Introduction

This is the most comprehensive online guide available about wire displays.

You'll discover:

- How Wire Displays Work

- Different Wire Display Varieties

- Materials for Wire Displays

- Practical Uses of Wire Displays

- Plus Additional Insights...

Chapter 1: Wire Display Fundamentals

This section explains wire displays, covering shaping processes and various formation techniques.

What Are Wire Displays?

Wire shaping accommodates diverse sizes, forms, and finishes. Custom wire forming creates functional structures through bending and molding.

Manufacturers use low-to-high-carbon steels, plus stainless steel, copper, aluminum, brass, and alloys.

Final shapes can be painted, plated, or coated as needed. Equipment includes CFR Ring Formers, BUW Welders, K-70 Welders, and CFM machines handling 17mm wire. CNC benders are common in retail, manufacturing, construction, automotive, and OEM industries.

Rebar enables skyscrapers; filaments power lamps; springs support furniture. Merchants use various wire displays in multiple sizes and alloys for specific needs.

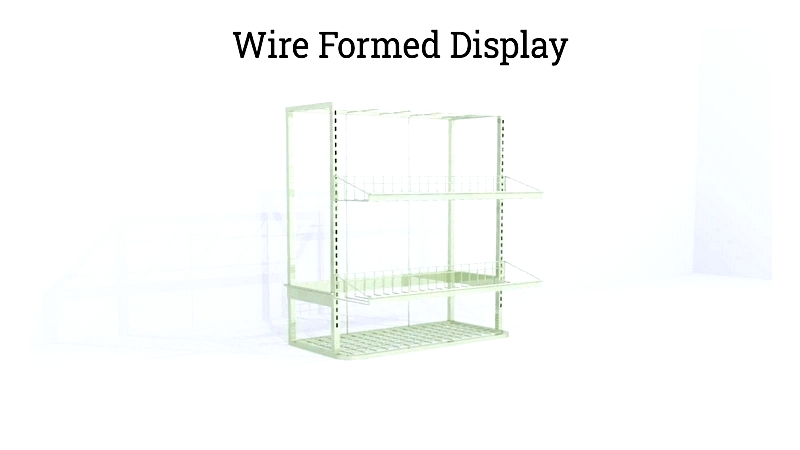

Products like wire shelves, display stands, baskets, and panels can be customized using advanced 2D/3D forming and welding machines.

The Wire Forming Process

Wire forming involves these key steps:

Selecting Appropriate Wire

CAD designs specify wire gauge, diameter, and type. Steel suits durable components; aluminum and copper work for lightweight uses.

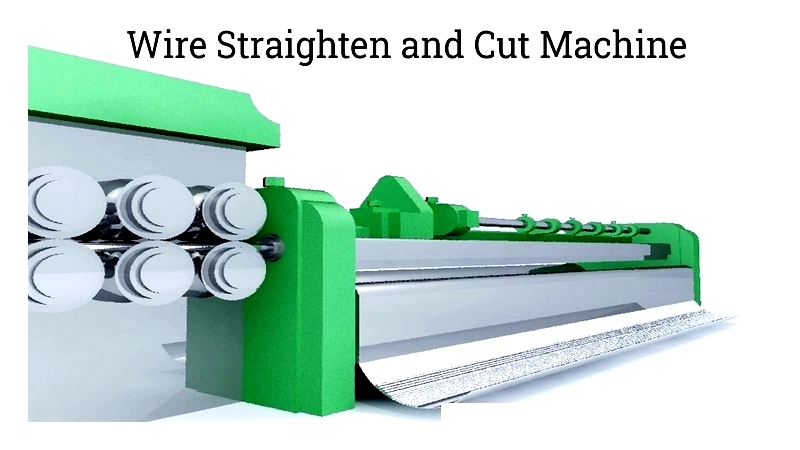

Straightening

Coiled wire requires straightening to remove storage-induced stress. Machine rolling achieves this - imperfections here affect final quality.

Applying Force

Force reshapes wire into required configurations. Methods range from manual to automated using dies and cutters. Mass production employs CNC and fourslide machines.

Surface Finishing

Some products need cutting, grooving, or edge smoothing for safety and function. Not all require finishing.

Wire Forming Methods

Various techniques create specific shapes:

Manual Forming

Traditional method using hand levers and spindles with drawn/rotary dies.

Coiling

Winds wire around blanks for springs or electrical coils. Precision varies by application.

Rolling

Cost-effective for creating flat, round, or shaped components with features like grooves or threads.

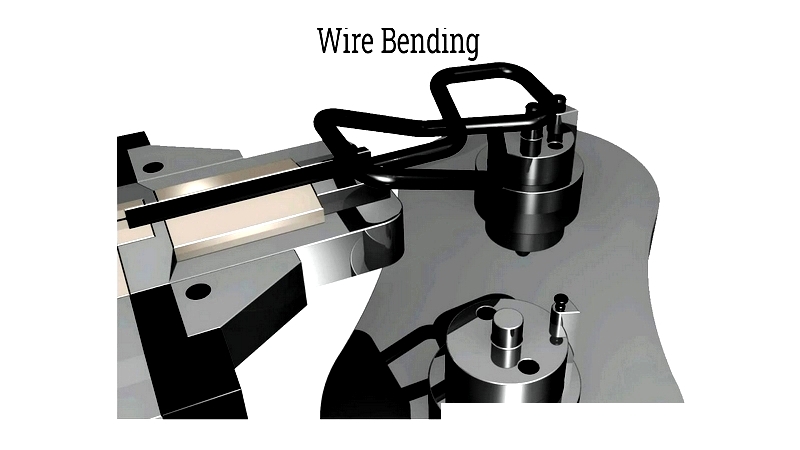

Bending

Forms wire into countless configurations (0.4-16mm diameters) without waste.

Fourslide

Uses cams and horizontal presses to shape wire from four directions simultaneously.

Hydraulic

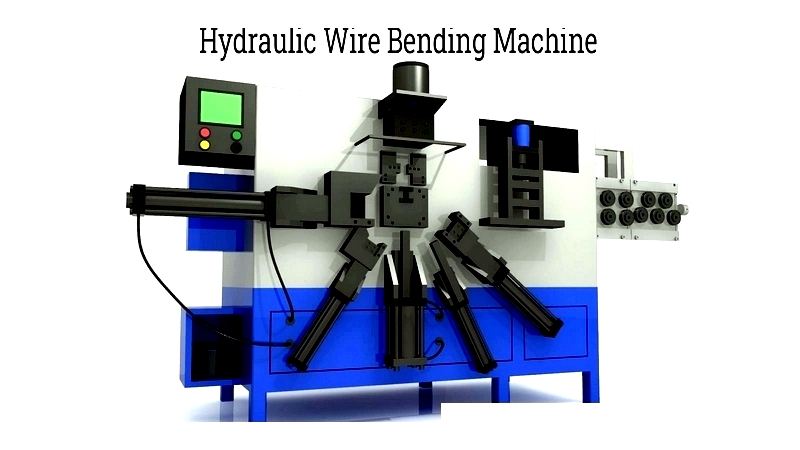

Hydraulic motors drive shaping rollers programmed via CNC for automated forming.

Pneumatic

Straightens, forms, and cuts wire using air pressure.

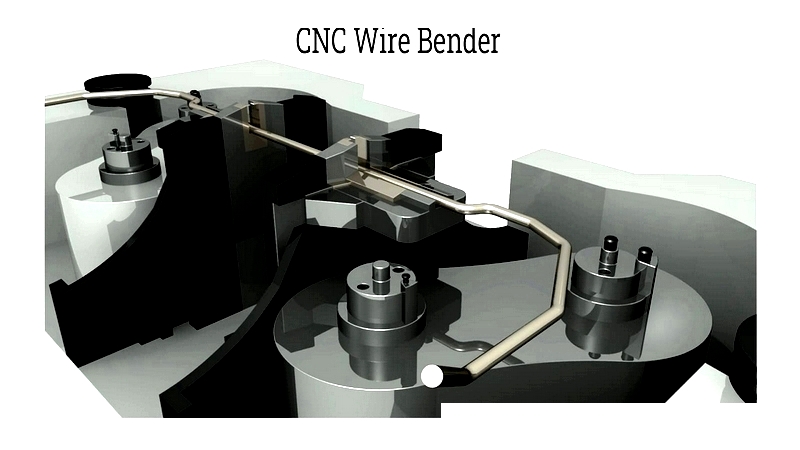

CNC Bending

Precision bending (up to 180°) with automatic straightening. Handles various metals (0.2-6.35mm diameters).

Chapter 2: Wire Display Types and Materials

This chapter examines wire display varieties for merchandising and the materials used in their construction.

Wire Display Categories

Common retail/commercial types include:

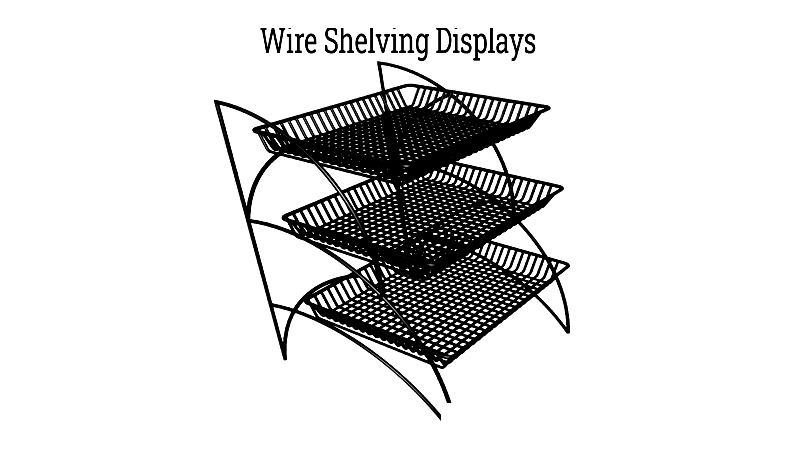

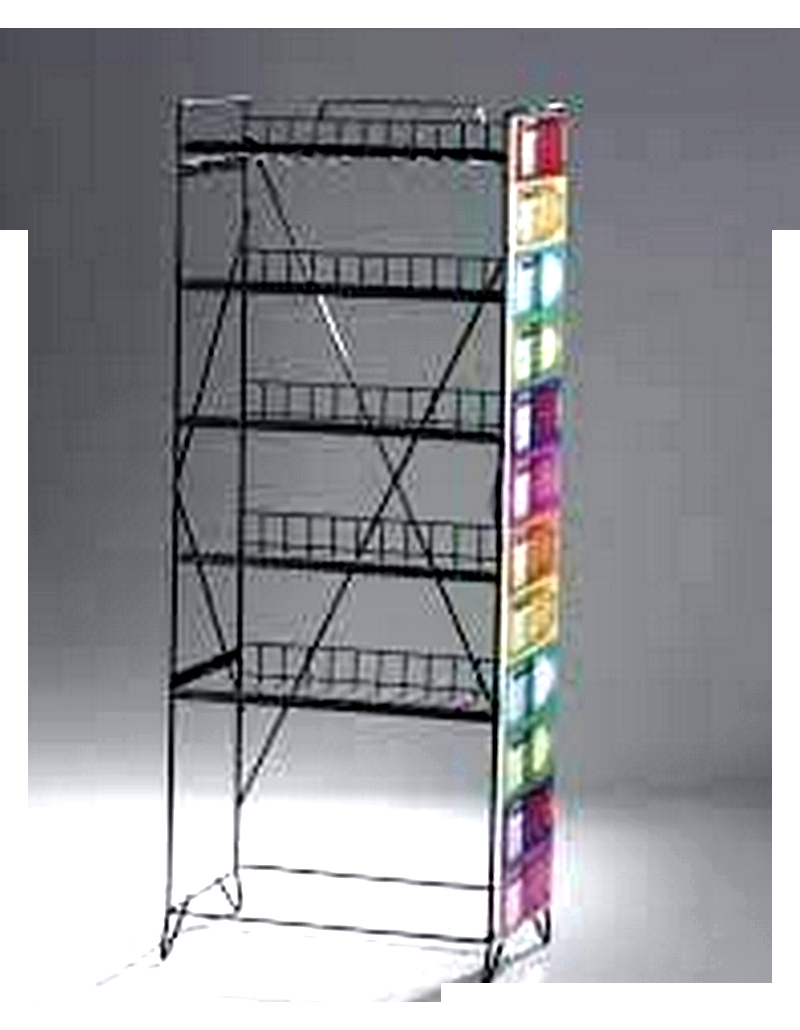

Floor Displays

Freestanding units with shelving for visual merchandising. Popular in supermarkets and hardware stores.

5-Shelf Bottle Display

Five-tier rack for beverages, tools, or books. Open design enhances visibility.

5 Shelf bottle Display from RFC Wire Forms

5 Shelf bottle Display from RFC Wire FormsWood/Wine Rack

Combines wooden shelves with steel supports for wine storage in liquor stores and restaurants.

Wire Cable Display

Hook-based unit for hanging cables in electronics/hardware stores.

4-Shelf Box Rack

Versatile storage for snacks, tools, or packaged goods.

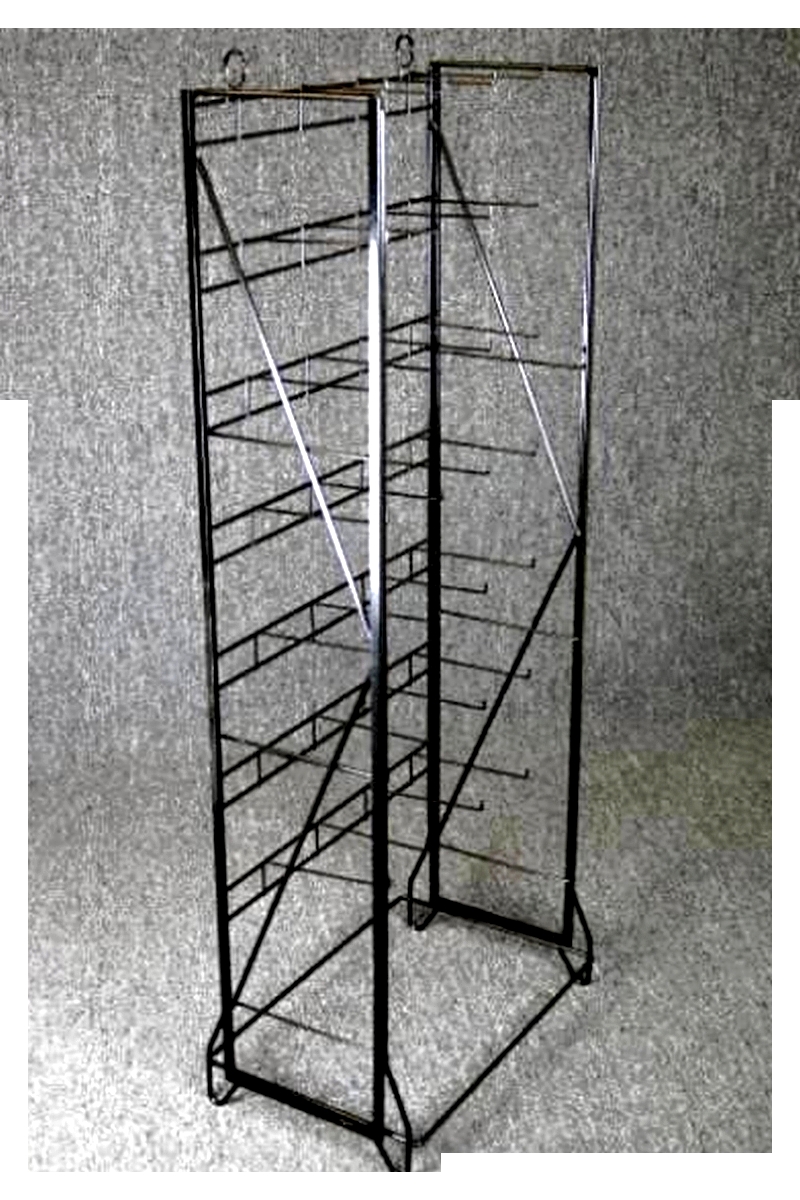

Hanging Bag Rack

Features hooks for bags/accessories in retail stores.

Hanging Bag Wire Display from RFC Wire Forms

Hanging Bag Wire Display from RFC Wire Forms6-Tier Snack Display

Compact unit for countertop snack or brochure organization.

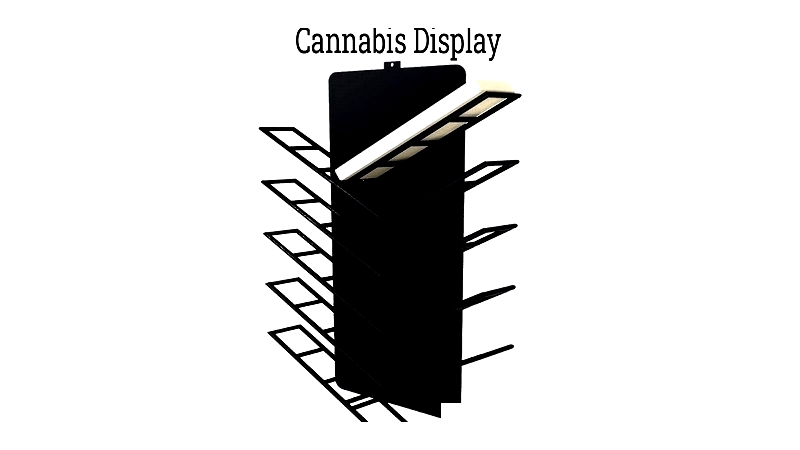

Cannabis Display

Wall-mounted grid units for dispensary product visibility.

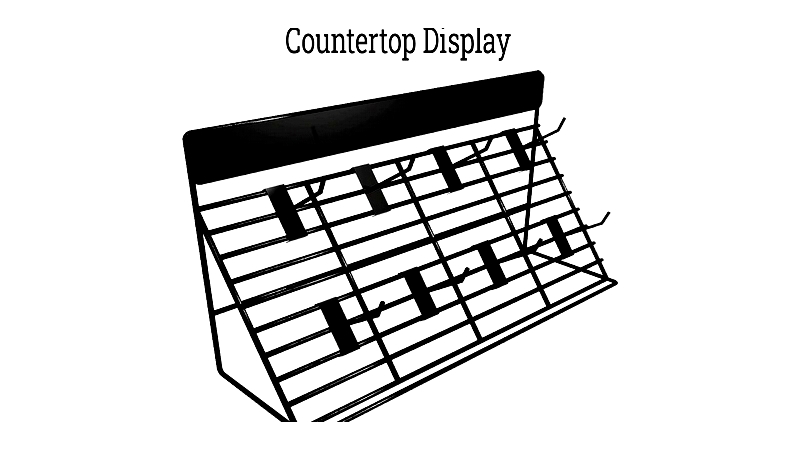

Countertop Displays

Compact units for POS items like snacks or cosmetics.

Newspaper Grid Racks

Steel wire stands (37"H x 16"W x 15"D) for periodicals in lobbies/stores.

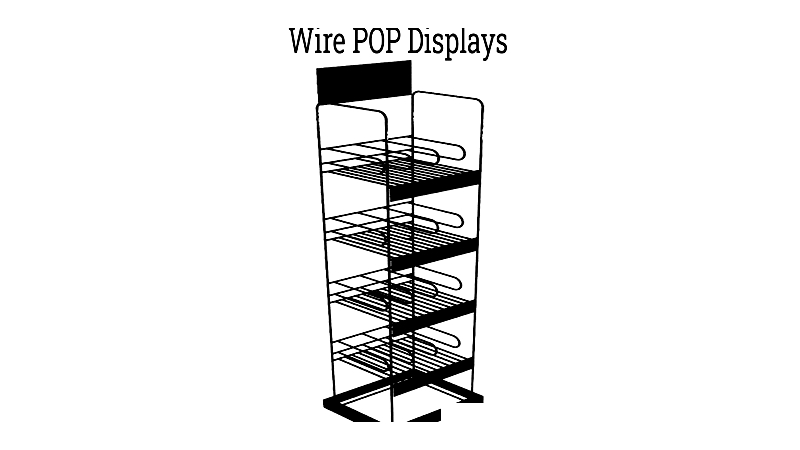

POP Displays

Promotional racks for impulse items. Often customizable with branding.

Brochure Displays

Countertop units for marketing materials in retail/office