Introduction

This article provides detailed information about thermowells, covering topics such as:

- Thermowell basics: definition, operational principles, and importance

- Thermowell specifications, designs, and classification systems

- Key calculations for thermowells

- Material selection for thermowells

- Applications, advantages, and disadvantages of thermowells

- And more...

Chapter 1: The Significance of Thermowells

This chapter provides a comprehensive introduction to thermowells, explaining their definition and function. It examines their operational process and emphasizes their crucial role across various industries. Understanding these aspects helps readers appreciate how thermowells ensure accurate temperature measurements and maintain system integrity.

Understanding Thermowells

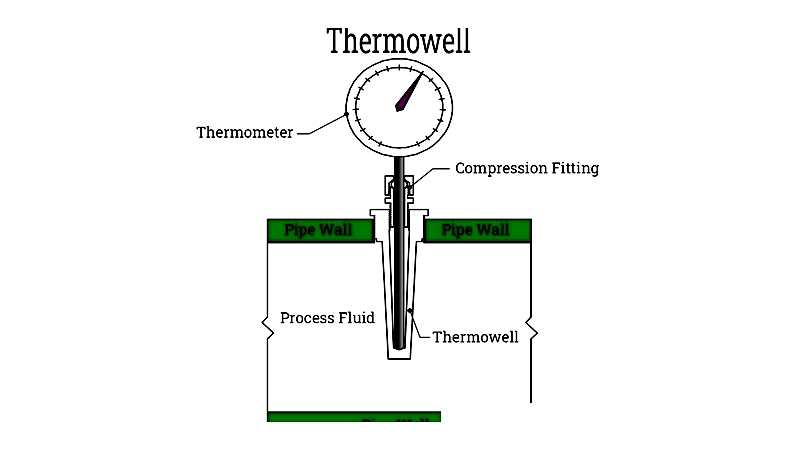

A thermowell is a pressure-resistant housing designed to protect temperature sensors in processing environments where direct sensor placement isn't feasible due to mechanical or chemical constraints. Installed directly into piping systems, thermowells enable sensor replacement in high-pressure pipelines without interrupting operations or requiring system drainage. Standardized thermowells also facilitate easy sensor removal and maintenance throughout the plant, improving process efficiency.

Thermowells shield temperature sensors—including bimetal thermometers, thermocouples, and thermistors—from corrosion, high velocities, and extreme pressures. This protection extends sensor lifespan and allows replacement without system drainage, reducing contamination risks. For high-pressure applications, thermowells are precision-machined from bar stock for durability, while lower-pressure versions may use tubing with welded ends.

How Thermowells Operate

Thermowells act as barriers between temperature sensors and process media, protecting against corrosive materials, pressurized substances, and rapid movement. They enable sensor removal while maintaining system integrity. Used in applications ranging from food industry cooking pots to brewing industry boilers, thermowells are essential where precise temperature control is critical.

The Critical Role of Thermowells

In industrial settings requiring precise temperature measurement, thermowells are indispensable. They protect sensors from harsh conditions like corrosion, high speeds, and extreme pressures, ensuring reliable and accurate readings.

- Shield sensors from corrosive elements

- Enable efficient heat transfer for accurate process temperature measurement

- Enhance accuracy through improved heat transfer in piping systems

- Allow sensor removal without disrupting system operation

Chapter 2: Thermowell Specifications, Designs, and Classification Systems

Thermowell Specifications

Selecting the optimal thermowell requires evaluating key specifications including material compatibility (e.g., stainless steel, carbon steel, Inconel), pressure/temperature ratings, mechanical strength, dimensions, insertion depth, and connection type. Compliance with standards like ASME PTC 19.3 TW and DIN is essential, along with verifying suitability for specific process conditions (corrosive media, high-velocity flow). Proper dimensions, vibration resistance, and wake frequency calculations ensure long-term durability and safety.

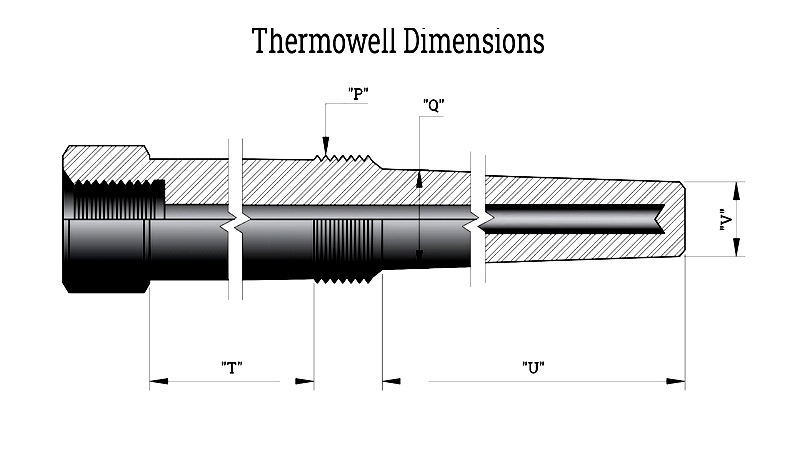

Root Dimension (Q): The thickest inserted part, correlating with process connection size and bore diameter.

Immersion Length (U): Distance from tip to connection base, ensuring reliable temperature readings with minimal thermal lag.

Bore Size (V): Internal diameter (typically 0.260" or 0.385") accommodating standard sensor sizes (0.25" or 0.38").

Lagging Extension (T): Portion extending beyond pipe wall for insulated systems, crucial for chilled water, HVAC, and cryogenic applications.

Hex Length (P): Distance from mounting threads to stem tip, facilitating tool-assisted installation.

Thermocouple Probe: metallic tube housing thermocouple wire, with sheath material (steel or corrosion-resistant alloys) ensuring close fit for optimal heat transfer.

Thermowell Installation

Proper installation is critical for accurate measurements and longevity. Key considerations include:

- Avoiding welding defects and incorrect dimension measurements

- Ensuring material compatibility with process media

- Maintaining minimal gap between thermowell ID and sensor OD

- Preventing vibration-induced failures through wake frequency calculations

For critical applications (steam lines, chemical processing, offshore facilities), engineered installation practices and periodic inspections are recommended.

Thermowell Designs

Effective designs consider process media, conditions, and these factors:

- Material selection (carbon steel, stainless steel, Inconel) balancing corrosion resistance and thermal sensitivity

- Wall thickness optimization for response time vs. strength

- Precise bore sizing for sensor fit and heat transfer

Common connection types include:

- Threaded

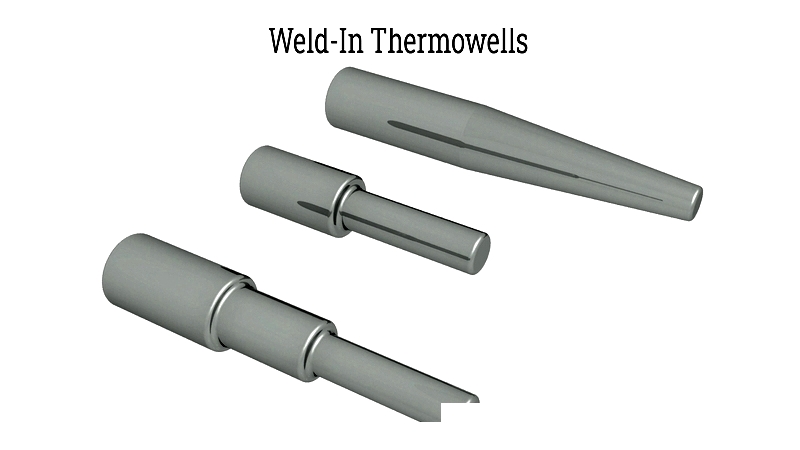

- Weld-in

- Socket weld

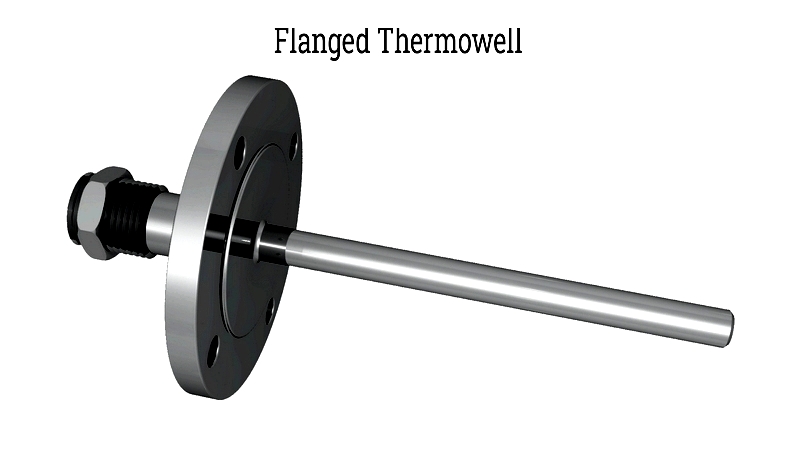

- Flanged

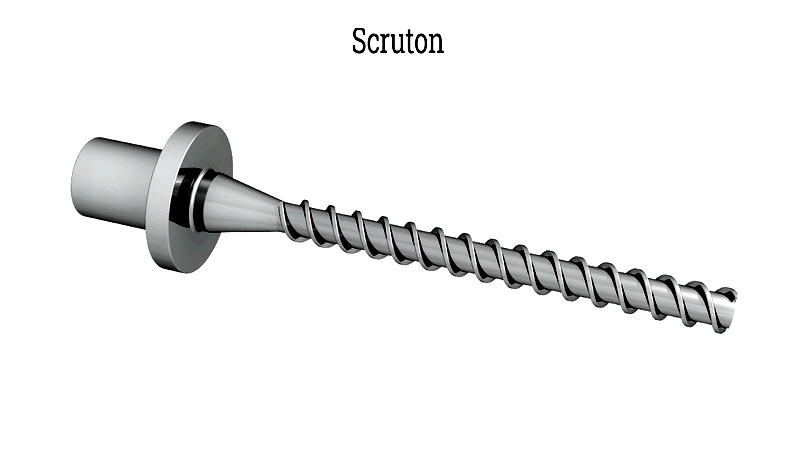

- Scruton

- Van Stone

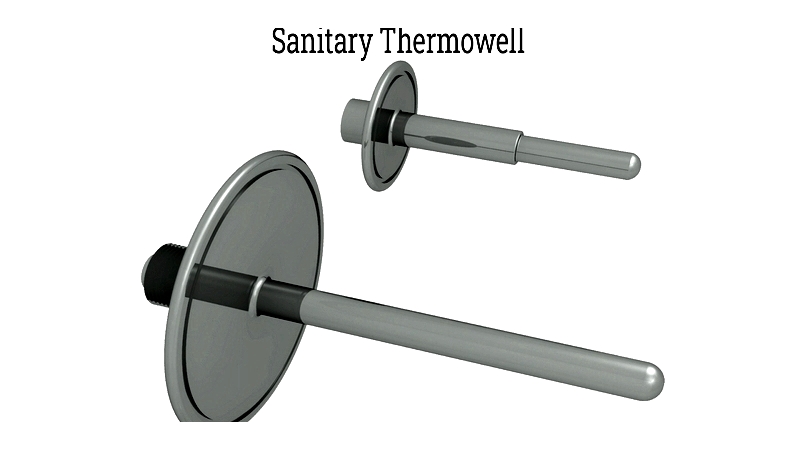

- Sanitary

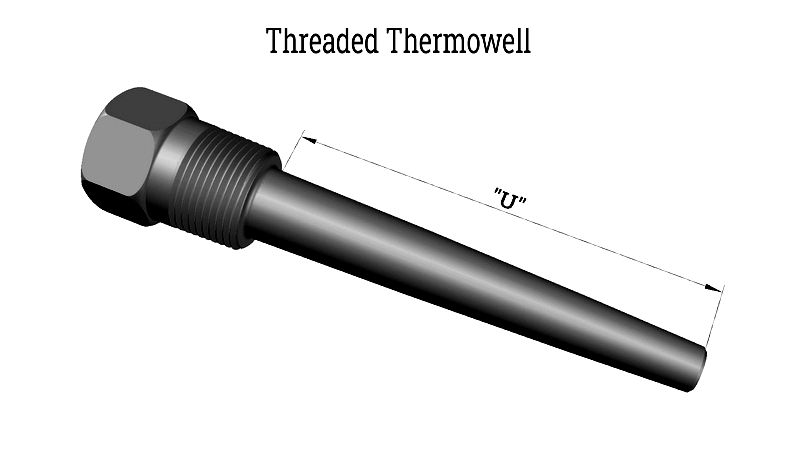

Threaded: Cost-effective for non-corrosive applications, installable via screwing into tapped pipes.

Socket-Welded: Permanent, high-temperature/pressure solution preferred in sanitary industries.

Van Stone: High-pressure design with serrated flange surfaces for precise fit in refineries/power plants.

Scruton: Helix design reducing vibration amplitude by 90%, ideal for petrochemical applications.

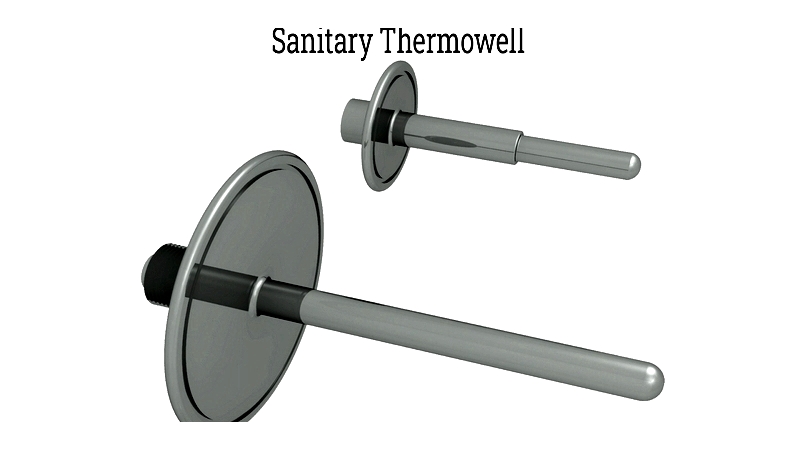

Sanitary: Hygienic connections (tri-clamp/sanitary flanges) meeting FDA/3-A standards for food/pharma.

Connection-based Types

Flanged: Extended collar for high-pressure/hazardous media, simplifying maintenance.

Weld-in: Permanent solution for high-temperature/pressure systems like refineries/chemical plants.

Threaded: Common in smaller pipelines (pulp/paper, refineries, power plants) for non-corrosive fluids.