Introduction

This article provides an in-depth examination of size reduction equipment.

It covers detailed information on various topics including:

- Principles of Size Reduction Equipment

- Types of Size Reduction Equipment

- Applications and Benefits of Size Reduction Equipment

- And more...

Chapter 1: Understanding the Principle of Size Reduction Equipment

This chapter explores the fundamental aspects of size reduction machinery, including their design, construction, and operational principles.

Defining Size Reduction Equipment

Size reduction machinery consists of devices designed to crush and grind materials, effectively reducing their dimensions. These machines, including pulverizers, play a crucial role in various industrial sectors by facilitating manufacturing and processing operations.

Manufacturers produce size reduction equipment capable of processing diverse materials such as coal, shale, brick, concrete, wood, limestone, and plastics. Different configurations are available to meet specific processing needs.

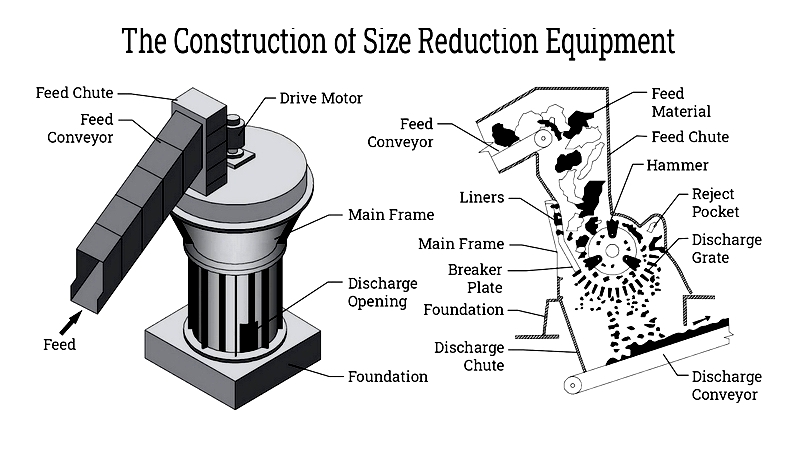

Structure of Size Reduction Equipment

Each size reduction machine is designed for specific throughput capacities based on factors like the Hardgrove Grindability Index (HGI), raw material volume, target particle size, and moisture content. These factors are critical for evaluating equipment performance. Proper fuel fineness and airflow are essential for optimal boiler combustion. Despite varying designs, all size reduction machines share basic components like grinding media and motor-driven rotary mechanisms.

Components: Grinding Media and Crushers

Frictional forces in size reduction machinery primarily come from grinding media, which may include non-sparking lead, ceramics, brass, bronze, and flint. Crushers are typically made from steel, stainless steel, or wear-resistant coated materials for enhanced durability.

Ceramic Materials

Ceramics are hard, brittle materials resistant to corrosion and heat, produced by firing inorganic materials like clay at high temperatures. Examples include porcelain, earthenware, and brick.

Certain elements like silicon or carbon can be classified as ceramics. These materials withstand chemical erosion and extreme temperatures (1,000°C to 1,600°C), making them ideal for high-temperature grinding. Advanced ceramics like tungsten carbide and silicon carbide offer exceptional abrasion resistance, commonly used in mining applications.

Non-Sparking Lead

Non-sparking lead, free from ferrous metals, prevents spark generation during grinding. Known for its ductility and corrosion resistance, lead provides durability in size reduction applications.

Brass: A Zinc and Copper Alloy

Brass, an alloy of zinc and copper, offers corrosion resistance and reduced friction. It is particularly useful in applications requiring spark reduction, such as milling operations.

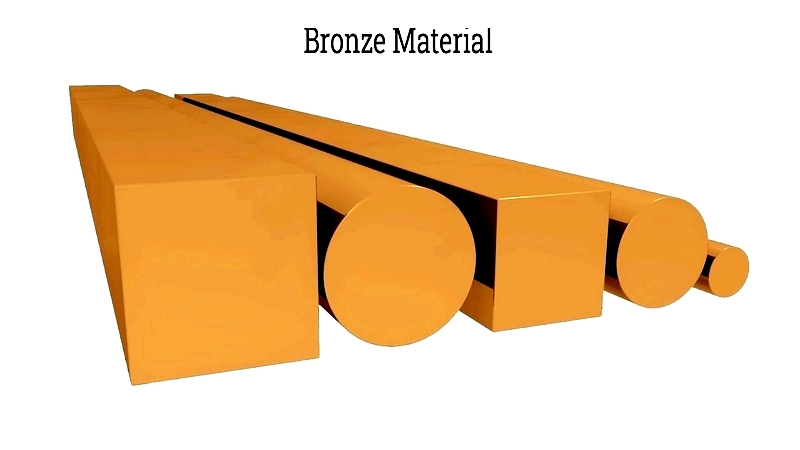

Bronze: A Copper Alloy

Bronze, primarily composed of copper and tin (12-12.5%), may include additional metals to enhance hardness and strength. Unlike steel, bronze does not generate sparks upon impact.

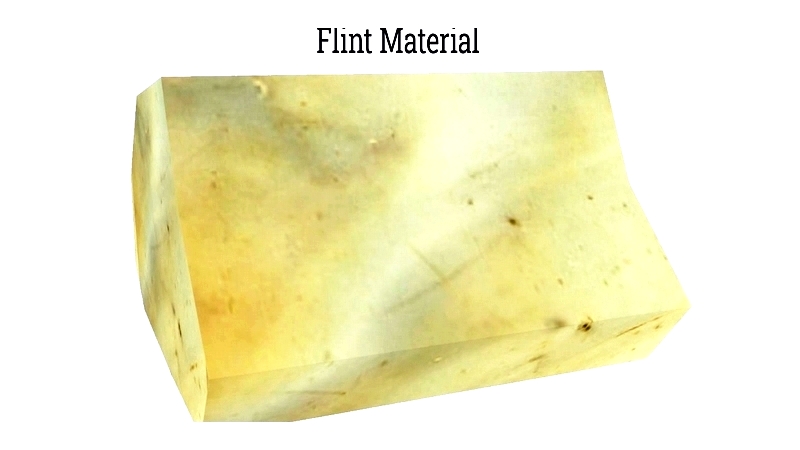

Flint Material

Flint, a type of crystalline quartz, is often used as grinding media in ball mills for ceramic production. Selected for its low chromophoric oxide content, it minimizes color impact on fired ceramics.

Steel Material

Steel, an iron-carbon alloy, provides enhanced strength and fracture resistance. It is shaped into balls or bars for use as crushing media in size reduction processes.

High carbon steel bars are effective for fine grinding but are less suitable for very hard materials. They excel with sticky substances that may cause ball clumping.

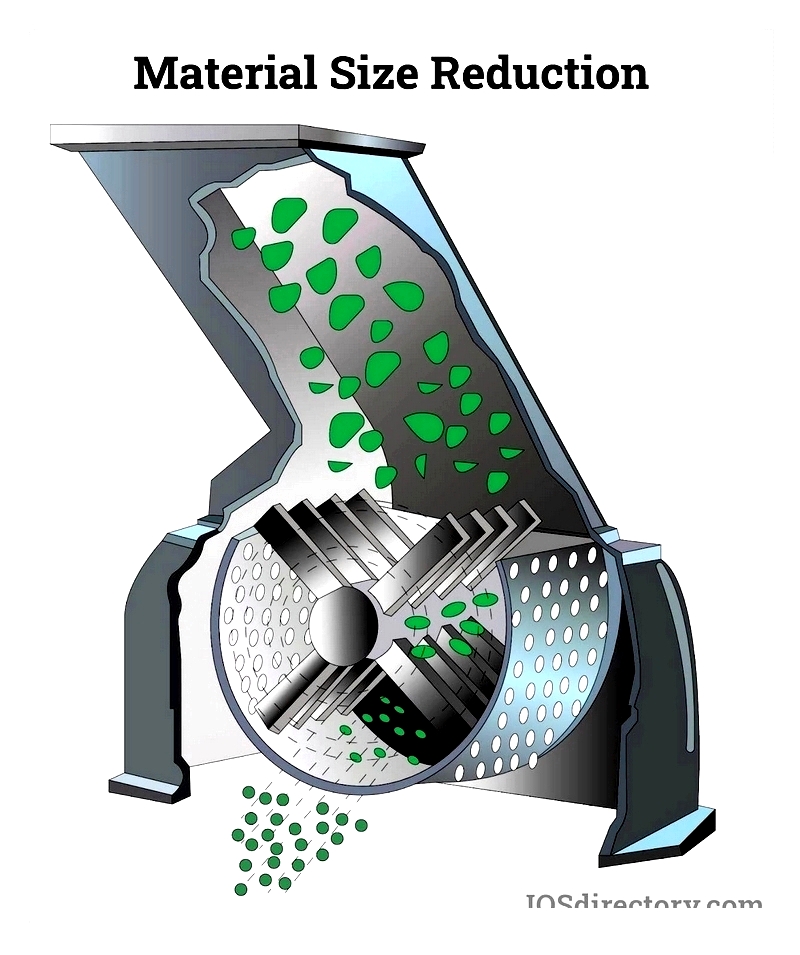

Operating Mechanism of Size Reduction Equipment

Pulverizers process materials continuously or in batches, using conveyor belts for feeding and rotating devices for crushing. Processed materials exit through discharge outlets, with optional features for heating, cooling, or ventilation.

Factors to Consider When Selecting Size Reduction Equipment

Key selection criteria include:

- Material properties

- Initial feed size

- Desired fineness

- Feed volume

For coarse initial samples, two-stage reduction may be necessary: primary reduction followed by fine grinding.

Choosing appropriate grinding tools involves evaluating abrasion resistance, hardness, energy input, and contamination risks.

Chapter 2: Types of Size Reduction Equipment

Size reduction equipment is vital across industries for breaking down materials, improving efficiency, and ensuring product consistency. These machines serve critical roles in mining, chemical production, food processing, pharmaceuticals, and recycling.

Pulverizers

Pulverizers crush and grind materials into smaller particles for industries like paper production, agriculture, and waste treatment. They process materials ranging from organic matter to plastics and rubber.

Main categories include impactors, crushers, and grinding mills. Impactors use high-speed collisions, crushers apply compressive force, and grinding mills employ friction and abrasion.

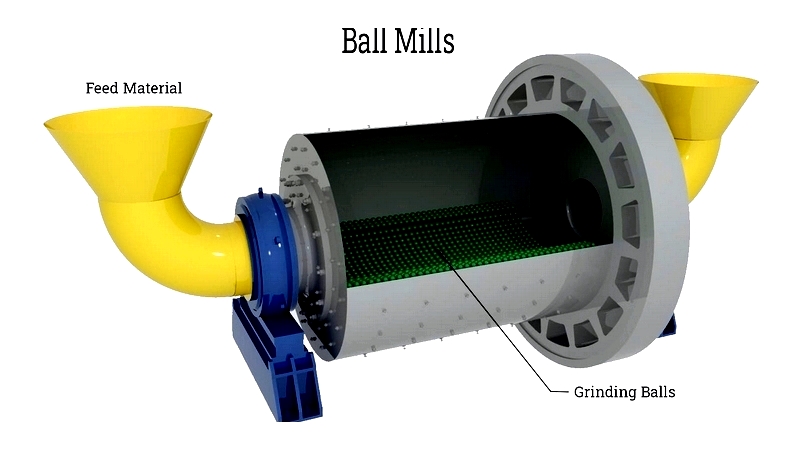

Ball Mills

Ball mills reduce hard or brittle materials using rotating drums filled with grinding media like steel balls or ceramics. They are essential in chemical, mining, and cement industries.

These mills improve material uniformity and aid chemical reactions. Modern systems offer continuous or batch operation with automated feeding.

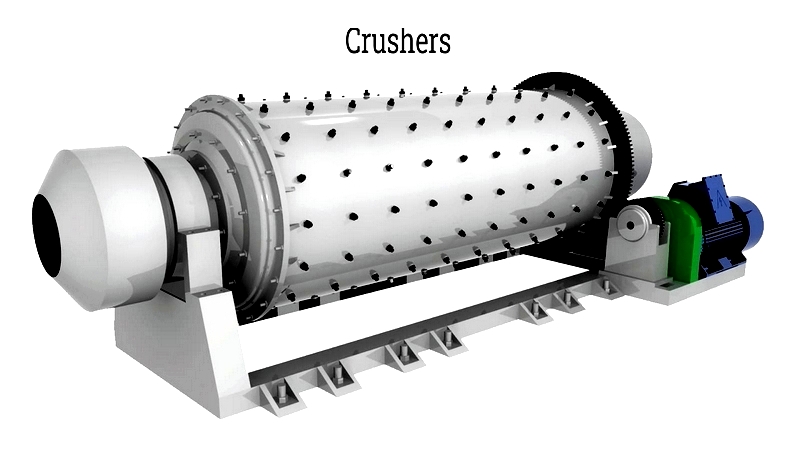

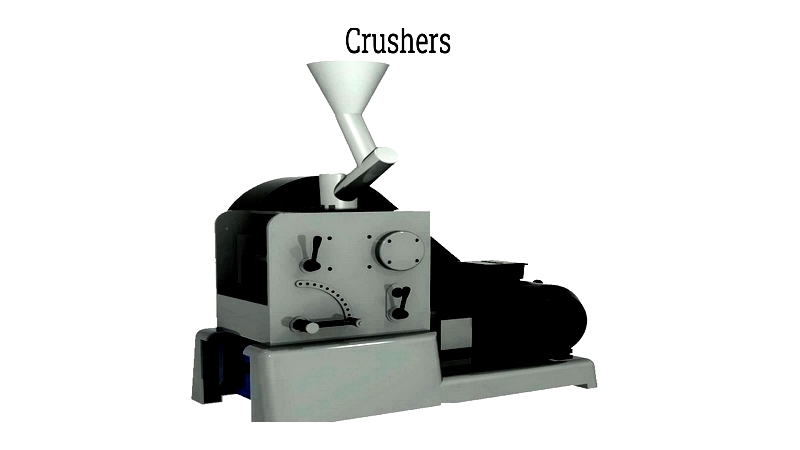

Crushers

Crushers break down large materials like rocks and ores for mining, construction, and recycling. Types include gyratory, cone, and jaw crushers.

Selection depends on material hardness, desired output, and production requirements.

Grinding Mills

Grinding mills produce fine powders for industries like cement, pharmaceuticals, and chemicals. Types include hammermills, ball mills, and jet mills.

Key factors include particle size needs, moisture content, and energy efficiency.

Impactor Machine

Impactors use high-velocity forces to create cubical particles for concrete and asphalt. They handle materials from limestone to coal.