs than other end types.

Details on Open End

Open end compression springs are less common due to stability concerns without support. Their open, spaced coils make them suitable for applications where minimizing solid height is prioritized.

When paired with closed ends, open ends improve load distribution and reduce buckling risks. Ground ends increase manufacturing costs due to additional processing.

Not all manufacturers stock closed and ground ends as standard inventory. Custom end variations may include expanded coils for ring grooves, offset legs for alignment, or reduced coils for screw attachment.

Material Considerations for Compression Springs

Common spring materials include carbon steel and exotic alloys. Music wire, a high-carbon steel, is widely used, while stainless steel 302 offers superior corrosion resistance despite lower strength.

Nickel alloys are chosen for extreme temperature tolerance, corrosion resistance, and non-magnetic properties. Copper alloys like phosphor bronze and beryllium copper provide excellent electrical conductivity and corrosion resistance.

Physical Aspects of Compression Springs

Outer Diameter (OD): For springs inserted into holes, consider the outer diameter. If surrounded by internal components, measure their dimensions. OD expands under compression, which is crucial when used in tubes or bores. OD is measured across the outer coil edges.

Manufacturing processes may limit spring OD, affecting required assembly space. Manufacturers provide work-in-hole diameters based on anticipated OD expansion and tolerances, important for custom springs or catalog selections.

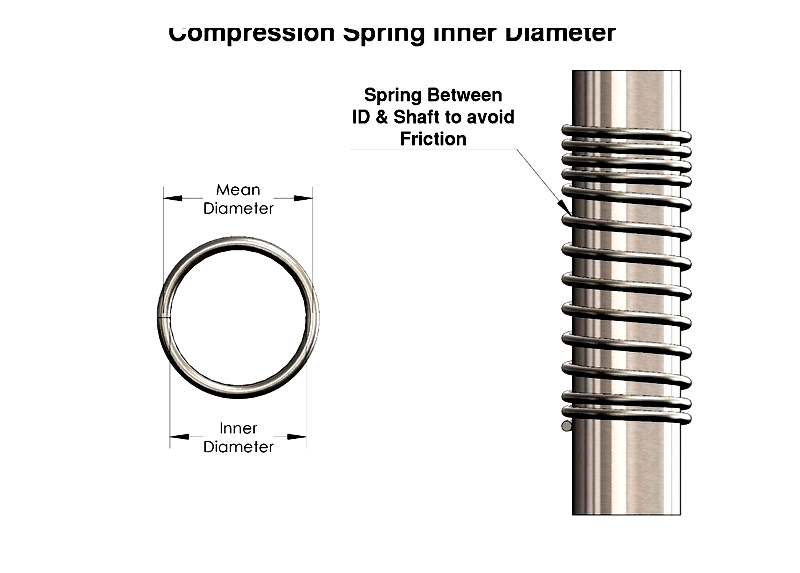

Inner Diameter (ID): For springs fitting over shafts or mandrels, account for the inner diameter. A minimum clearance of ten-thousandths of an inch prevents friction. ID is calculated by subtracting twice the wire diameter from the OD.

Free Length: Ensure the spring's free length exceeds available space for a preloaded state. Free length is the spring's length without compression, measured from end to end.

Solid Height: Wire diameter and total coil count determine solid height, ensuring loaded heights remain within limits.

Environmental factors like temperature and moisture affect spring performance. Higher-cost materials withstand extreme temperatures, increasing expenses.

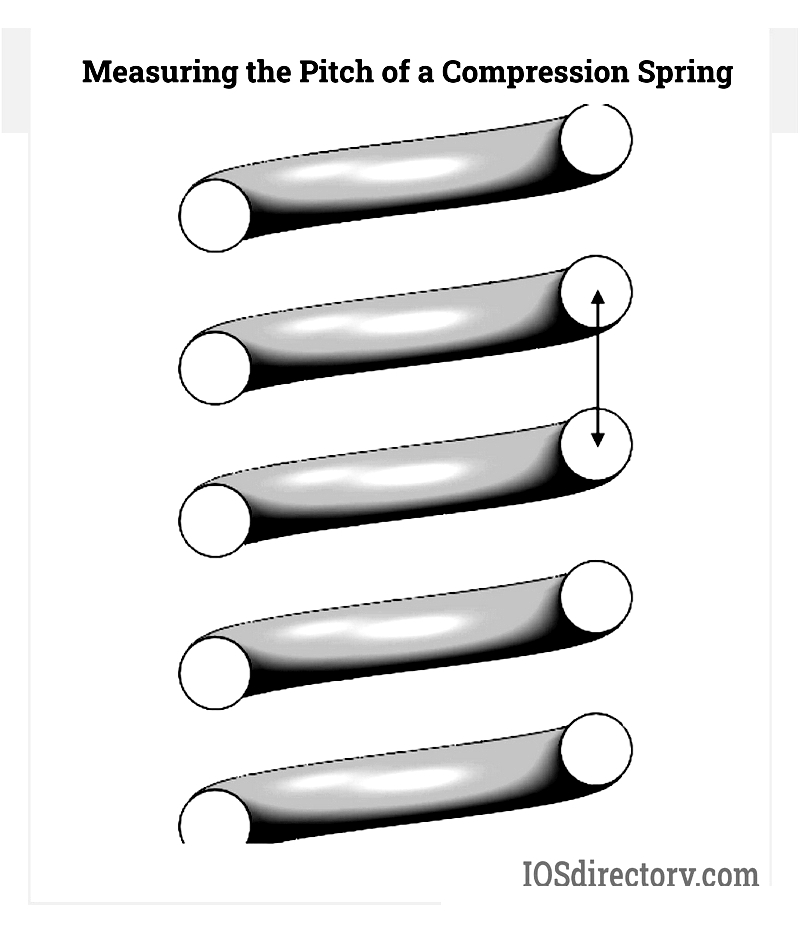

Spring Pitch: Pitch refers to the space between adjacent coils, measured from center to center. It is calculated by measuring coil gaps and adding wire thickness.

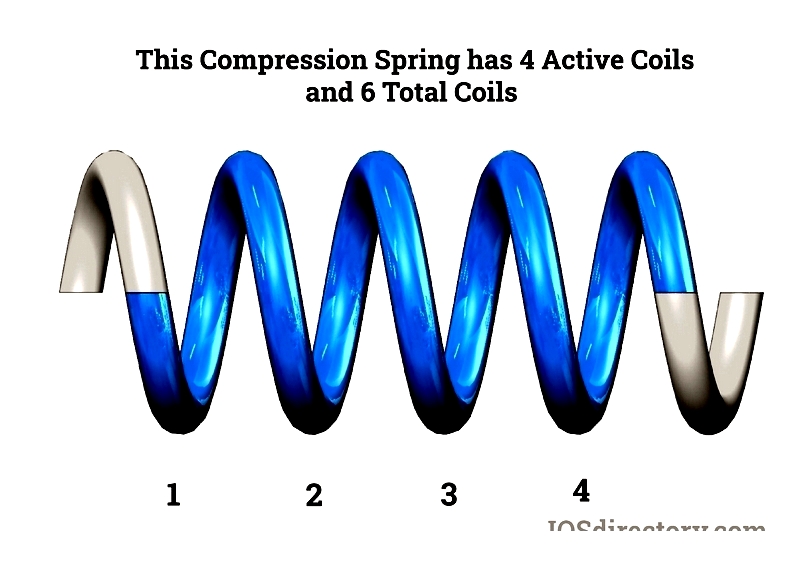

Active Coils: These coils compress and deflect under load, contributing to spring movement.

Total Coils: Includes both active coils and non-deflecting, closed coils without pitch.

Note the difference between total and active coil counts. Closed or ground-end springs have inactive ends, while open-end springs feature fully active coils.

Analyzing Compression Spring Loads

Consider a spring's load or travel requirements. The spring rate (spring constant) indicates the compression force needed per unit length, typically in pounds per inch (lbs/in). Designers use this to predict spring travel under load. Excessive compression may cause spring set, affecting length recovery after load removal, though functionality may remain intact.

Exploring Compression Spring Wire Diameters

Select appropriate wire diameter and material based on load, travel, and environmental needs. The Rockwell scale measures wire hardness, indicating flexibility and rigidity. This assessment evaluates indents from specific loads, revealing durability and stress performance.

Varieties of Compression Spring Wire

- High Carbon Spring Wire - Includes music wire and hard drawn wire, with Rockwell hardness of C31 to C60 and operating temperatures up to 250°F (121°C).

- Alloy Steel Wire - Composed of carbon, chromium, and silicon, with Rockwell hardness of C48 to C55 and temperature resistance up to 475°F (246°C).

- Stain